Bolt assembling automatic production robot and assembling method thereof

A technology of robots and bolts, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as time-consuming, unfavorable assembly efficiency, and insufficient automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

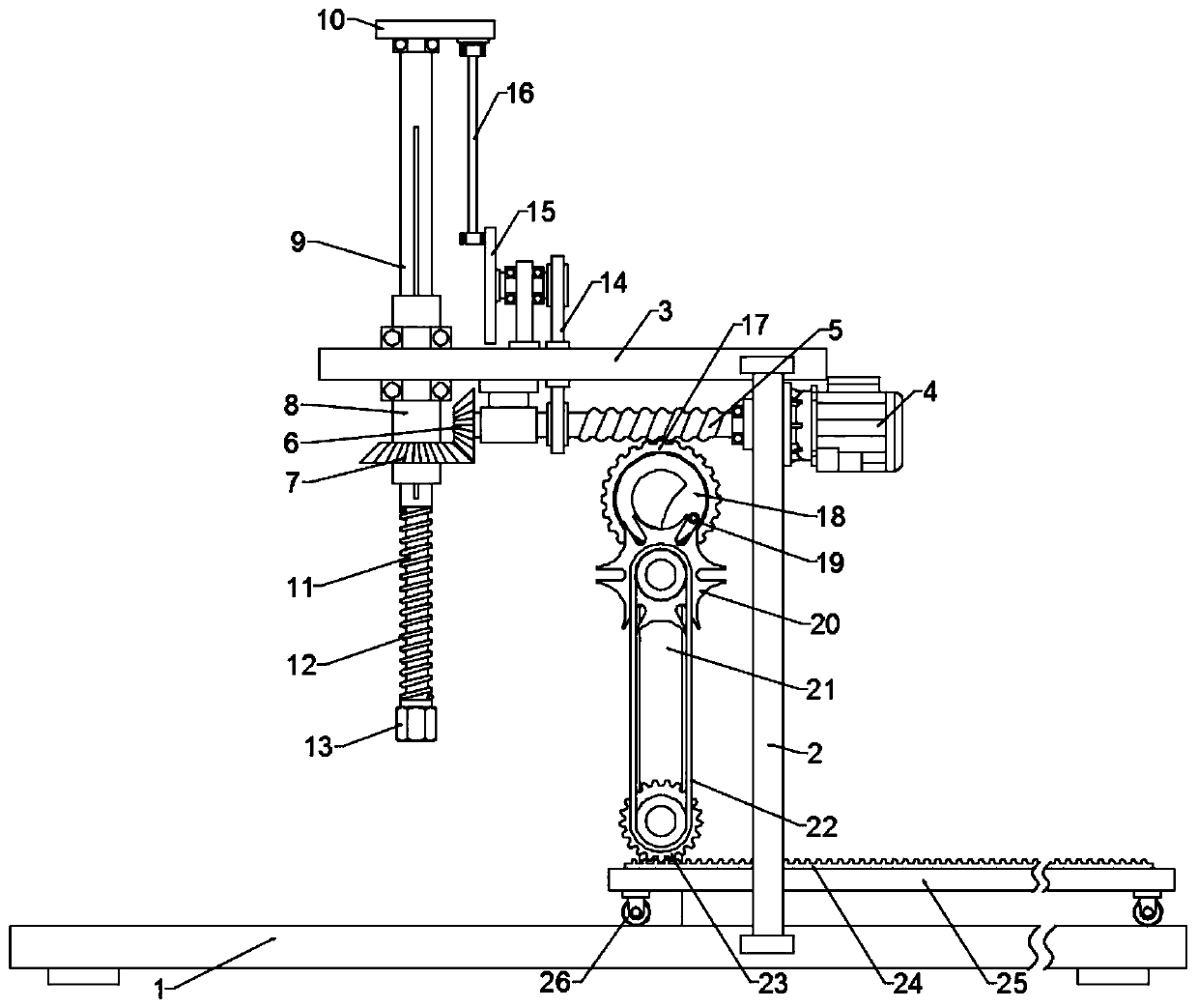

[0030] see Figure 1~4 , in an embodiment of the present invention, a robot for automatic production of bolt assembly includes a workbench 1, a side column 2 whose lower end is fixedly installed on the front side wall of the workbench 1, a top plate 3 fixed on the upper end of the side column 2, and a flange installed on the The upper part of the side column 2 is electrically connected to the electric motor 4 of the power supply and the switch, the worm 5 connected to the output end of the electric motor 4, the locking mechanism and the moving mechanism connected to the worm 5;

[0031] Specifically, the worm 5 passes through the side column 2 and is bearing-connected with it. The side of the worm 5 away from the electric motor 4 is sleeved on a sleeve fixed to the lower part of the top plate 3, and the electric motor 4 is powered on by starting the switch. Drive its work, and electric motor 4 work drives worm screw 5 to rotate.

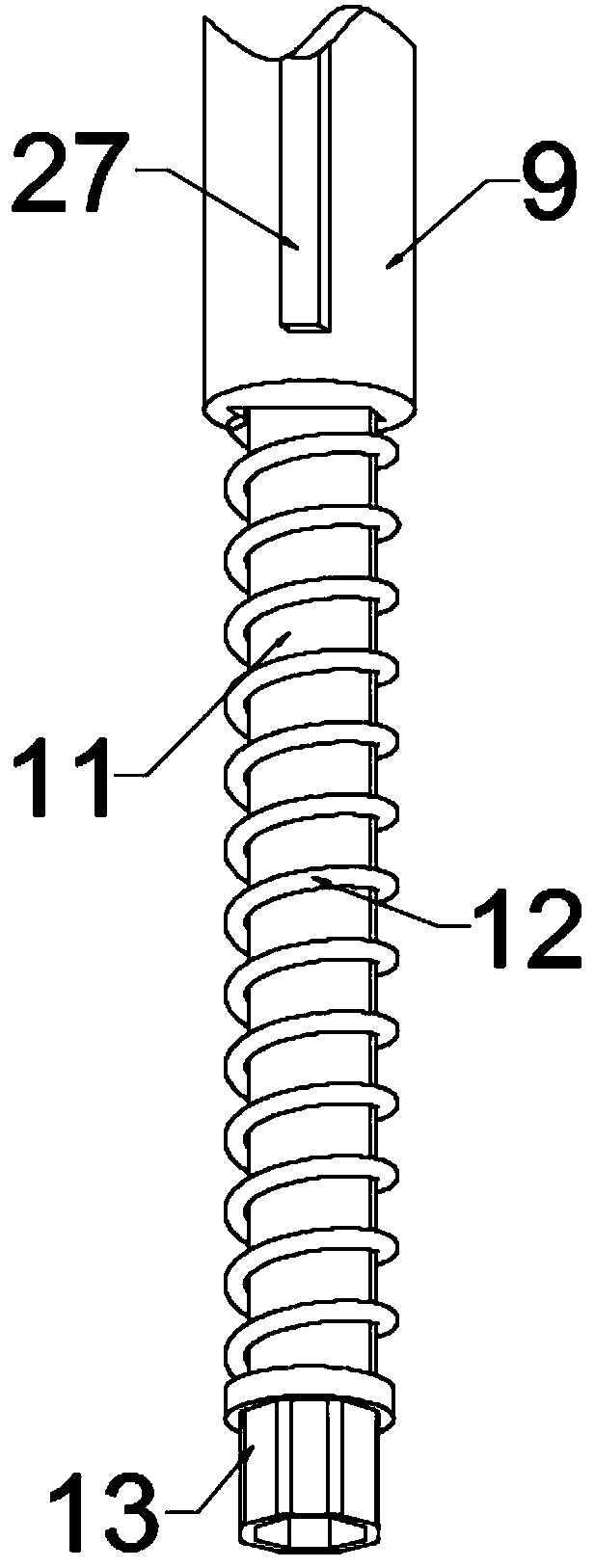

[0032] Further, the locking mechanism include...

Embodiment 2

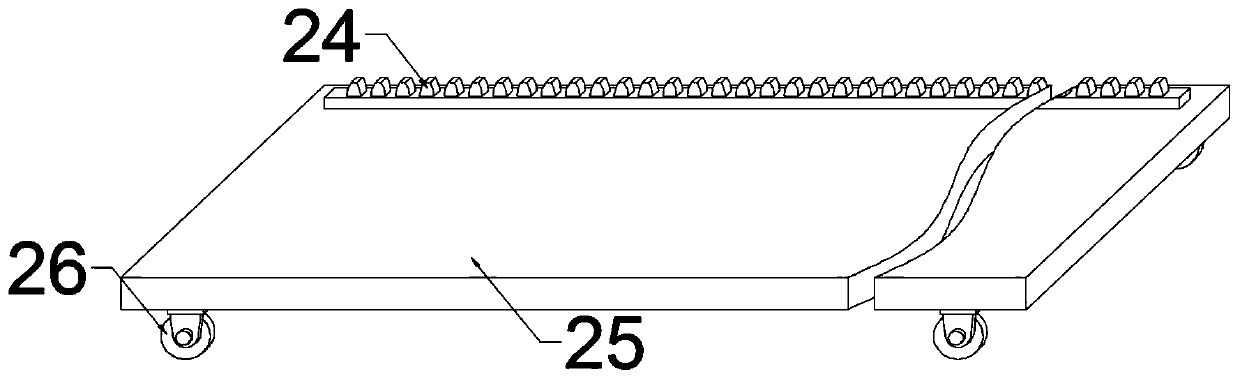

[0037] In order to achieve the continuous work function of automatic shifting of the workpiece and matching the hexagonal lock sleeve 13, in another embodiment of the present invention, a robot for automatic production of bolt assembly also includes a feeding mechanism, and the feeding mechanism includes a worm gear engaging the worm 5 17. The Maltese cross movement assembly connected with the worm gear 17, the gear 23 connected to the Maltese cross movement assembly, the rack 24 meshed with the gear 23 and fixed on the supporting plate 25, wherein the worm gear 17, the Maltese cross movement assembly and The gears 23 are all rotatably connected to the mounting frame 21 fixed on the back side of the workbench 1, the Maltese cross movement assembly is connected to the gear 23 through the second transmission belt 22, the rotating worm 5 drives the worm wheel 17 to rotate, and the worm wheel 17 drives the Maltese cross movement assembly The work then drives the gear 23 to rotate i...

Embodiment 3

[0041] An assembly method of a robot for automatic production of bolt assembly, comprising the steps of:

[0042] Step 1, reset, check whether the supporting plate is in the initial position under the gear, if not, press the switch in reverse to make the electric motor drive the worm to reverse and reset the supporting plate;

[0043] Step 2, installation, fix the workpiece on the pallet, and insert the bolts into the assembly holes;

[0044] Step 3, assemble, start the electric motor in the forward direction, use the locking mechanism and the moving mechanism to drive the hexagonal lock sleeve to move up and down reciprocally and rotate and lock, while the gear drives the pallet to feed intermittently;

[0045] Step 4, complete, turn off the switch after all the bolts on the supporting plate have passed through the hexagonal lock sleeve, remove the workpiece installed on the supporting plate, and check the locking condition of the bolts.

[0046] According to the specific de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com