High-pressure mixed gas generator used for petroleum thermal recovery gas injection machine

A high-pressure mixing and gas generation technology, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of poor cooling water flow, shortened burner service life, complicated structure, etc. The effect of working cycle, improving combustion reaction speed and improving working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

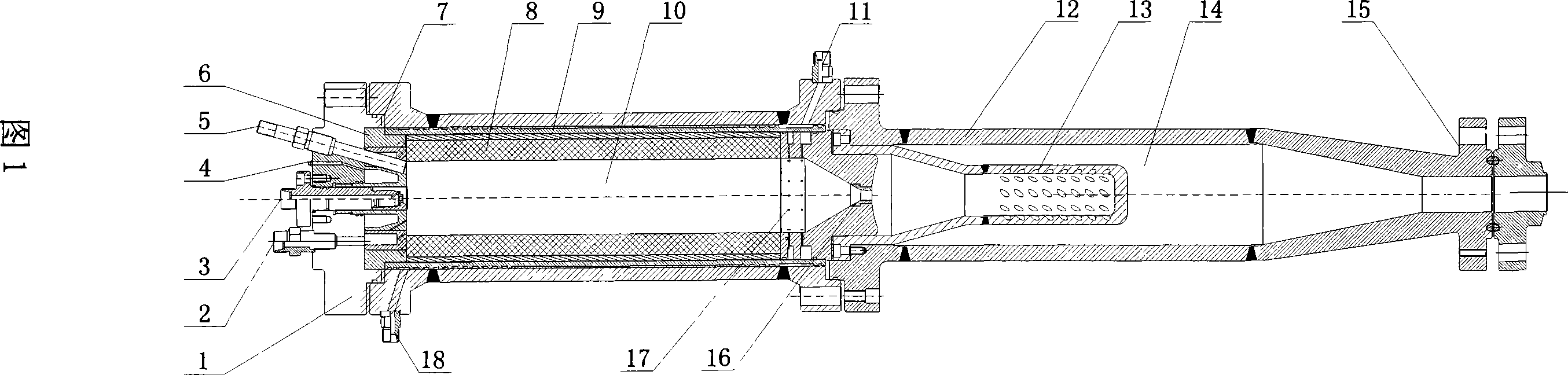

[0024] Embodiment: As shown in Fig. 1, a high-pressure mixed gas generating device is composed of a head 1, a combustion section 7, and a mixing section 12 to form an integral device.

[0025] Diesel oil enters the combustion chamber 10 from the oil nozzle 3 , compressed air enters the combustion chamber 10 from the air distributor 2 , and the working end of the igniter 5 also leads to the combustion chamber 10 .

[0026] A stream of cooling water goes deep into the spiral annular cooling chamber close to the end of the cooling water cap 4 from the interface of the cooling water cap 4, then is discharged from the outlet joint, and then connected to the inlet joint 11 of the thermostat through an external water pipe, and then passed through The second group of spray holes (rear end) of the thermostat 17 leads into the thermostat.

[0027] Another strand of cooling water enters the cooling water jacket 9 from the inlet joint 18, and passes into the thermostat 17 through the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com