Polymethyl methacrylate polymer and preparation method thereof

A technology of polymethyl methacrylate and methyl methacrylate is applied in the field of heat-resistant reinforced polymethyl methacrylate monomer and its preparation, and achieves environmental protection, low energy consumption, guaranteed product quality, and good light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Steps:

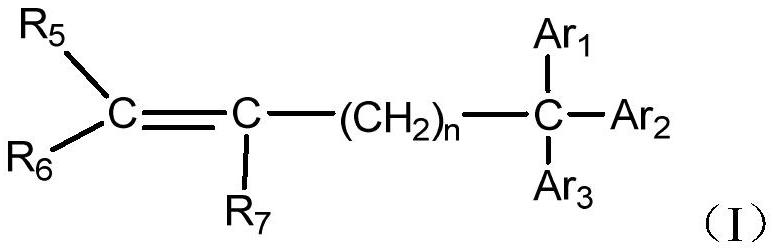

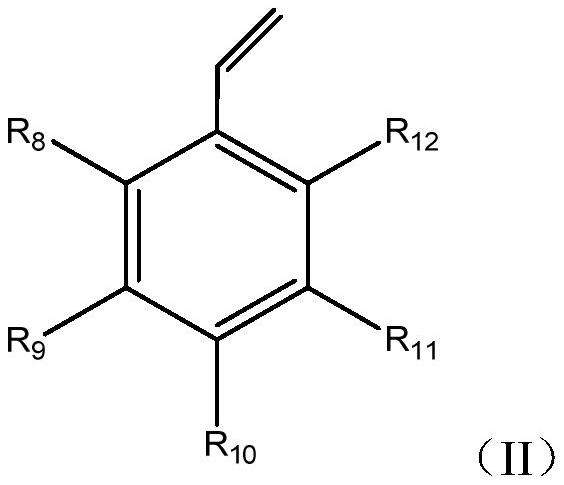

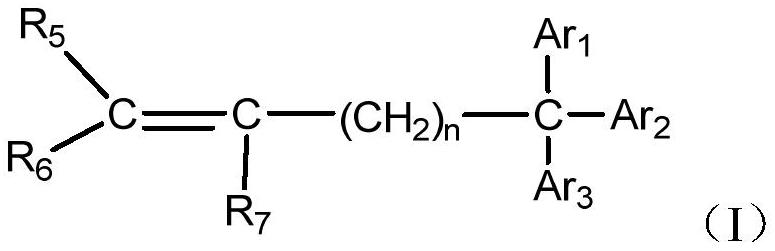

[0059] (1) Ingredients: take 80 parts of monomer I methyl methacrylate, 14 parts of monomer II vinyl monomer containing triphenyl structure, 6 parts of monomer III p-divinylbenzene, initiator diphenyl peroxide 0.18 part of formyl, 0.15 part of chain transfer agent tert-dodecyl mercaptan, fully stirred until they were mixed evenly, added to the reaction kettle, and passed nitrogen for 20 minutes to remove the oxygen dissolved in it;

[0060] (2) Step-by-step polymerization: control the reaction temperature to 90°C, react under stirring for 40min, move the polymer in the reactor into a low-temperature reaction vessel, control the reaction temperature to 50°C, and the reaction time to 32h, and further heat up to 90°C, 105°C, 120 ° C, each temperature was reacted for 2 hours, the polymerization conversion rate was improved, and the residual monomer was reduced.

Embodiment 2

[0062] Steps:

[0063] (1) batching: take 85 parts of monomer I methyl methacrylate, 9 parts of monomer II vinyl monomer containing triphenyl structure, 6 parts of monomer III p-divinylbenzene, initiator diphenyl peroxide 0.18 part of formyl, 0.15 part of chain transfer agent tert-dodecyl mercaptan, fully stirred until they were mixed evenly, added to the reaction kettle, and passed nitrogen for 20 minutes to remove the oxygen dissolved in it;

[0064] (2) Step-by-step polymerization: control the reaction temperature to 90°C, react under stirring for 40min, move the polymer in the reactor into a low-temperature reaction vessel, control the reaction temperature to 50°C, and the reaction time to 32h, and further heat up to 90°C, 105°C, 120°C, respectively, at each temperature for 2 hours to increase the polymerization conversion rate.

Embodiment 3

[0066] Steps:

[0067] (1) Ingredients: take 90 parts of monomer I methyl methacrylate, 6 parts of monomer II vinyl monomer containing triphenyl structure, 4 parts of monomer III p-divinylbenzene, initiator diphenyl peroxide 0.18 part of formyl, 0.15 part of chain transfer agent tert-dodecyl mercaptan, fully stirred until they were mixed evenly, added to the reaction kettle, and passed nitrogen for 20 minutes to remove the oxygen dissolved in it;

[0068] (2) Step-by-step polymerization: control the reaction temperature to 90°C, react under stirring for 40min, move the polymer in the reactor into a low-temperature reaction vessel, control the reaction temperature to 50°C, and the reaction time to 32h, and further heat up to 90°C, 105°C, 120 ° C, respectively, at each temperature for 2 hours to reduce residual monomers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com