Full-automatic single crystal silicon rod cutting and grinding combined processing integrated equipment and using method thereof

A single crystal silicon rod and composite processing technology, which is applied in stone processing equipment, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low processing efficiency, long time consumption, and processing accuracy affecting the processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Below in conjunction with accompanying drawing, the present invention will be further described

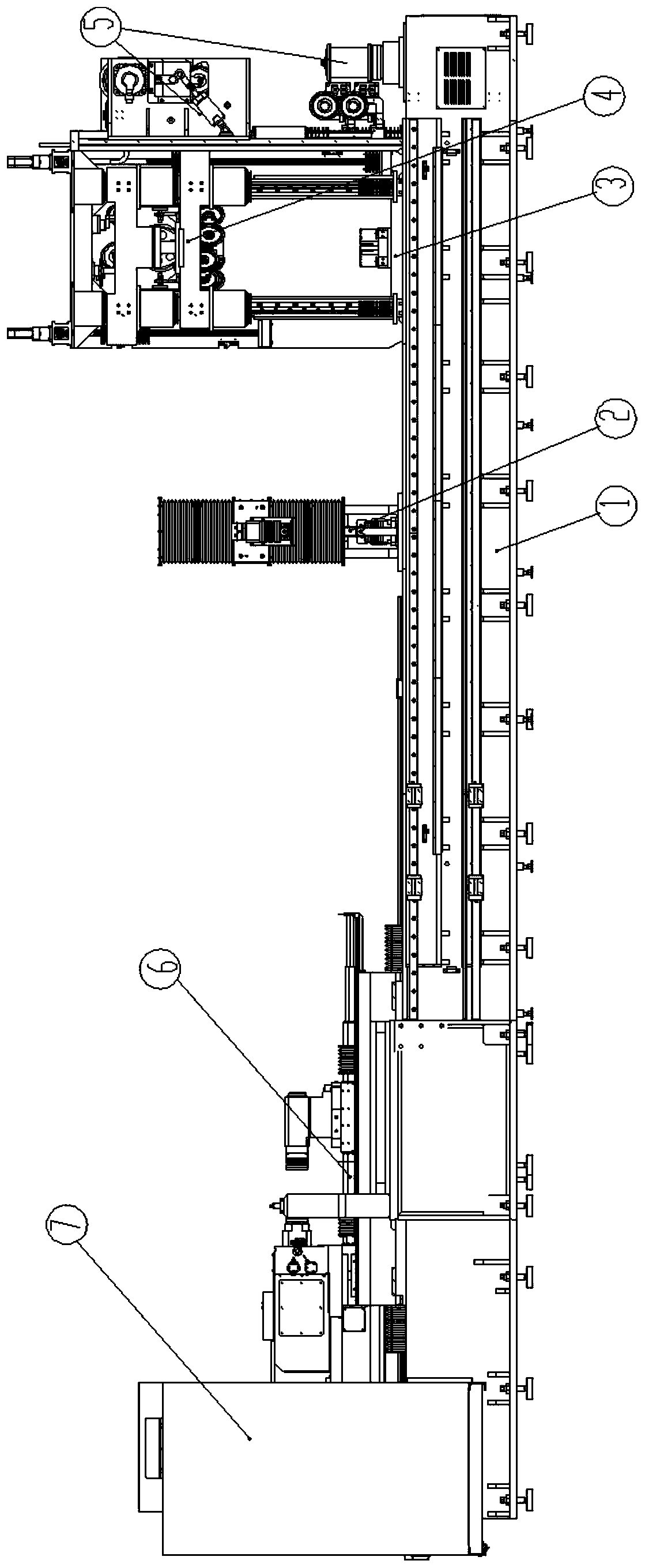

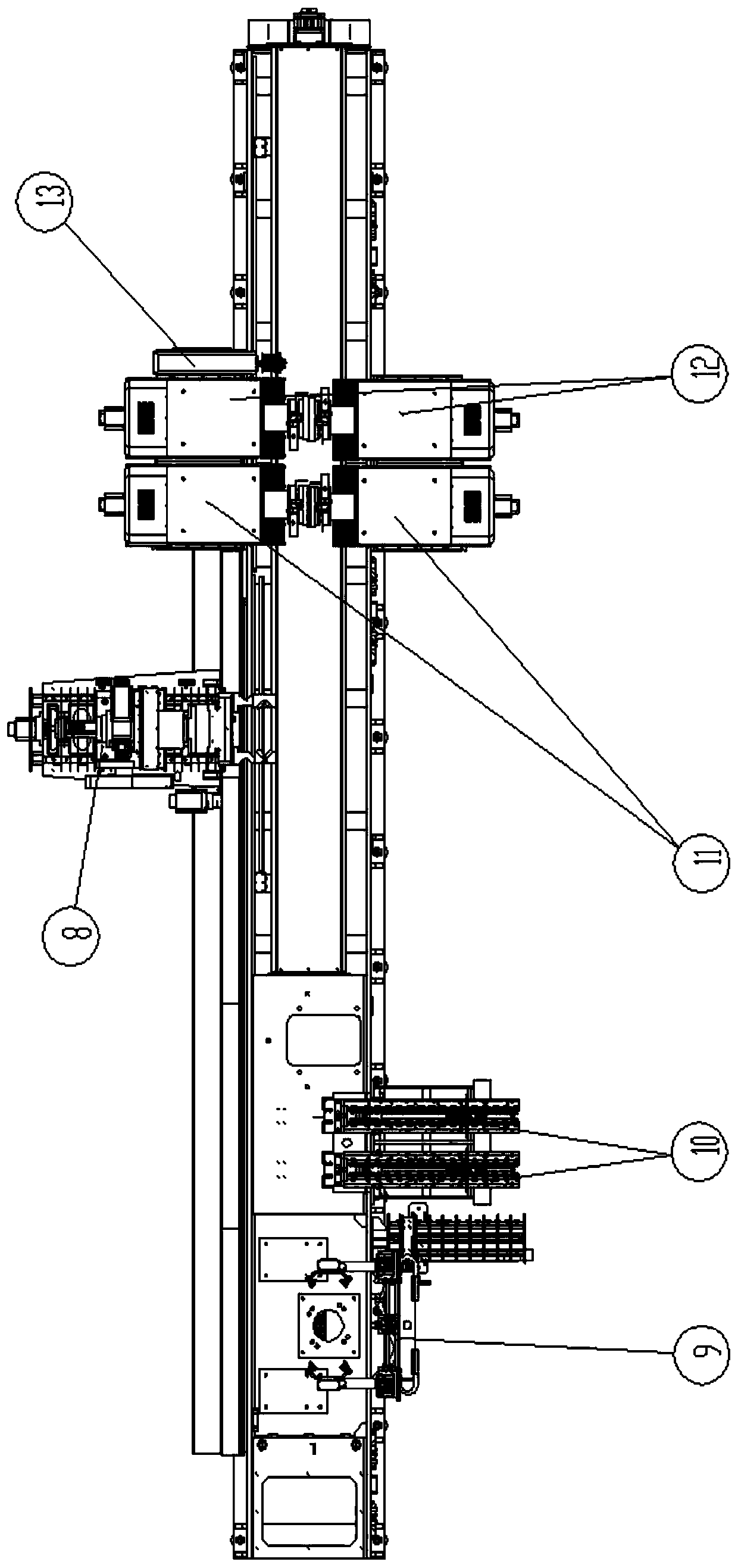

[0086] A fully automatic monocrystalline silicon rod cutting and grinding compound processing integrated equipment, which also includes a loading and unloading storage table, a crystal orientation detection unit, a manipulator assembly, a square cutting and feeding assembly, a wire arrangement mechanism, a side skin retrieving mechanism, and a coarse grinding power head, precision grinding power head, size detection unit, valve box, control cabinet;

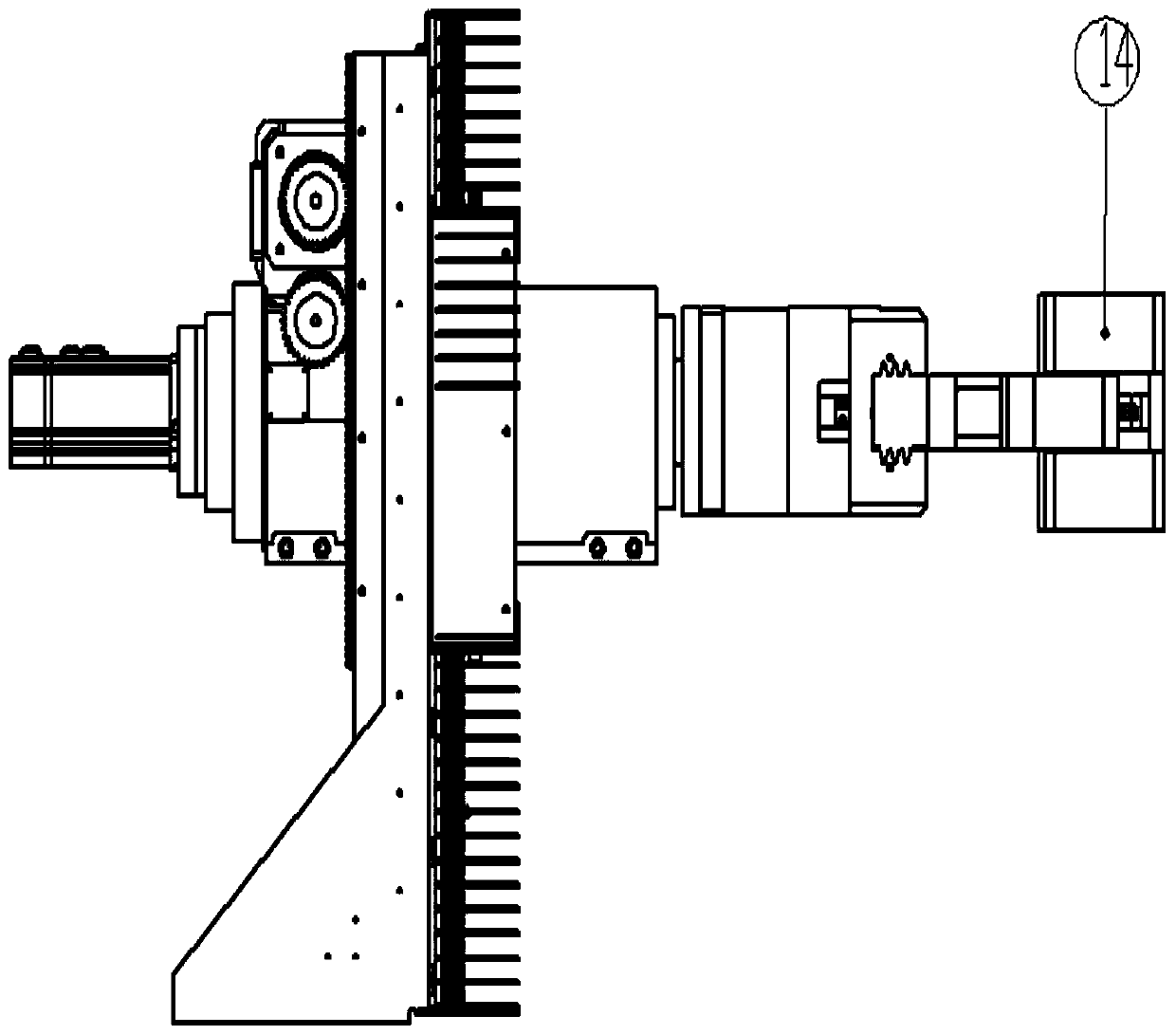

[0087] The square cutting and feeding assembly includes a square cutting gantry frame, a crystal bar clamping assembly, a cutting guide wheel feeding assembly, and a reversing guide wheel assembly. The crystal rod clamping assembly and the cutting guide wheel feeding assembly are respectively installed on the gantry The guide rail slider on the frame can move up and down driven by the servo motor and ball screw;

[0088] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com