Mesh belt furnace rapid carbon burning system

A mesh belt furnace, fast technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as damage to oxygen probe metal components, accelerated carbon deposition, incomplete carbon burning in the furnace, etc., and achieve the effect of rapid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

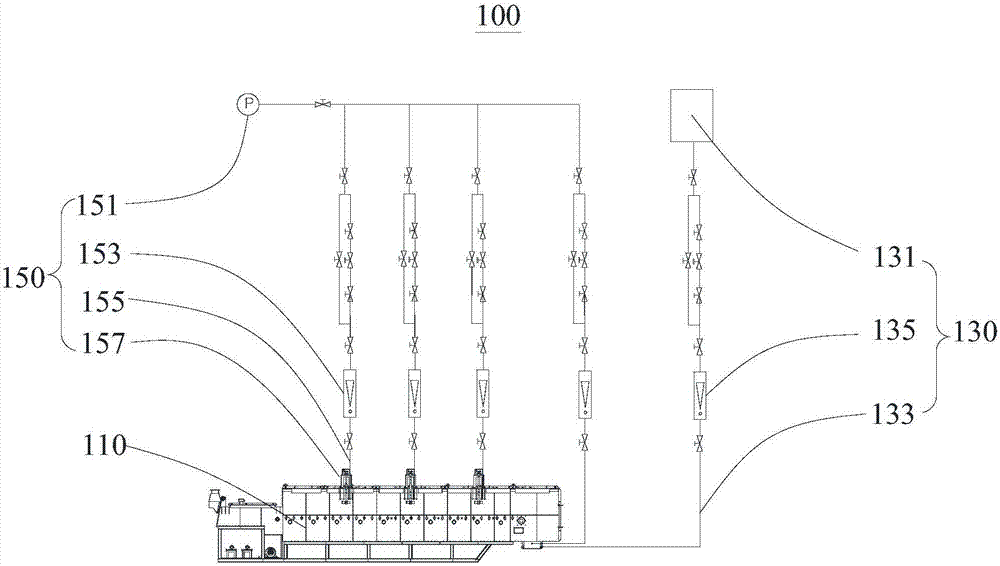

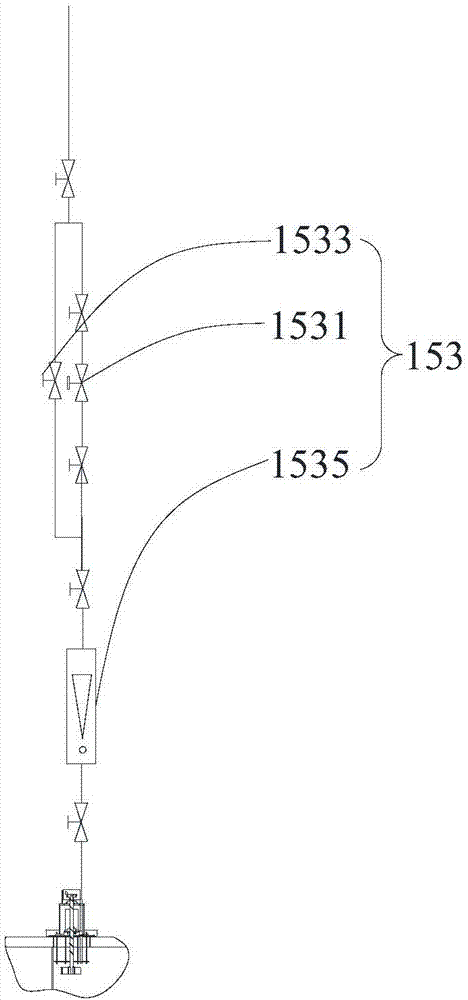

[0040] see figure 1 , the present embodiment provides a mesh belt furnace rapid carbon burning system 100, including a mesh belt furnace 110, a replacement gas device 130, a carbon burning device 150 and a control device 170 (see Figure 5 ), the replacement gas device 130 and the carbon burning device 150 are all connected with the mesh belt furnace 110, and the control device 170 is electrically connected with the replacement gas device 130 and the carbon burning device 150 respectively, for controlling the replacement gas device 130 to the mesh belt furnace 110 The inert gas is introduced, and it is also used to control the charcoal burning device 150 to pass into the mesh belt furnace 110 with normal pressure charcoal burning air.

[0041] It is worth noting that the mesh belt furnace rapid carbon burning system 100 is not only applicable to the continuous mesh belt furnace 110, but also can be used in other forms of heat treatment devices such as roller furnaces or roller...

no. 2 example

[0059] This embodiment provides a mesh belt furnace rapid carbon burning system 100. Its basic structure, principle and technical effects are the same as those of the first embodiment. For a brief description, for the parts not mentioned in this embodiment, please refer to the first Corresponding content in an embodiment. The difference between this embodiment and the first embodiment is that the carbon burning fan 151 is replaced by an air compressor (not shown).

[0060] The mesh belt furnace rapid carbon burning system 100 includes a mesh belt furnace 110 , a gas replacement device 130 and a carbon burning device 150 , and both the gas replacement device 130 and the carbon burning device 150 are connected to the mesh belt furnace 110 .

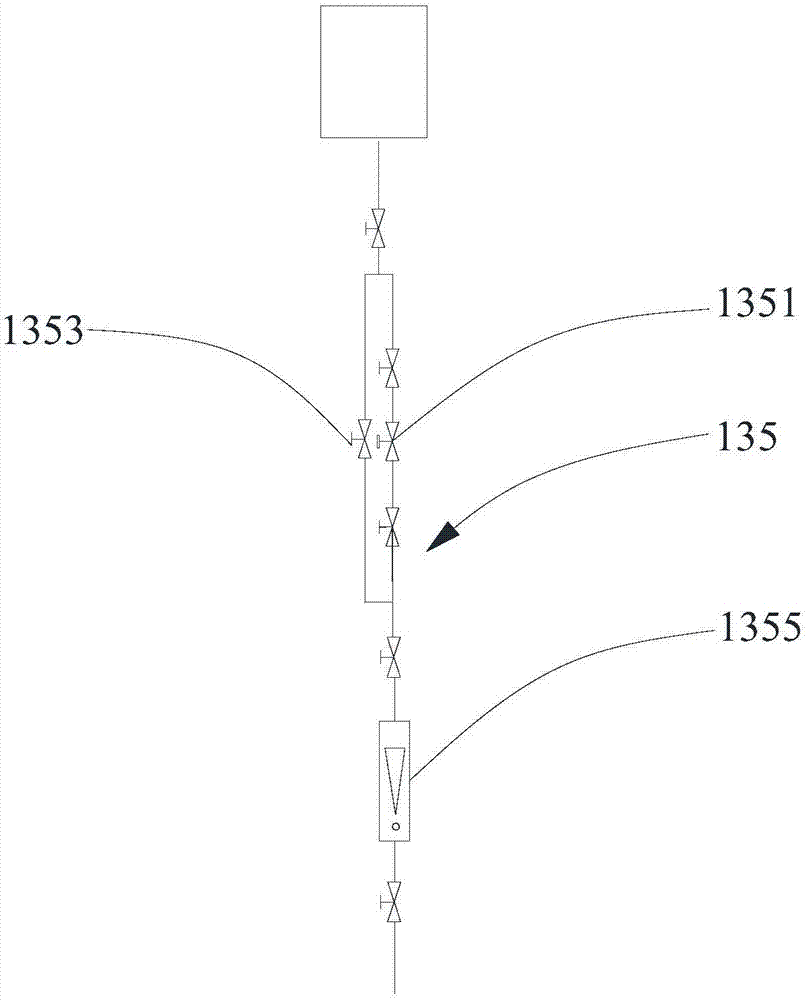

[0061] The replacement gas device 130 includes an inert gas source 131, a jet pump, a purge pipeline 133, and a first flow regulating assembly 135. The inert gas source 131 is connected to the jet pump through the purge pipeline 133, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com