Production process of silk fiber spunlace non-woven fabrics

A technology of spunlace non-woven fabrics and silk fibers, which is applied in non-woven fabrics, textiles and papermaking, and spray/jet textile material processing, etc. It can solve problems such as hard hand feeling, rough surface of hot-air non-woven fabrics, and poor comfort. Achieve the effect of soft hand feeling, smooth surface and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

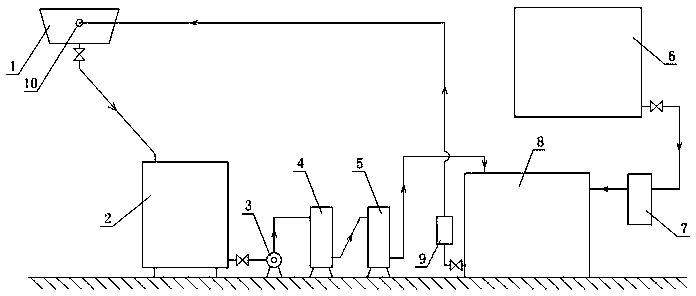

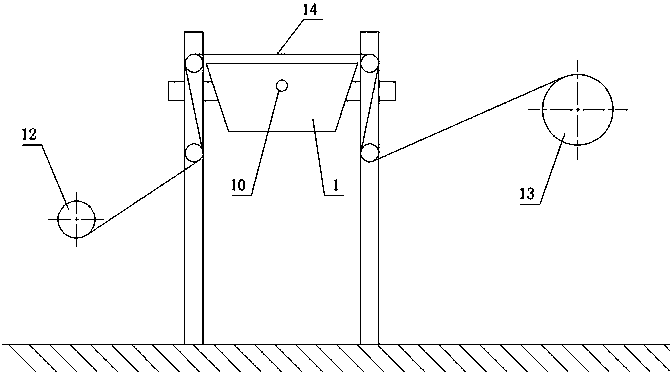

[0022] The production process of the silk fiber spunlace nonwoven fabric of the present invention adopts 50% (weight percentage) of silk fiber and 50% (weight percentage) of tencel fiber as raw materials, and sequentially enters the opening process, carding process, spunlace process, pro- Water treatment process, drying process, online detection process, coiling process, slitting process.

[0023] Among them, the cotton feeding box in the carding process adopts two-way feeding air flow to vibrate the cotton box.

[0024] The feeding curtain in the carding process uses a weighing curtain to weigh and feed the cotton.

[0025] The carding process uses a high-speed messy carding machine to card into a web.

[0026] The working roll of the main cylinder in the carding process is 100-120m / min, the stripping roll of the main cylinder is 130-140m / min, the rotation speed of the main cylinder is 700-800 m / min, and the feeding weight is 45 grams / ㎡.

[0027] In the spunlace process, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com