Device and method for processing municipal utilities foul gas

A malodorous gas and facility technology, which is applied in the field of malodorous gas devices, can solve the problems of short gas reaction time, underutilization, secondary pollution, etc., and achieves short reaction time, high deodorization and waste removal efficiency, and waste gas treatment volume. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

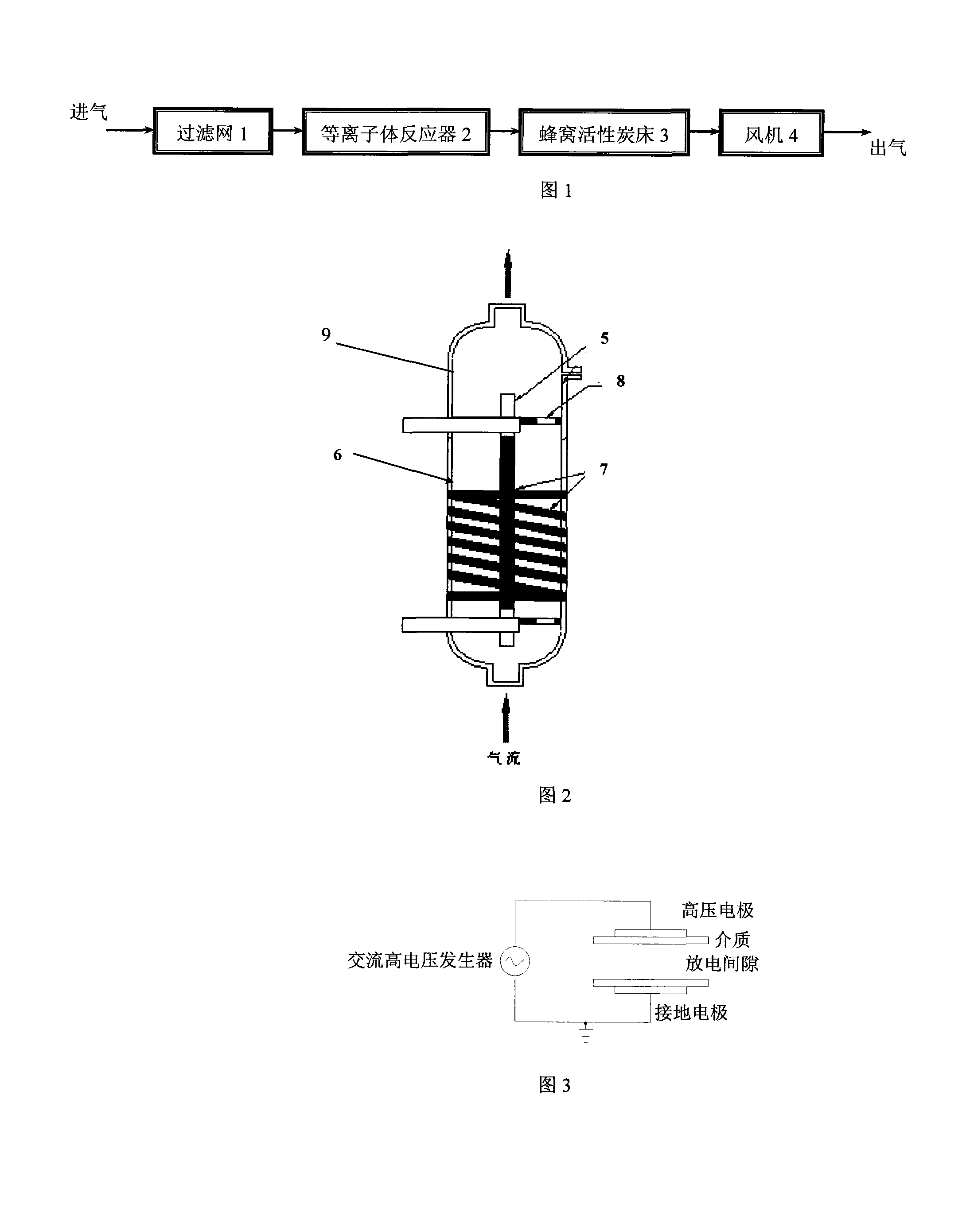

[0024] With a gas volume of 10000m 3 / h, the concentration of 100ppm malodorous gas as an example to illustrate the parameters of each process unit:

[0025] ①. Filter: 100 mesh

[0026] ②. Plasma reactor: The number of plasma reaction tubes is 250 groups, and the installed power is 55kW. Each plasma reaction tube uses two quartz tubes inside and outside as the medium. The inner tube has an outer diameter of 10mm and a length of 200mm, and is lined with a 200mm stainless steel sheet as the inner electrode; the outer tube has an inner diameter of 33mm, a thickness of 1.5mm, and a length of 200mm. A slender stainless steel sheet is wound around the outer tube wall 6 times as the outer electrode, and the distance between the rings is 5 mm.

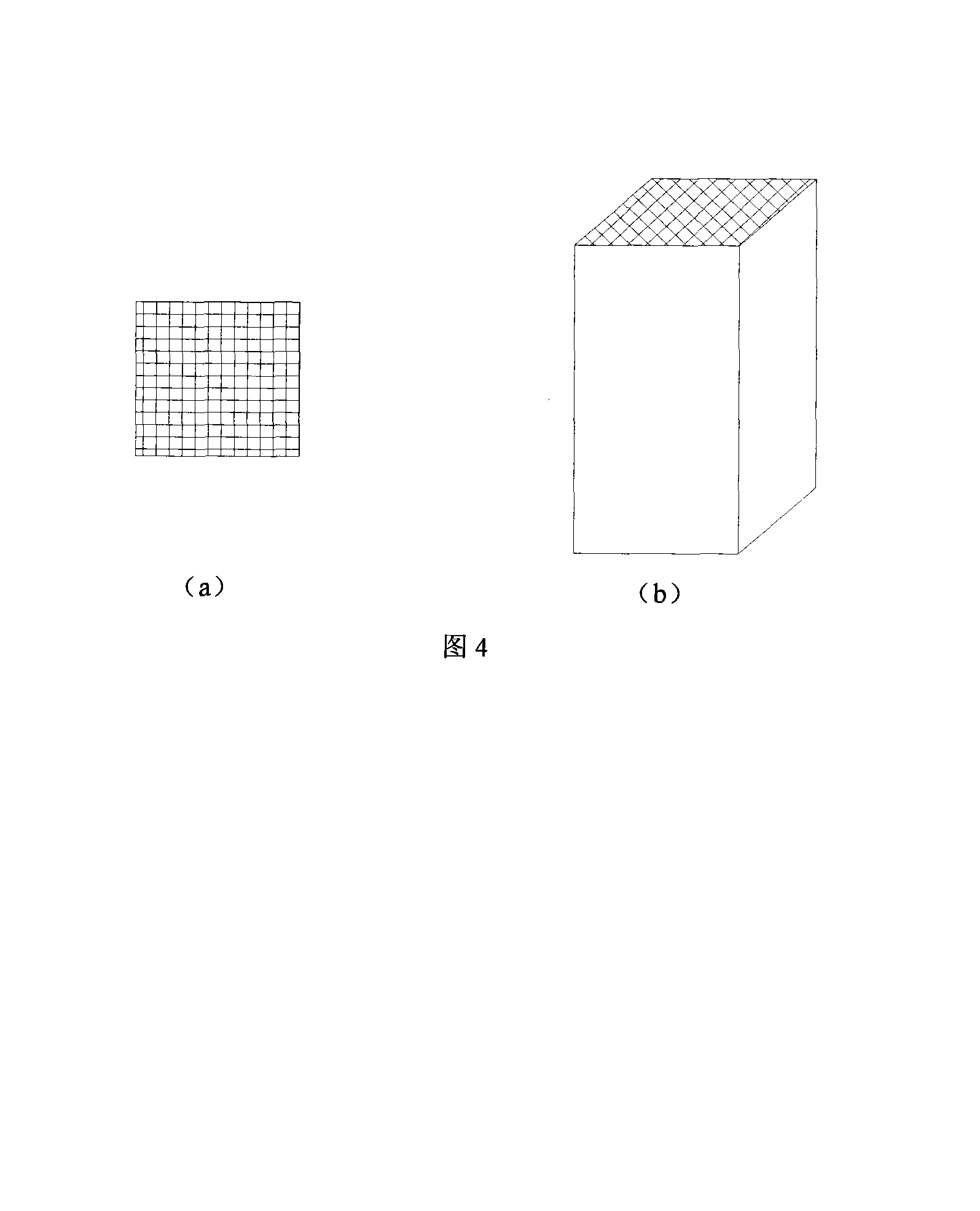

[0027] ③.Honeycomb activated carbon bed: single group length 2000mm×width 2000mm×height 1500mm, 2 groups in total, with a total honeycomb activated carbon loading capacity of 8m 3 .

[0028] ④. Fan: matching power 11kW.

[0029] It can h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com