Process for atomizing desulfurization waste water through recycled flue gas of tower type boiler

A technology for desulfurization wastewater and tower boilers, which is applied in gas treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of slow evaporation rate of desulfurization wastewater, corrosion of electrode plates of dust collectors, and high suspended solids content. The effect of harmless treatment, avoiding equipment corrosion and increasing initial temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

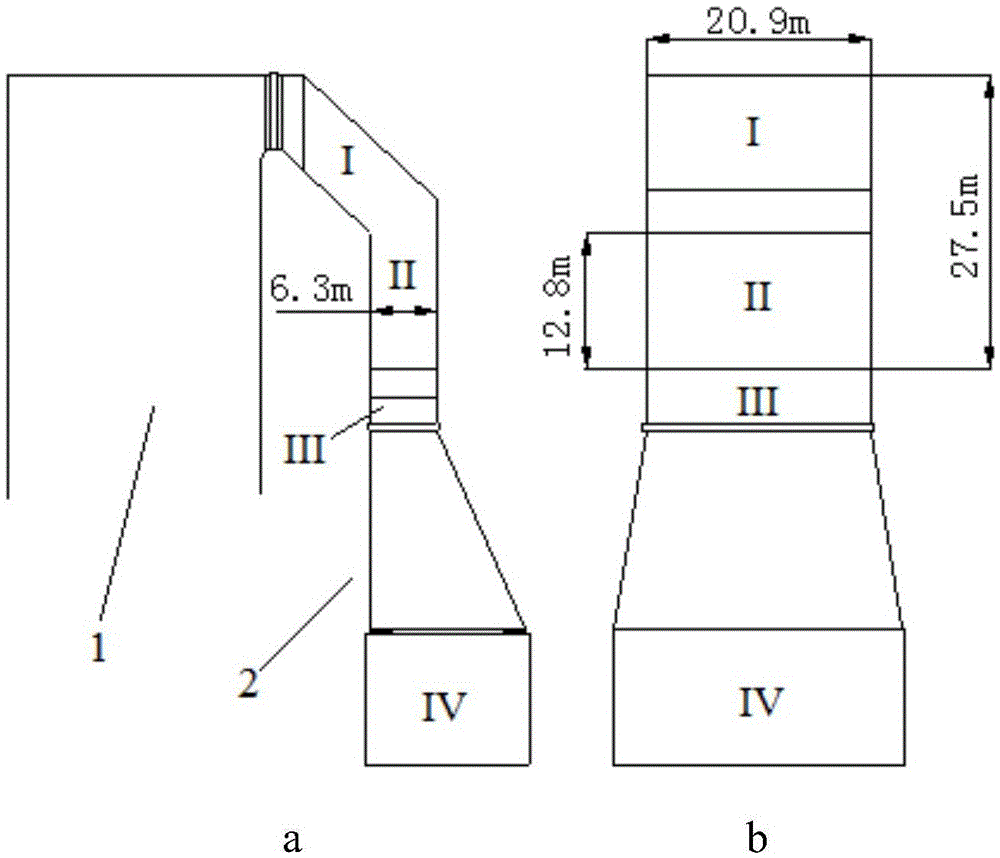

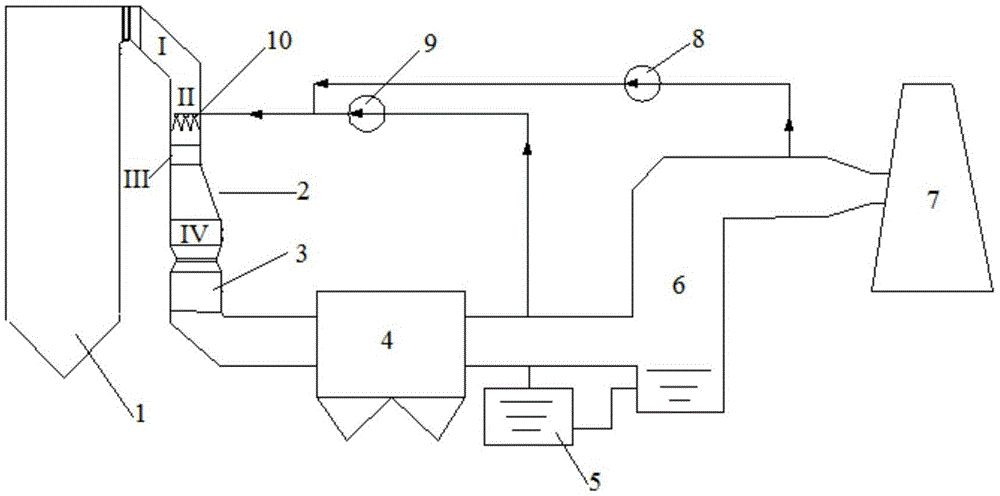

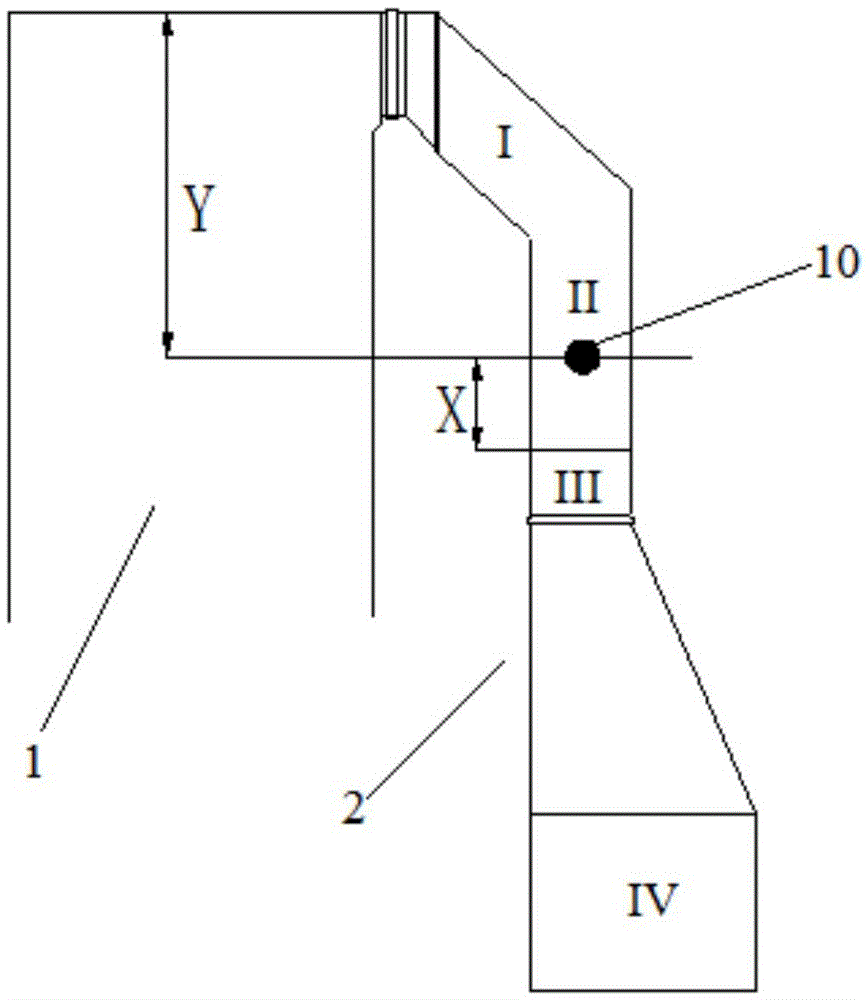

[0038] At present, the types of large-capacity boilers in the world mainly include tower boilers and π-type furnaces. Tower boilers mainly adopt a single furnace and single flue arrangement. Taking the tower boiler 1 of a 1000MW unit as an example, figure 1 a-b is the structural diagram of the tail flue of the tower boiler. In the tail flue, the vertical flue II is between the inclined flue I and the SCR ammonia injection area III. The length of the vertical flue II is 12.8m, and the cross-sectional area is 6.3m*20.9m. The temperature is 300-400°C, and the flue gas velocity is 6-10m / s. The vertical flue II at the tail of the tower boiler 1 has a larger pipeline space and a higher flue gas temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com