Nano titanium oxide inorganic surface treatment method

A nano-titanium dioxide, surface treatment technology, applied in inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., to achieve the effect of reducing agglomeration, avoiding flocculation, and good light stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

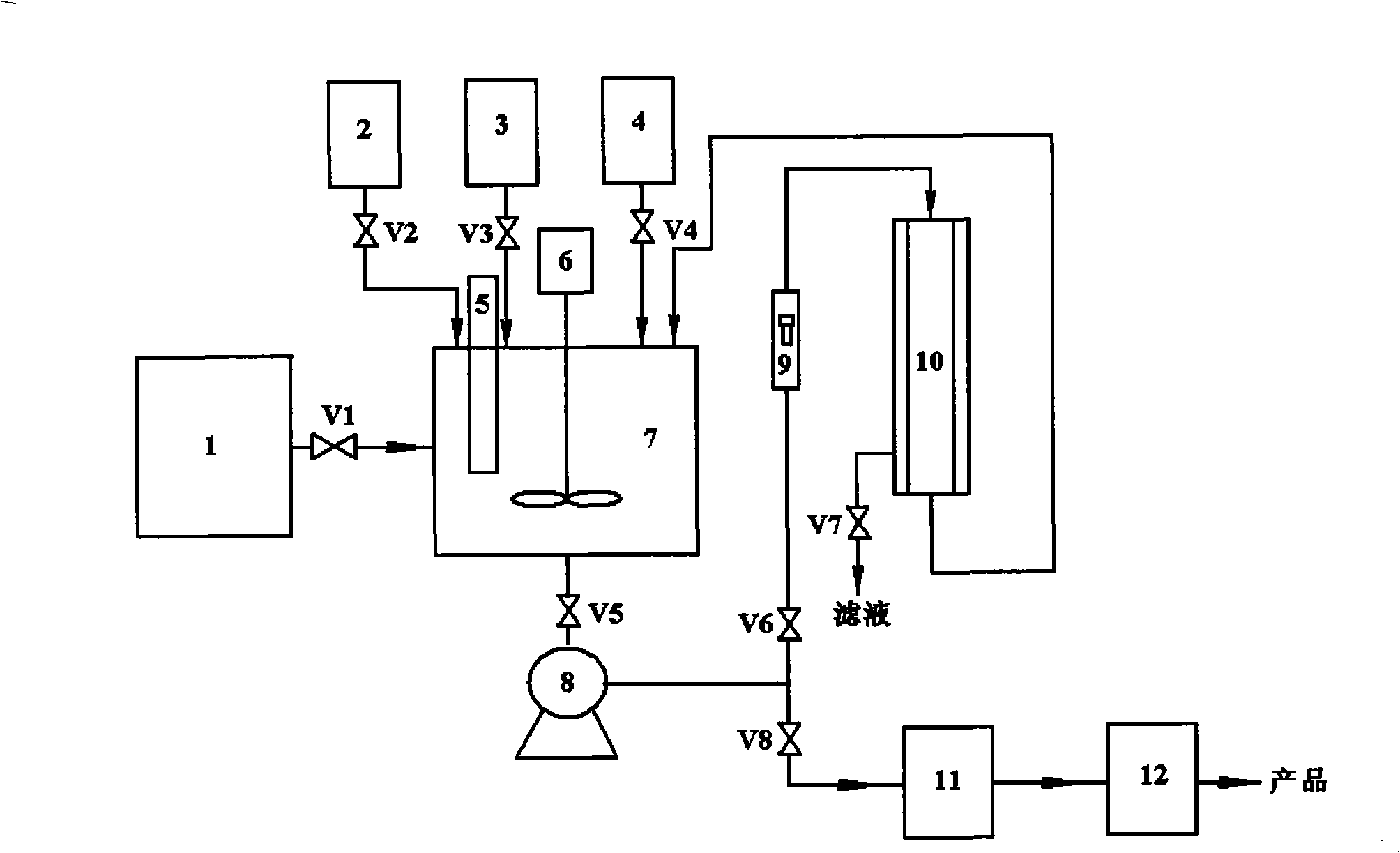

Method used

Image

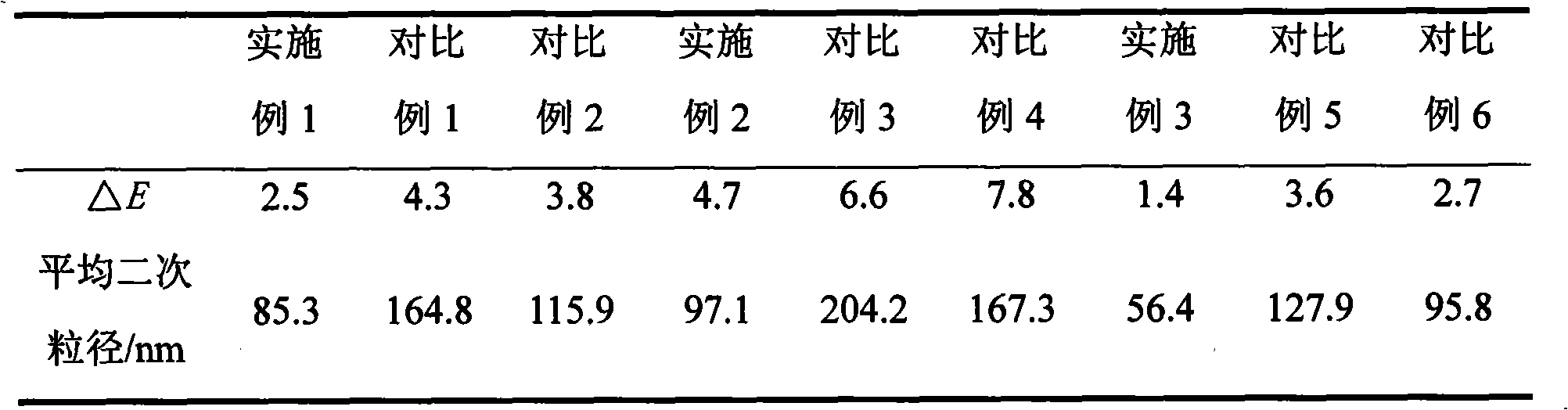

Examples

Embodiment 1

[0022]Add 0.4 kilogram of sodium hexametaphosphate to 210 kilograms of deionized water as dispersant, after sodium hexametaphosphate dissolves, add 80 kilograms of rutile nano-titanium dioxide (average particle diameter 30 nanometers) again, be mixed with nano-titanium dioxide slurry, use hydrogen Aqueous sodium oxide solution was used to adjust the pH value of the slurry to 9.5. Put the obtained nano-titanium dioxide slurry in dispersion device 1 (PM-PMC270 sand mill), use zirconia balls with a diameter of 0.8-1.0mm as the grinding medium, grind and disperse for 120min, and obtain a nano-titanium dioxide aqueous dispersion. The nano-titanium dioxide aqueous dispersion enters the 2000-liter inorganic surface treatment reactor 7 through the control valve V1, adds deionized water, and dilutes to a solid content of 12%. Turn on the mechanical stirring device 6 and the ultrasonic dispersing device 5 to keep the nano titanium dioxide in the reactor in a good dispersion state. Turn...

Embodiment 2

[0024] Add 0.6 kilogram of sodium hexametaphosphate to 210 kilograms of deionized water as dispersant, after sodium hexametaphosphate dissolves, add 60 kilograms of anatase type nano-titanium dioxide (average particle diameter 10 nanometers) again, be mixed with nano-titanium dioxide slurry, The pH of the slurry was adjusted to 9.0 with aqueous sodium hydroxide solution. Put the obtained nano-titanium dioxide slurry in dispersion device 1 (PM-PMC270 sand mill), use zirconia balls with a diameter of 0.8-1.0mm as the grinding medium, grind and disperse for 120min, and obtain a nano-titanium dioxide aqueous dispersion. The nano-titanium dioxide aqueous dispersion enters the 2000-liter inorganic surface treatment reactor 7 through the control valve V1, adds deionized water, and dilutes to a solid content of 4%. Turn on the mechanical stirring device 6 and the ultrasonic dispersing device 5 to keep the nano titanium dioxide in the reactor in a good dispersion state. Turn on the he...

Embodiment 3

[0026] Add 0.72 kilogram of sodium hexametaphosphate to 210 kilograms of deionized water as dispersant, after sodium hexametaphosphate dissolves, add 72 kilograms of rutile nano-titanium dioxide (average particle diameter 15 nanometers) again, be mixed with nano-titanium dioxide slurry, use hydrogen An aqueous solution of sodium oxide was used to adjust the pH of the slurry to 9.0. Put the obtained nano-titanium dioxide slurry in dispersion device 1 (PM-PMC270 sand mill), use zirconia balls with a diameter of 0.8-1.0mm as the grinding medium, grind and disperse for 120min, and obtain a nano-titanium dioxide aqueous dispersion. The nano-titanium dioxide aqueous dispersion enters the 2000-liter inorganic surface treatment reactor 7 through the control valve V1, adds deionized water, and dilutes to a solid content of 6%. Turn on the mechanical stirring device 6 and the ultrasonic dispersing device 5 to keep the nano titanium dioxide in the reactor in a good dispersion state. Tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com