Method for preparing carbon black and active carbon from waste tyre pyrolytic carbon

A technology for waste tires and activated carbon is applied in the field of preparing carbon black and activated carbon from waste tire pyrolysis carbon, which can solve the problems of high equipment requirements and high energy consumption, and achieve the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

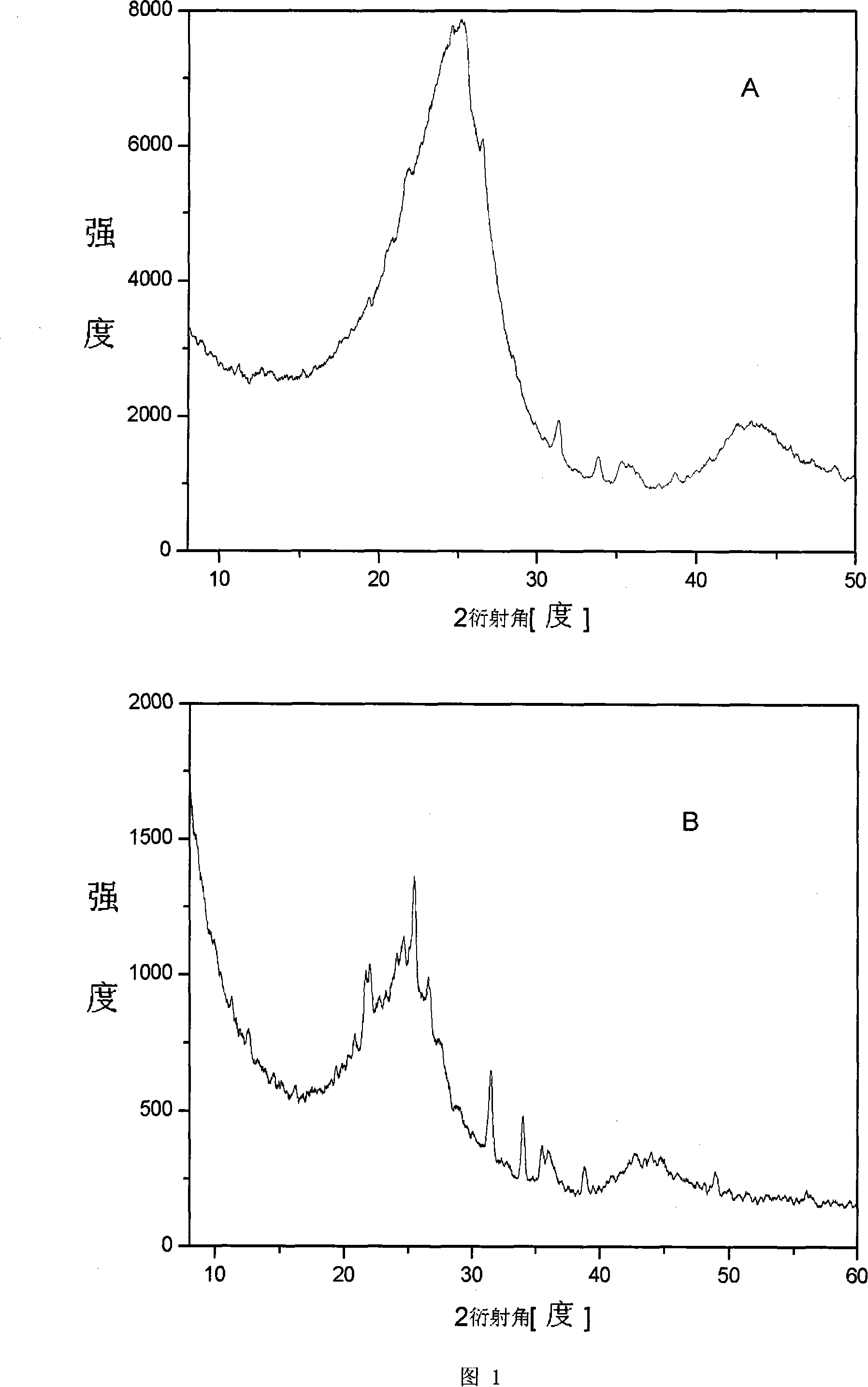

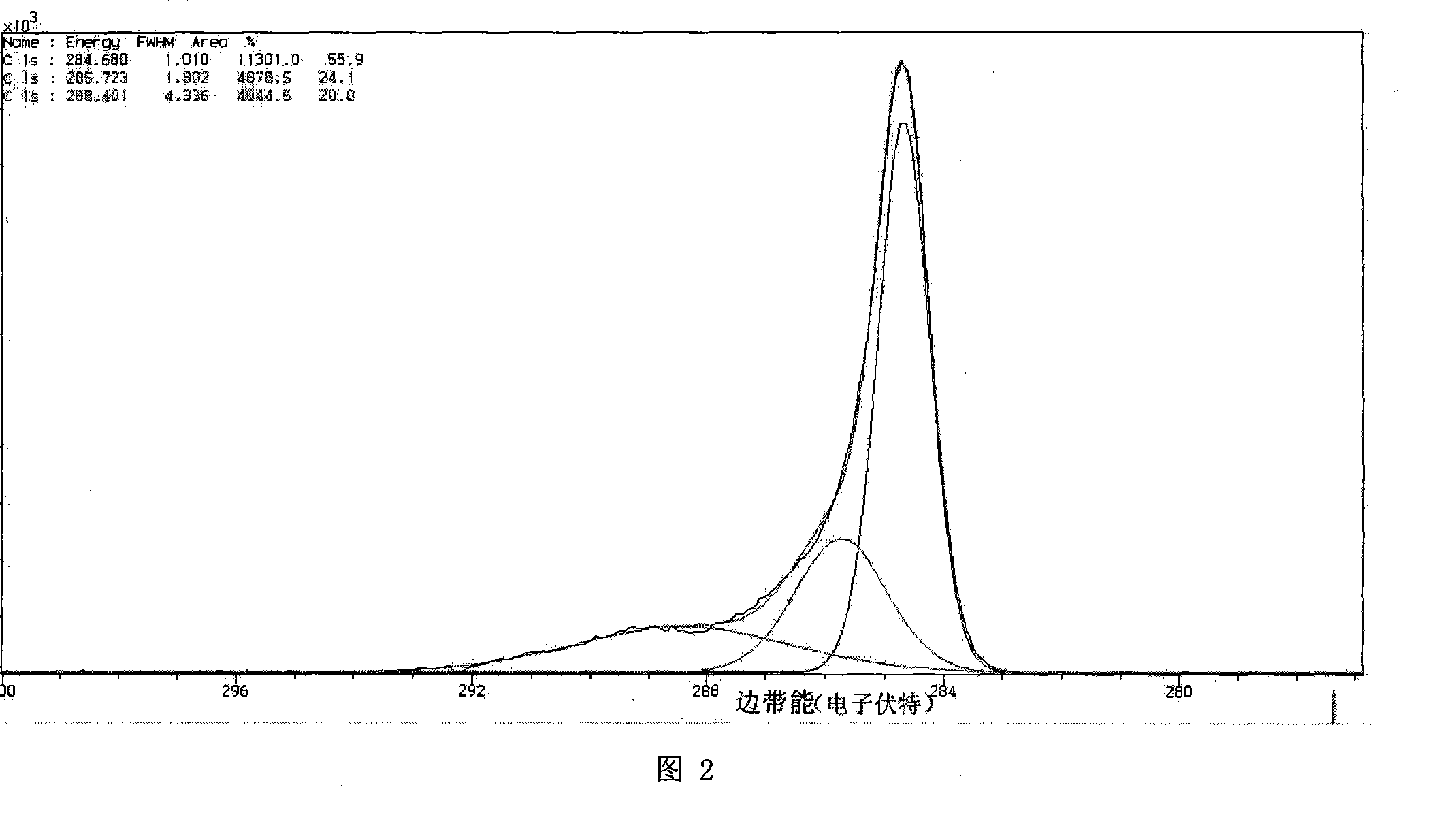

Embodiment 1

[0025] Take 1g of waste tire pyrolysis carbon black powder and put it into a paper bag sewn by filter paper, put it in the reflux tube of the Soxhlet extractor, put 100ml of toluene into the round bottom flask, carry out Soxhlet extraction for 8 hours, pass the liquid through The organic solvent was removed by rotary distillation, and the oil in the waste tire pyrolysis carbon black was collected. Remove the paper bag containing the sample to dry and collect the dried solid. Take 1 g of the solid and 30 ml of dilute sulfuric acid with a concentration of 0.1 mol / L and put them into a round bottom flask, stir at 30° C. for 0.5 hour, filter with suction, repeat the above steps twice, and finally dry the solid obtained by suction filtration. Take the dried solid and put it into a quartz boat, put it into the quartz tube of the electric tube furnace, connect a round bottom flask filled with distilled water at one end of the quartz tube, heat and boil the distilled water, and treat ...

Embodiment 2

[0027] Take 1g of waste tire pyrolysis carbon black powder and put it into a paper bag sewn by filter paper, put it in the reflux tube of the Soxhlet extractor, put 100ml of toluene into the round bottom flask, carry out Soxhlet extraction for 8 hours, pass the liquid through The organic solvent was removed by rotary distillation, and the oil in the waste tire pyrolysis carbon black was collected. Remove the paper bag containing the sample to dry and collect the dried solid. Take 1 g of the solid and 30 ml of dilute sulfuric acid with a concentration of 0.1 mol / L and put them into a round bottom flask, stir at 30° C. for 0.5 hour, filter with suction, repeat the above steps twice, and finally dry the solid obtained by suction filtration. Take the dried solid and put it into a quartz boat, put it into a quartz tube of a tube-type electric furnace, connect a round bottom flask filled with distilled water at one end of the quartz tube, heat and boil the distilled water, and treat...

Embodiment 3

[0029]Take 1g of waste tire pyrolysis carbon black powder and put it into a paper bag sewn by filter paper, put it in the reflux tube of the Soxhlet extractor, put 100ml of toluene into the round bottom flask, carry out Soxhlet extraction for 8 hours, pass the liquid through The organic solvent was removed by rotary distillation, and the oil in the waste tire pyrolysis carbon black was collected. Remove the paper bag containing the sample to dry and collect the dried solid. Take 1 g of the solid and 30 ml of dilute sulfuric acid with a concentration of 0.1 mol / L and put them into a round bottom flask, stir at 30° C. for 0.5 hour, filter with suction, repeat the above steps twice, and finally dry the solid obtained by suction filtration. Take the dried solid and put it into a quartz boat, put it into the quartz tube of the tube electric furnace, connect a round bottom flask filled with distilled water at one end of the quartz tube, heat and boil the distilled water, and treat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com