Process and device for extracting citral from Litsea cubeba oil

A technology of litsea cubeba oil and citral, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of high impurity content, achieve high purity, short heating time, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

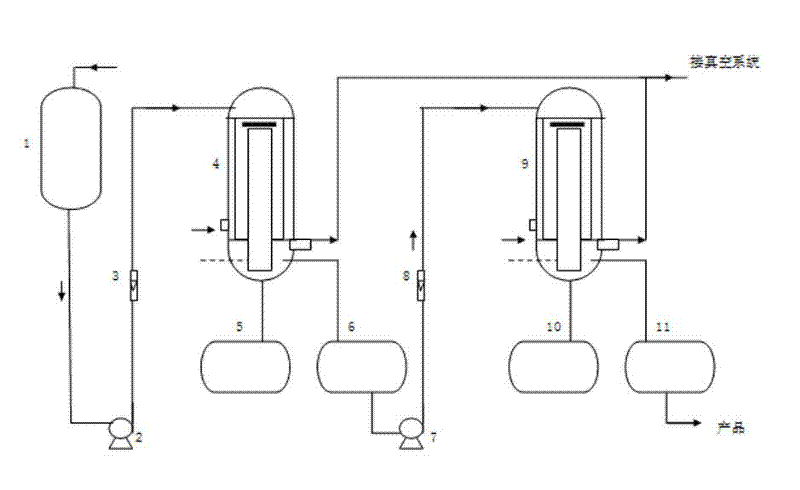

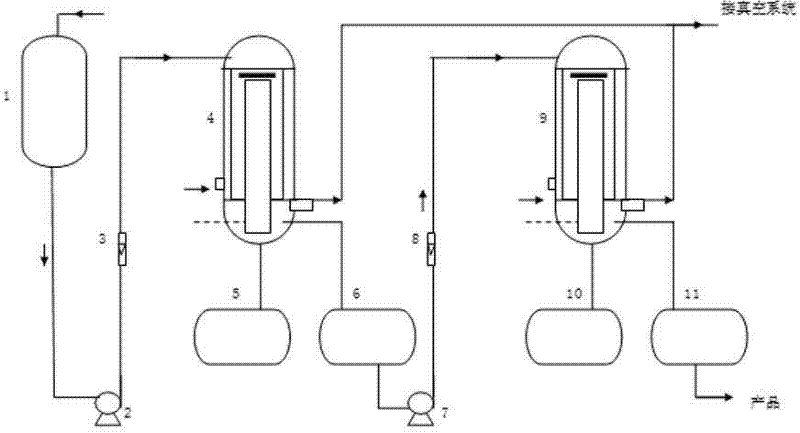

[0019] Embodiment 1: the device embodiment that extracts citral from litsea cubeba oil

[0020] refer to figure 1 , the present invention extracts the device embodiment of citral from litsea cubeba oil and comprises raw material tank 1, metering pump 2. Rotameter 3. Primary molecular still 4. Distillate intermediate storage tank 5. Distillate residue storage tank intermediate storage tank 6. Metering pump 7. Rotameter 8. Secondary molecular still 9, distillate storage tank 10, and distillate storage tank 11, vacuum system, heating system and cooling water system; in raw material tank 1 and rotameter 3 with metering pump 2. Metering pump The inlet of 2 is connected with the outlet of raw material tank 1, and the metering pump 2 outlets with rotameter 3 inlets connected, rotameter The outlet of 3 is connected with the inlet of the upper part of the primary molecular still 4, and the lower part of the primary molecular still has distillate and distilla...

Embodiment 2

[0027] The operating conditions of this example are: in the selected raw material Litsea cubeba oil, the mass fraction of citral is 70.2%, the primary distillation temperature is 40°C, the pressure is 100Pa, the secondary distillation temperature is 65°C, and the pressure is 1Pa. The mass fraction of citral discharged from the bottom of the secondary molecular still was 97.9%.

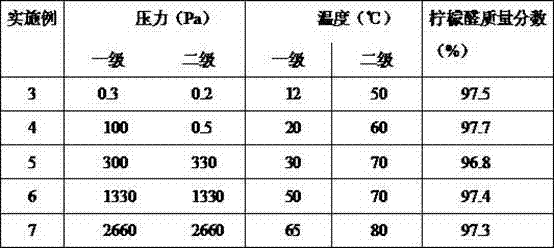

Embodiment 3~7

[0029] The process condition data of each step of Examples 3 to 6 and the mass fraction of citral in the product are shown in Table 1.

[0030] Table 1 The process conditions of each step in Examples 3 to 6 and the mass fraction of citral in the product

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com