Industrial flow anti-misoperation system and industrial flow anti-misoperation method

A technology of error prevention and process, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve problems such as production stoppage, decreased judgment, personal injury and death

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

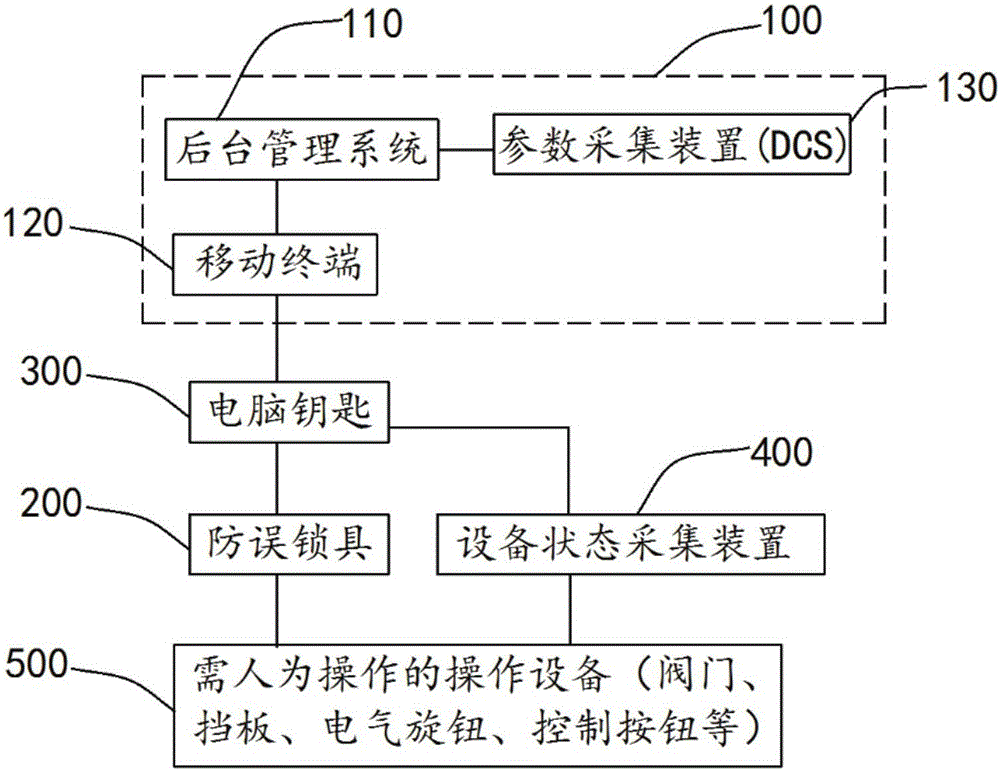

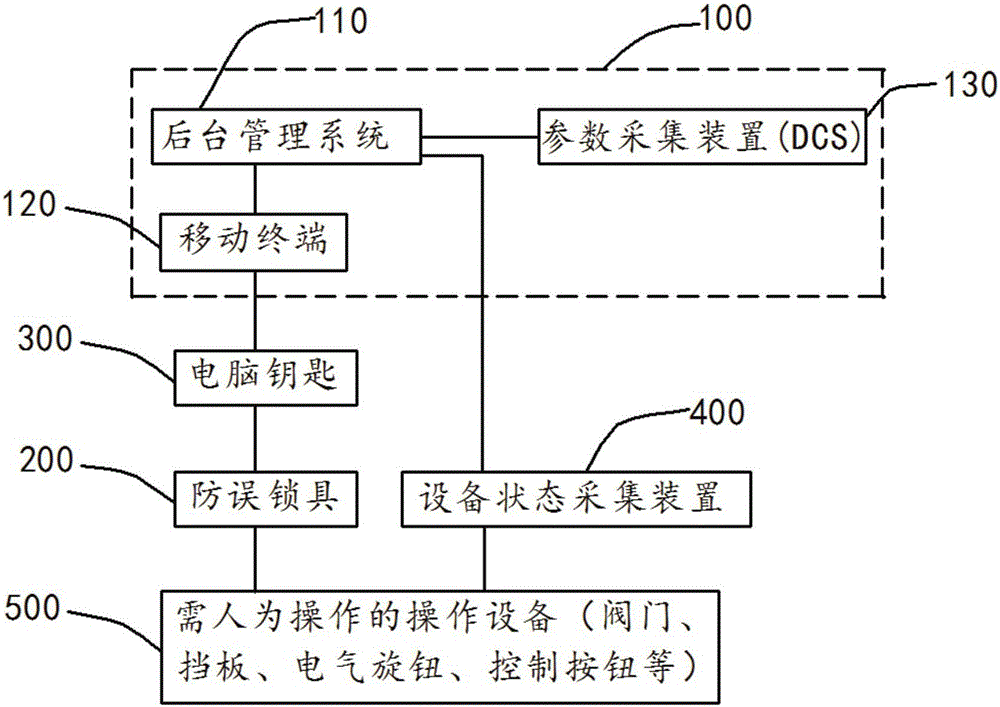

[0058] In order to illustrate the technical solution of the present invention more clearly, the following in conjunction with the attached Figure 1 to Figure 4 The specific embodiment of the present invention will be further described in detail.

[0059] Such as figure 2 with image 3 Shown is a schematic diagram of the structure of the anti-error system of the industrial process provided by the embodiment of the present invention. The connection lines of the components in the figure represent the relationship between each other. Please combine the diagram and the text for the connection relationship and interaction relationship of the components Description for understanding.

[0060] This embodiment provides an error prevention system for an industrial process, including a control system 100, an error prevention lock 200, a computer key 300, and an equipment status acquisition device 400. In this embodiment, the control system 100 includes a background management system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com