Nitrogen/transition metal-codoped hierarchical-pore carbon oxygen reduction catalyst, and preparation method and application thereof

A technology of transition metals and transition metal salts, which is applied in the direction of fuel cell half-cells and primary battery half-cells, electrical components, battery electrodes, etc., to achieve the effects of overcoming corrosion problems, high yields, and increased yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A nitrogen / M (M=Fe / Co / Ni) co-doped hierarchical porous carbon catalyst is obtained by processing the precursor, and the precursor includes silicon dioxide powder with a mass content of 20%, a mass content of It is 25% nitrogen-containing high polymer [polyquaternized (bis(2-chloroethyl) ether-alt-1,3-bis[3-(dimethylamino)propyl]urea (abbreviation: PQ-2 , Sigmaaldrich company) and a metal salt (FeSO 4 , CoSO 4 , NiSO 4 ). The above mass content is based on the total mass of the precursor. The treatment includes the first roasting reduction treatment, alkali washing treatment, pickling treatment and the second roasting reduction treatment.

[0046] The preparation method of the nitrogen / M co-doped hierarchical porous carbon-oxygen reduction catalyst is:

[0047] (1) PQ-2, particle diameter is that 500nm silicon dioxide powder and transition metal salt are configured into respectively the PQ-2 solution of 5%, the SiO of 10% with the hydrochloric acid of 1 mole per lit...

Embodiment 2

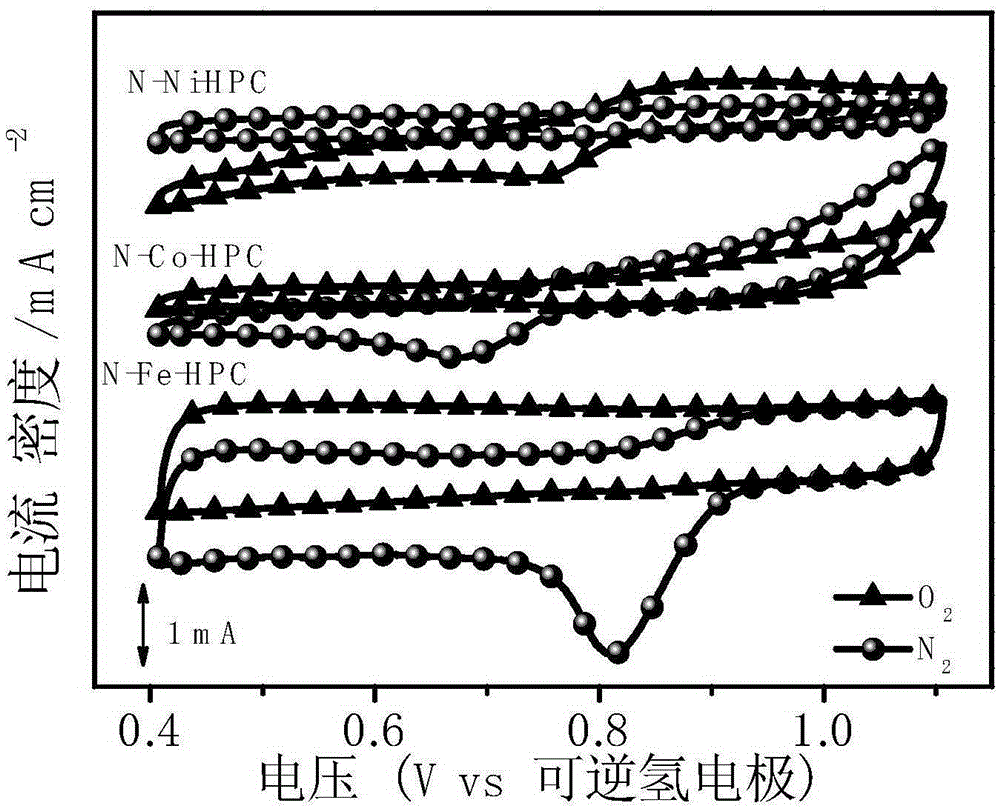

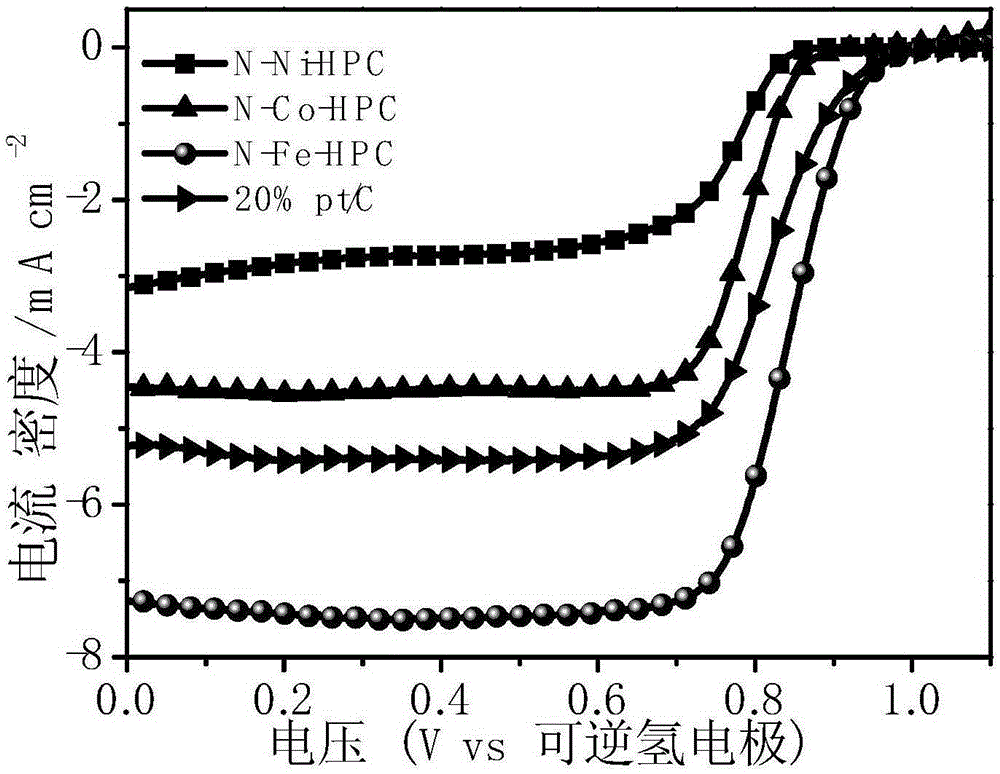

[0054] The Nafion solution that isopropanol and mass concentration is 0.5% is mixed according to the volume ratio 4:1, obtains the mixed solution of isopropanol and Nafion, the nitrogen / M co-doped hierarchical porous carbon catalyst obtained in the embodiment 1 of 2mg and 20% The Pt / C catalyst was dispersed into the mixed solution of 0.6 ml of isopropanol and Nafion, and a homogeneous catalyst solution was obtained under the action of ultrasound. Then it was drop-coated on the glass disk electrode, so that the loading of catalysts N-Fe-HPC, N-Ni-HPC, and N-Co-HPC was 500 μg / cm 2 , the loading of 20% Pt / C catalyst is 100 μg / cm 2 , to dry naturally. Oxygen was introduced into the electrolyte solution for 30 minutes, and then the glassy carbon disk electrode coated with the catalyst was used as the working electrode, and the saturated calomel electrode and the Pt electrode were respectively used as the reference electrode and the counter electrode, and N-Fe- Polarization curves...

Embodiment 3

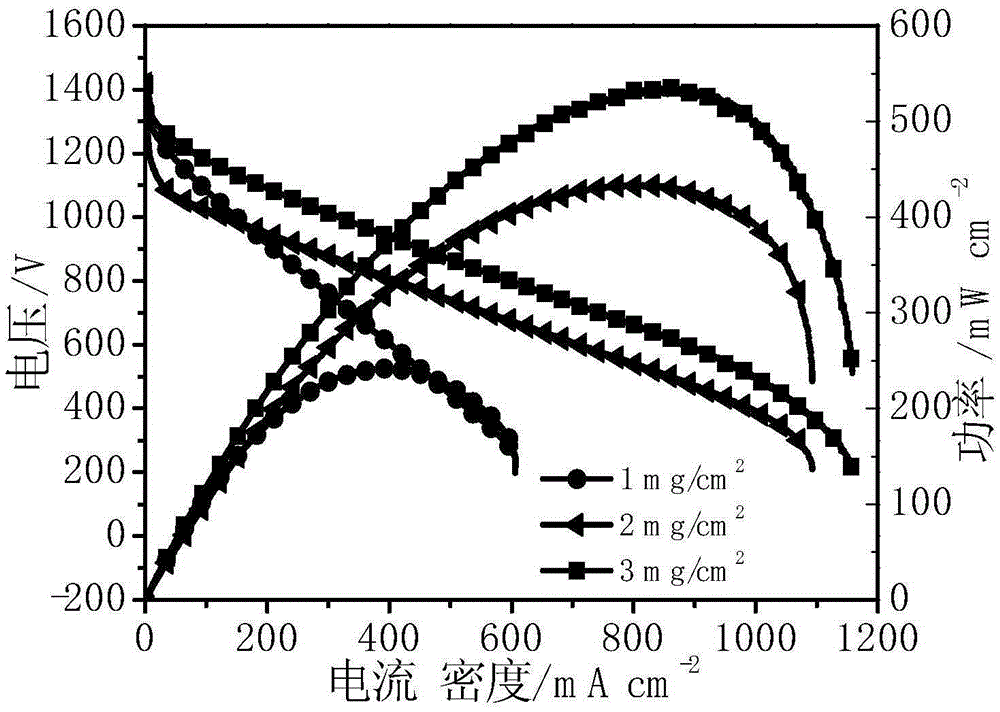

[0057] Mix isopropanol and a Nafion solution with a mass concentration of 0.5% according to a volume ratio of 3:1 to obtain a mixed solution of isopropanol and Nafion, and disperse 10 mg of the N-Fe-HPC catalyst obtained in Example 1 into the above-mentioned 12 ml of isopropanol and Nafion In the mixed solution, a homogeneous catalyst solution was obtained under the action of ultrasound. Then spray on the hydrophobic treated carbon paper (loading 1.0, 2.0, 3.0mg / cm 2 ), dried at 60°C for 30 minutes to prepare the air electrode, and at the same time, the zinc foil with the same area as the carbon paper was used as the negative electrode, and the air electrode and the zinc foil were put into the 6mol / L potassium hydroxide solution to form the actual two Electrode zinc-air battery, using the fuel cell activation system to test using the gradual current mode: normal temperature and pressure, test the power generation curve and polarization curve.

[0058] Such as image 3 As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Electric current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com