Flue gas adsorbing and purifying device for coke oven

A purification device and flue gas technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve problems such as unfavorable layout, reduced work efficiency, large occupation, etc., to reduce purchase costs and operating costs, improve Effective filtration area and the effect of treating a large amount of exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

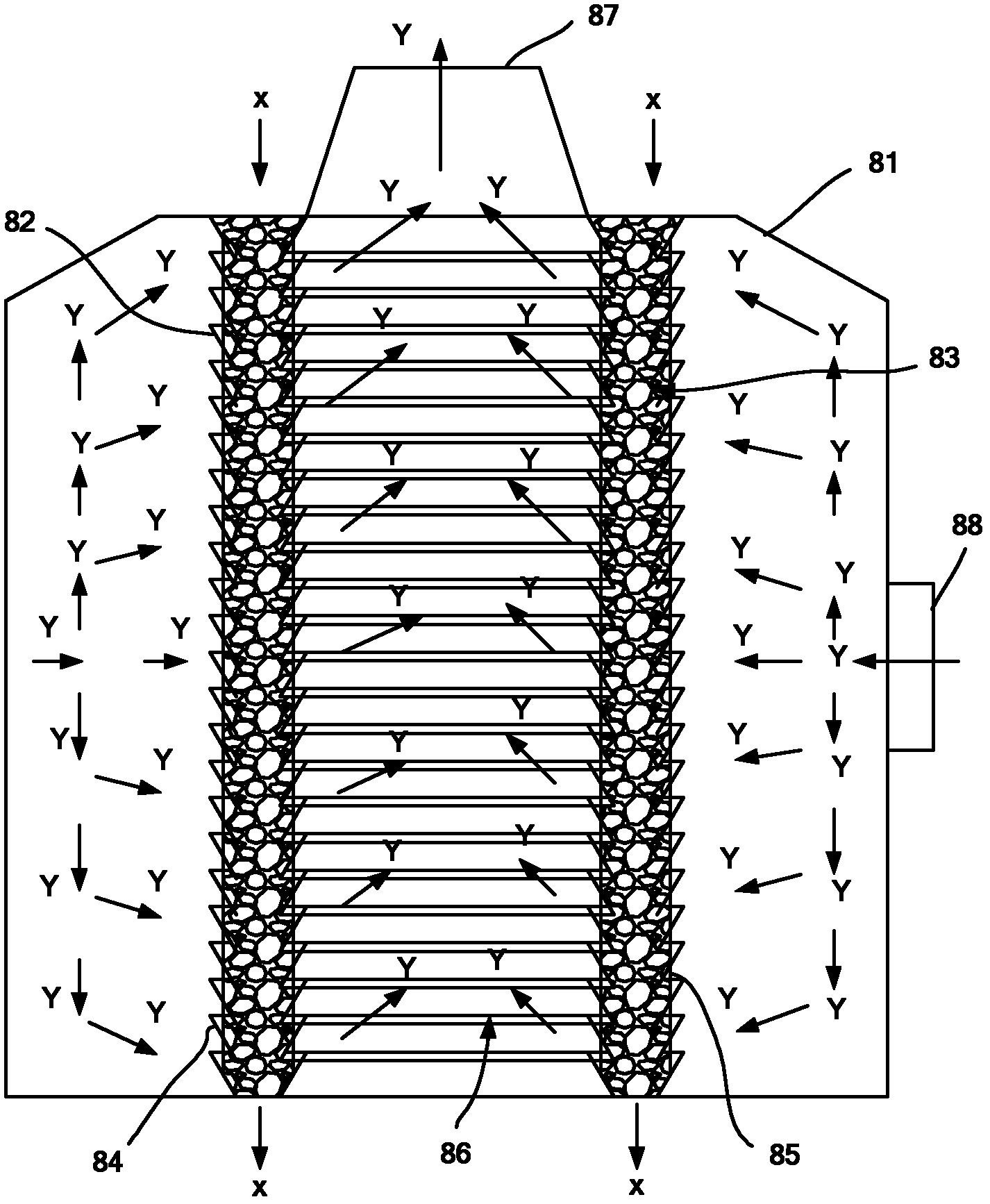

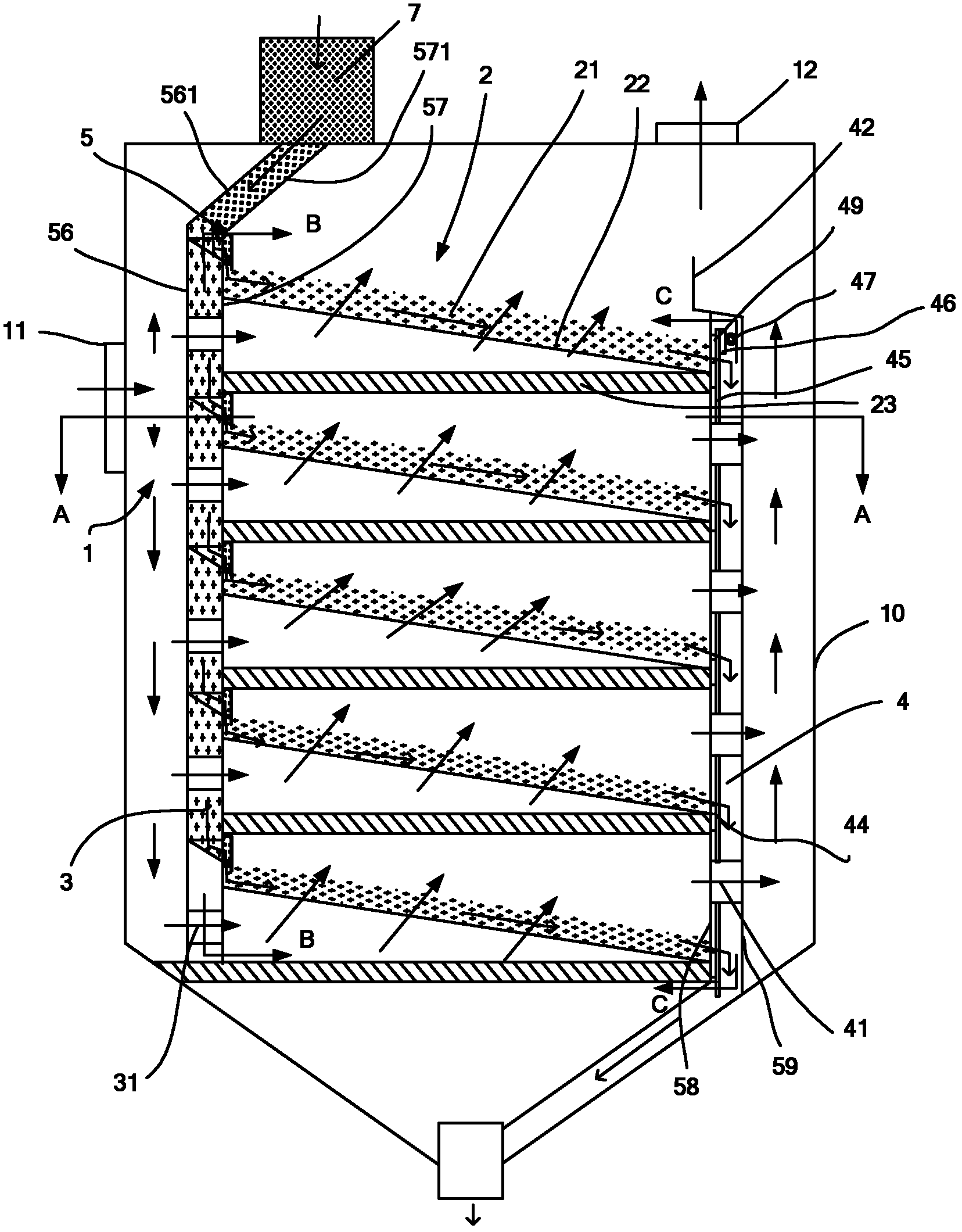

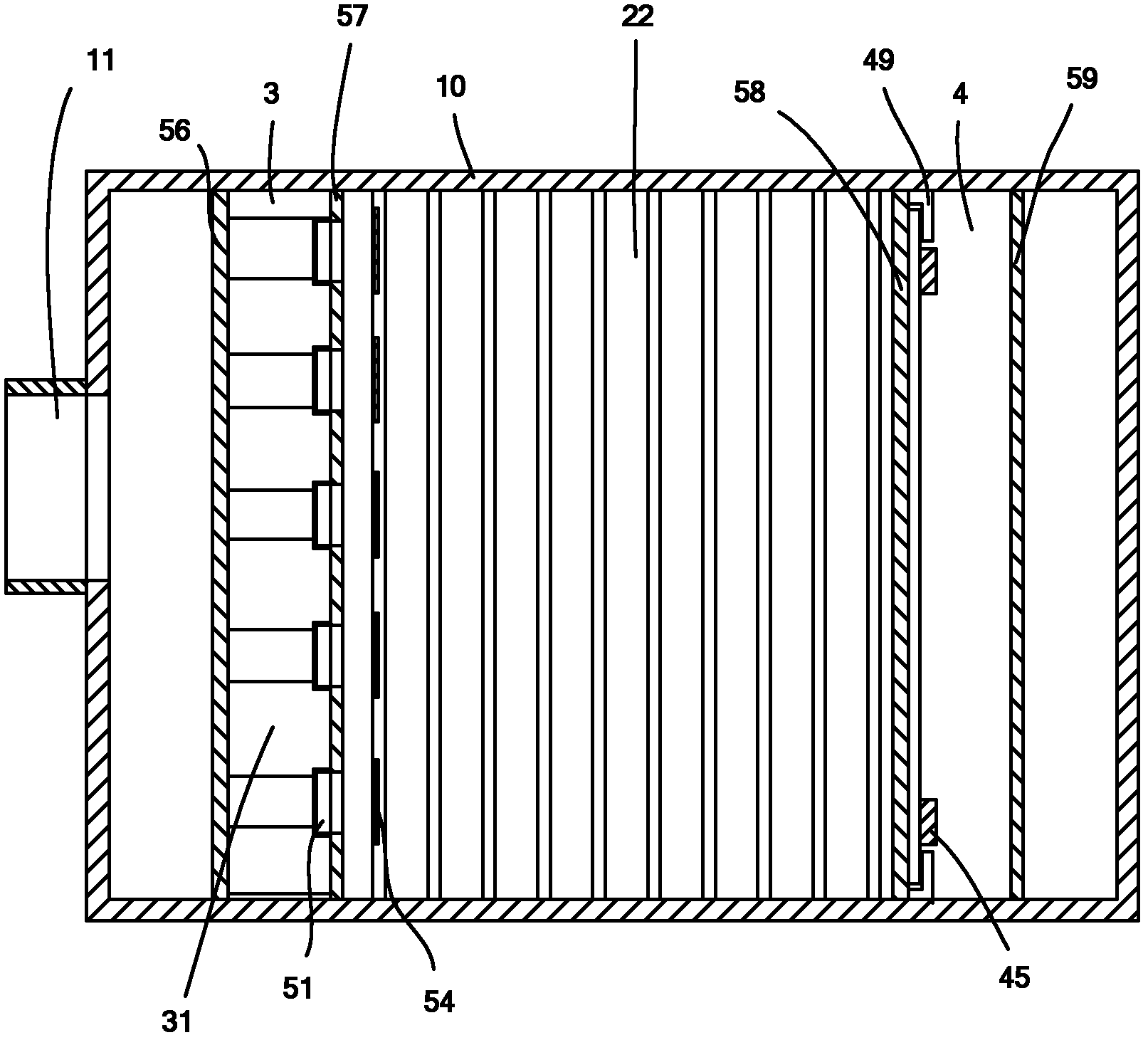

[0033] Such as figure 2 and image 3 As shown, the direction shown by the solid arrow in the figure is the gas flow direction, and the direction shown by the hollow arrow is the conveying direction of the filter material. The embodiment of the present invention includes a cylindrical body 10, the upper part of which is a cuboid, and the lower part is a cone, and the cylindrical body 10 is fixedly arranged. The cylinder body 10 includes an air duct 1 and five independent filter units 2 . The air duct 1 is arranged in the cylinder body 10, the air inlet 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com