Environment-protecting synergistic agent for fuel coal

A synergistic and environmentally friendly technology, applied in the direction of fuel additives, fuels, solid fuels, etc., can solve the problems of reducing the heat absorption capacity of the boiler, coking, and reducing the effective combustion rate of coal combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

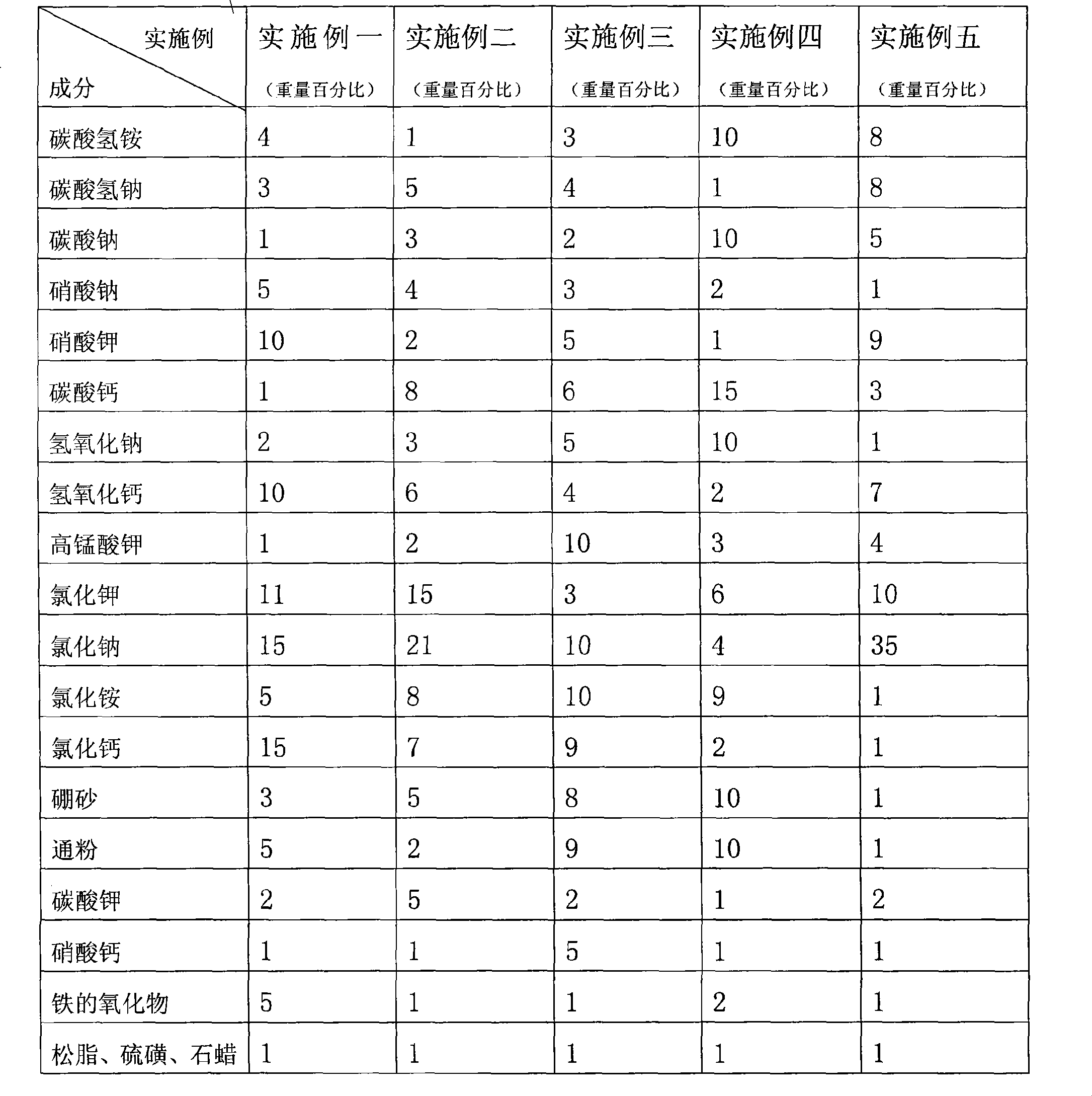

Examples

Embodiment approach 1

[0026] Take the following ingredients (weight unit kilogram):

[0027] Ammonium bicarbonate 8

[0028] Sodium bicarbonate 8

[0031] Potassium nitrate 9

[0032] calcium carbonate 3

[0033] sodium hydroxide 1

[0034] calcium hydroxide 7

[0035] Potassium permanganate 4

[0036] Potassium chloride 10

[0037] Sodium chloride 35

[0038] Ammonium chloride 1

[0039] Calcium chloride 1

[0040] Borax 1

[0041] macaroni 1

[0042] Potassium Carbonate 2

[0043] Calcium nitrate 1

[0044] Iron Oxide 1

[0045] The balance is a total of 1 of the trace components turpentine, sulfur and paraffin.

[0046] The above ingredients are pulverized and then mixed, the mixing uniformity is required to be above 60%, the higher the better, the product of the present invention is obtained, the product is gray or gray black powder, non-toxic, non-radiative, difficult to burn, weakly alkaline, with Ammonia.

[0047] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com