Fixed-point gas outlet method

An air outlet device and air pill technology, applied in electrical components, spark gaps, spark gap parts, etc., can solve the problem of poor arc extinguishing effect, achieve the effect of arc extinguishing effect, improve safety capability, and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

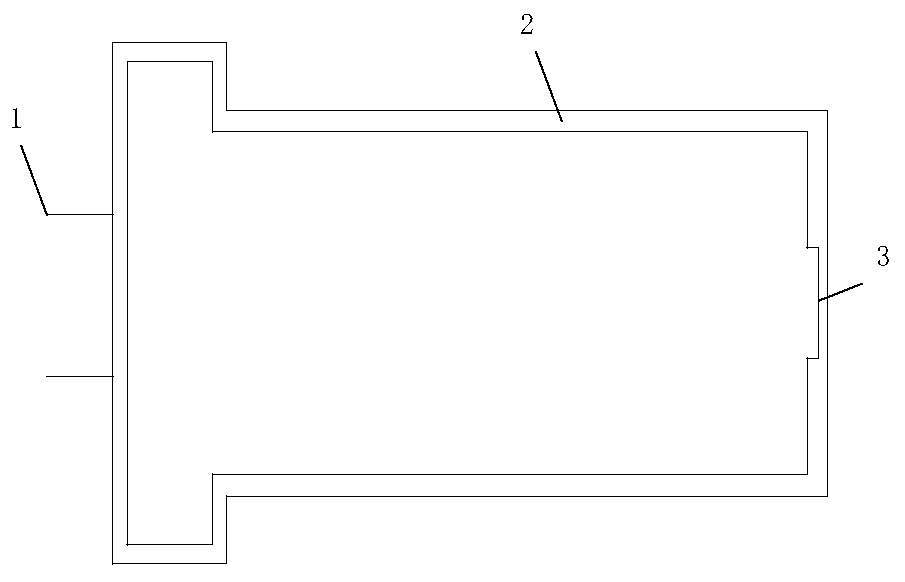

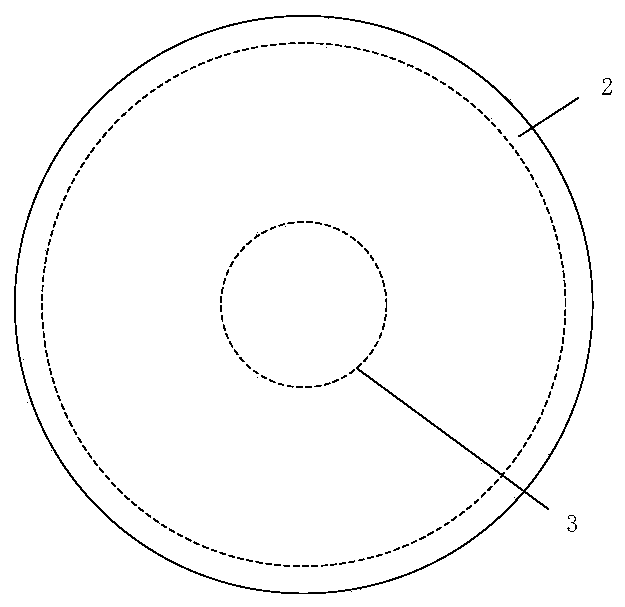

[0034] Such as figure 1 , 2 As shown, the thickness of the steel shell 2 is evenly distributed in other parts, but a directional gas outlet portion 3 is provided at the bottom of the gas pill, and the thickness of the steel shell 2 at this place is relatively thin, so that the gas produced after the gas-producing fuel is burned The gas is ejected directionally from the weak point of the gas outlet. The air outlet part is located at the bottom of the air pill, which is round in shape with a diameter of about 5-6mm. The outside of the steel shell at the air outlet is flush with the periphery, and the inside of the steel shell at the air outlet is lower than the periphery.

Embodiment 2

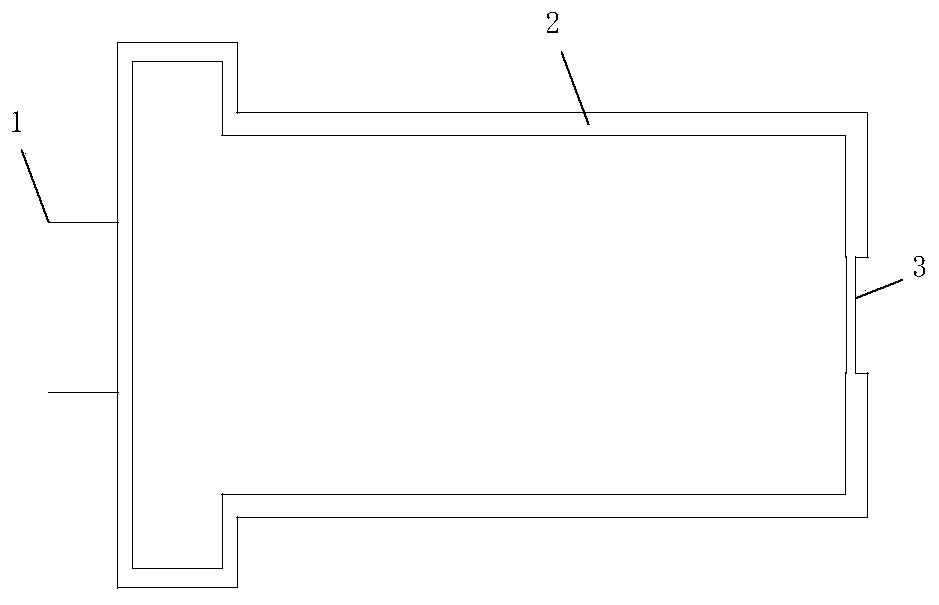

[0036] Such as image 3 , 4As shown, the thickness of the steel shell 2 is evenly distributed in other parts, but a directional gas outlet part 3 is provided at the bottom of the gas pill, and the thickness of the steel shell at this place is relatively thin, so that the gas produced after the combustion of the gas-producing fuel is released from the The weak point of the air outlet is directed to spray. The air outlet part is located at the bottom of the air pill, which is round in shape with a diameter of about 5-6mm. The outer side of the steel shell at the air outlet is lower than the periphery, and the inner side of the steel shell at the air outlet is flush with the periphery.

Embodiment 3

[0038] Such as Figure 5 , 6 As shown, the air outlet at the bottom of the steel shell is a through hole, the through hole is circular, and the inner diameter is about 5-6mm. A directional bucket 5 protrudes downwards from the through hole at the bottom of the steel shell, and the length of the directional bucket is about 5-8mm. A circular aluminum plate 4 is designed at the bottom of the air pill and inside the steel shell. The diameter of the aluminum plate 4 is the same as the inner diameter of the steel shell, and the thickness of the aluminum plate is about 2-5mm. The connection between the aluminum plate 4 and the steel shell can be pressed or welded. A sealed space is formed, and gas-producing fuel is placed inside the sealed space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com