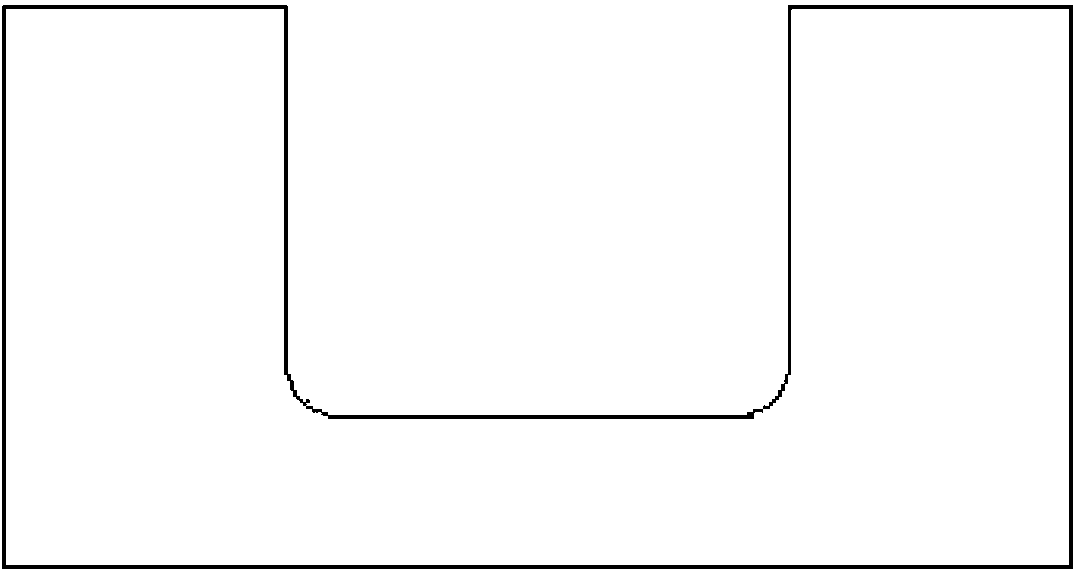

Method for manufacturing titanium alloy U-shaped material

A production method, titanium alloy technology, applied in the direction of metal rolling, etc., can solve the problems that cannot meet the requirements of high strength, it is difficult to produce profiles in large quantities, and the utilization rate of materials is low, so as to achieve good quality, reduce product cost, The effect of high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for producing a titanium alloy U-shaped bar, comprising the steps of:

[0029] 1. The raw material is titanium alloy round bar blank of grade TA15, Φ90mm×1100mm.

[0030] 2. After the bar is heated to 980° C. with a box-type resistance furnace, it is rolled into a square bar of 48 × 48 × 3000 mm with a 430 horizontal open-end rolling mill.

[0031] 3. After flaw detection with an ultrasonic flaw detector, saw and cut into 1000mm long material sections, and use a portable grinder to grind the surface so that there are no cracks or defects on the surface.

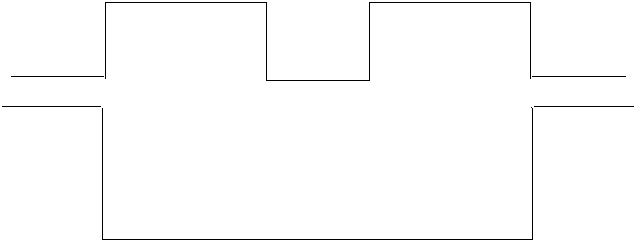

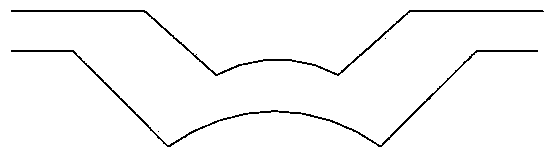

[0032] 4. Then heat it up to 960°C with a box-type resistance furnace, keep it warm for 1 hour, and send it to the first two stands of the Φ280 horizontal open-end rolling mill equipped with a plate-type position guide device. The rolling speed is 1m per second, and 6 passes are carried out in sequence Rolling, design the dies for the 6-pass rolling passes in turn, and the 6-pass rolling passes are 3-K11—3-K6...

Embodiment 2

[0042] A method for producing a titanium alloy U-shaped bar, comprising the steps of:

[0043] 1. The raw material is titanium alloy round bar blank of brand TC2, Φ90mm×1100mm.

[0044] 2. After the bar is heated to 1020° C. with a box-type resistance furnace, it is rolled into a square bar of 48×48×3000 mm with a 430 horizontal open-end rolling mill.

[0045] 3. After flaw detection with an ultrasonic flaw detector, saw and cut into 1000mm long material sections, and use a portable grinder to grind the surface so that there are no cracks or defects on the surface.

[0046] 4. Then heat it up to 980°C with a box-type resistance furnace, keep it warm for 1 hour, and send it to the first two stands of the Φ280 horizontal open-end rolling mill equipped with a plate-type guide device. The rolling speed is 3m per second, and 6 passes are carried out in sequence. Rolling, design the dies for the 6-pass rolling passes in turn, and the 6-pass rolling passes are 3-K11—3-K6, such as ...

Embodiment 3

[0056] A method for producing a titanium alloy U-shaped bar, comprising the steps of:

[0057] 1. The raw material is titanium alloy round bar blank of brand TC2, Φ90mm×1100mm.

[0058] 2. After the bar is heated to 1000° C. with a box-type resistance furnace, it is rolled into a square bar of 48×48×3000 mm with a 430 horizontal open-end rolling mill.

[0059] 3. After flaw detection with an ultrasonic flaw detector, saw and cut into 1000mm long material sections, and use a portable grinder to grind the surface so that there are no cracks or defects on the surface.

[0060] 4. Then heat it up to 970°C with a box-type resistance furnace, keep it warm for 1 hour, and send it to the first two stands of the Φ280 horizontal open-end rolling mill equipped with a plate-type guide device. The rolling speed is 2m per second, and 6 passes are carried out in sequence Rolling, design the dies for the 6-pass rolling passes in turn, and the 6-pass rolling passes are 3-K11—3-K6, such as F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com