Metal-free nitrogen- functionalized carbon catalyst as well as preparation method and application thereof

A technology of carbon catalyst and nitrogen doping, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. And stability gap, not suitable for industrial production and other problems, to achieve good application prospects, improve catalytic activity, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

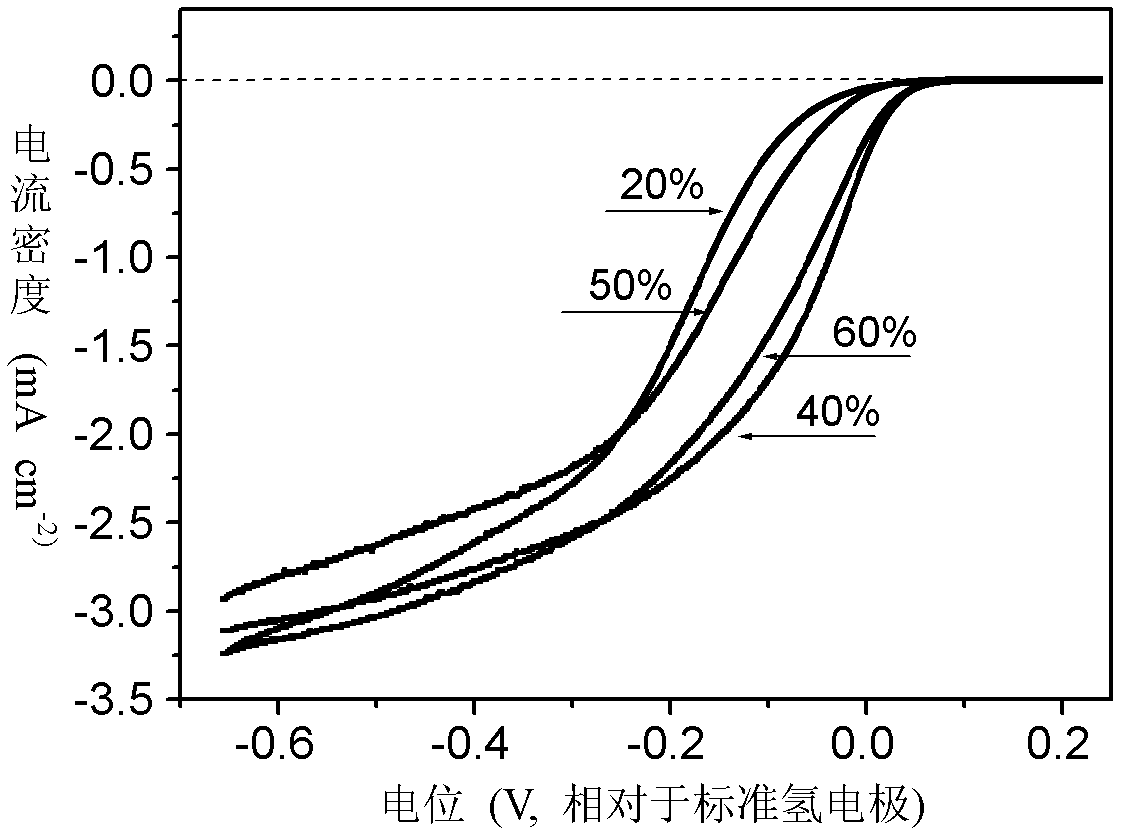

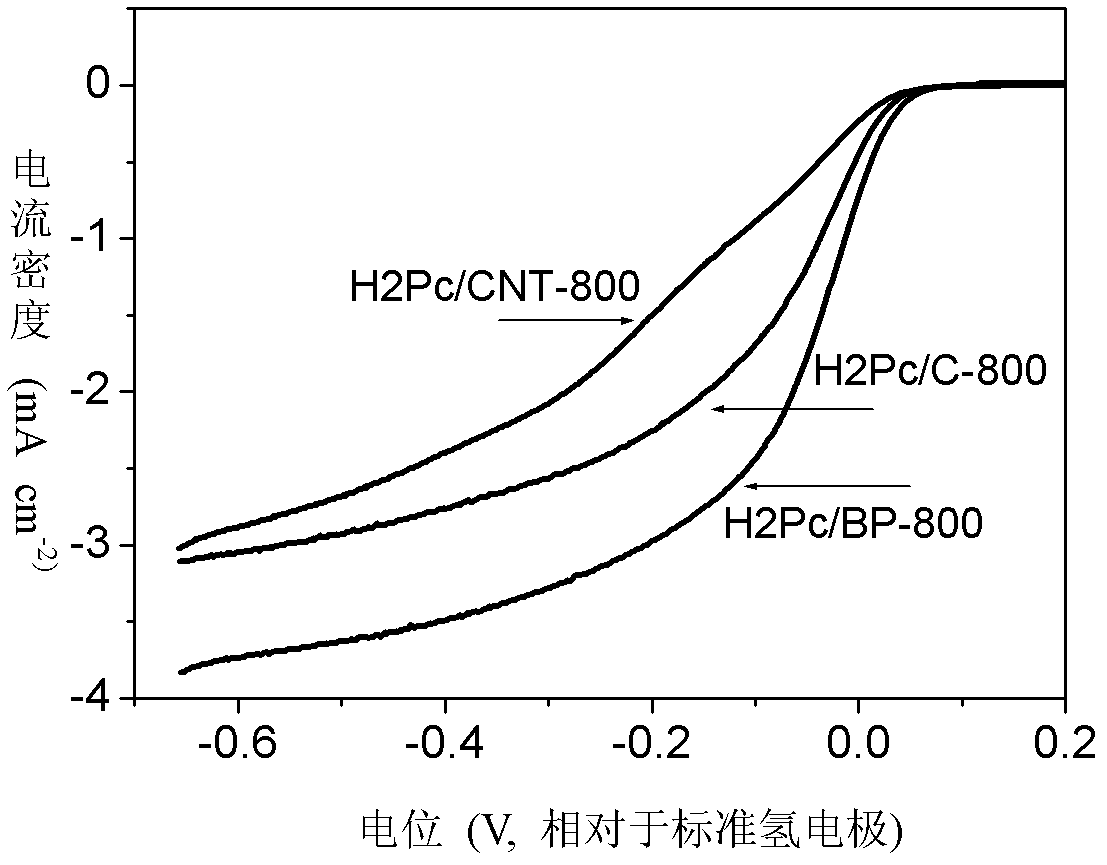

[0026] Weigh 0.0400g phthalocyanine and 0.0600g Vulcan XC-72R carbon powder and place them in an agate mortar. Then add 10ml of methanol of analytical grade and grind thoroughly until the methanol is completely volatilized. Put the agate mortar and the mixture inside into a vacuum oven at 40°C for 1 hour to obtain the desired 40% H 2 Pc / C catalyst precursor. Place the dried mixture in the agate mortar in a quartz boat under N 2 Under the protection of the atmosphere, the heating rate was raised to 1000°C at a rate of 10°C / min and the reduction treatment was carried out for 3 hours to obtain the required 40%H 2 Pc / C catalyst.

Embodiment 2

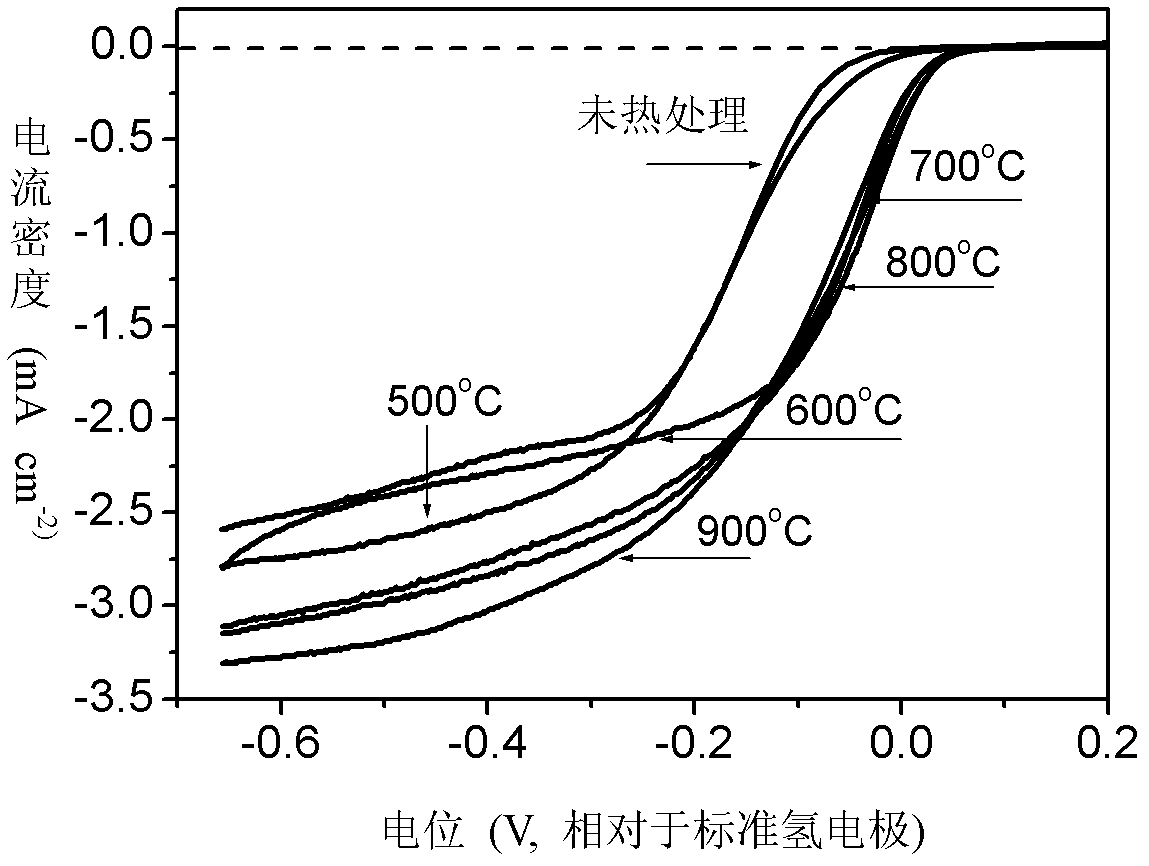

[0028] Weigh 0.0040g phthalocyanine and 0.0600g Vulcan XC-72R carbon powder and place them in an agate mortar. Then add 10ml of methanol of analytical grade and grind thoroughly until the methanol is completely volatilized. Put the agate mortar and the mixture inside into a vacuum oven at 40°C for 1 hour to obtain the desired 40% H 2 Pc / C catalyst precursor. Place the dried mixture in the agate mortar in a quartz boat under N 2 Under the protection of the atmosphere, the heating rate was raised to 600°C at a rate of 10°C / min and the reduction treatment was carried out for 2 hours to obtain the required 40%H 2 Pc / C-600 catalyst.

Embodiment 3

[0030] Weigh 0.0040g phthalocyanine and 0.0600g Vulcan XC-72R carbon powder and place them in an agate mortar. Then add 2ml of methanol of analytical grade, fully grind until the methanol is completely volatilized, repeat this step 5 times, the total amount of methanol is 10ml. Put the agate mortar and the mixture inside into a vacuum oven at 40°C for 1 hour to obtain the desired 40% H 2 Pc / C-600 catalyst precursor. Place the dried mixture in the agate mortar in a quartz boat under N 2 Under the protection of the atmosphere, the heating rate was raised to 700°C at a rate of 20°C / min and the reduction treatment was carried out for 3 hours to obtain the required 40%H 2 Pc / C-700 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com