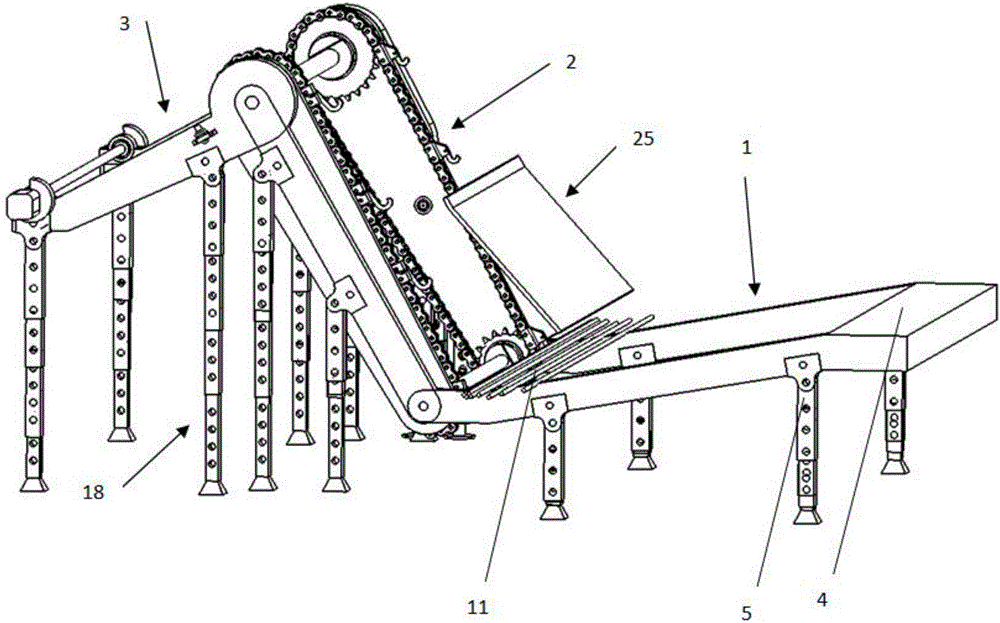

Automatic sorting and conveying device

A technology of conveying device and conveying rack, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of complex structure, loud noise, different lengths and specifications of rods, etc., and achieves compact structure, wide adaptability and good feasibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

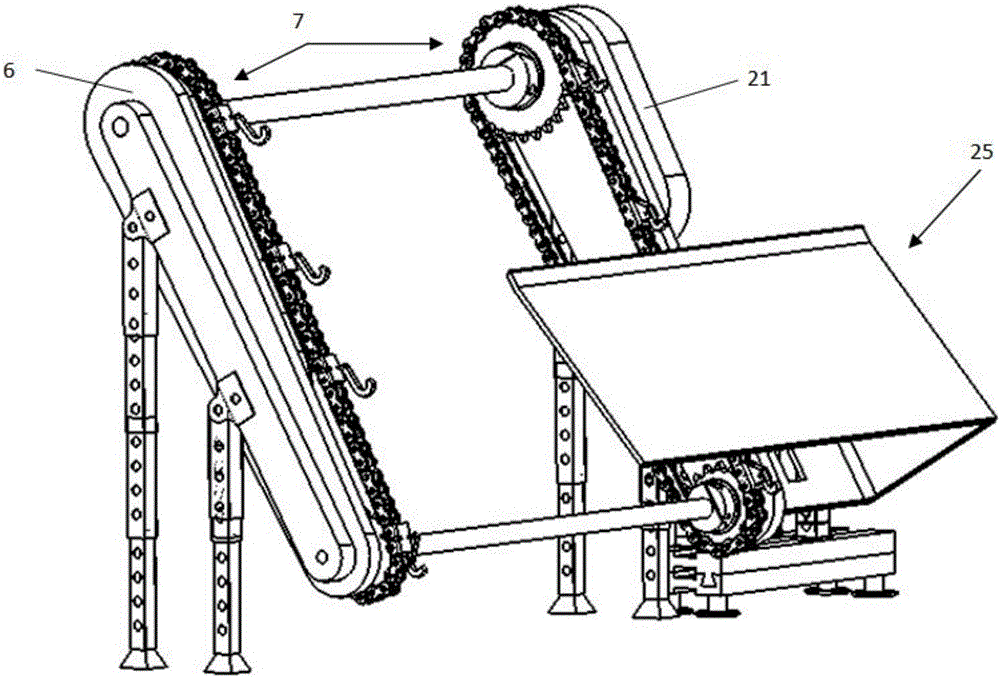

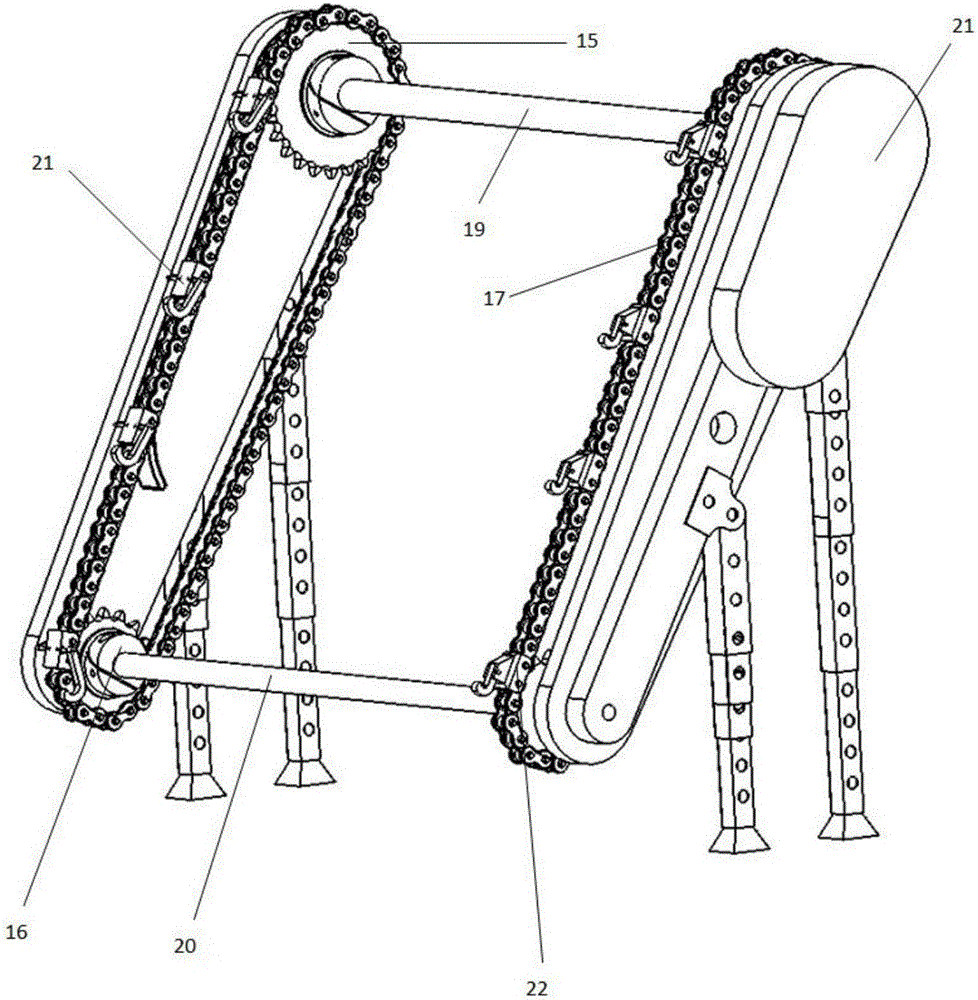

Method used

Image

Examples

Embodiment

[0032] As an embodiment of the present invention, the single-chip microcomputer can adopt the MCS-51 series of INTEL Company, such as 89C52; the first motor 21 and the second motor 13 can adopt existing servo motors on the market, such as the Baofuli motor 6UG-20K Model; the counting sensor can adopt the infrared sensor of HD-DS30CM type; the above-mentioned devices can be used in the automatic sorting and conveying device in the present invention, but are not limited to the above-mentioned models.

[0033] In the factory, during the automatic sorting and feeding process of the slender circular rod materials 11, when starting to work, a bundle of materials 11 is placed on the feeding rack 4 of the feeding unit 1, and the feeding rack 4 is close to the baffle plate 34 One side is lower than the other side, and the material 11 slides against the baffle plate 34 on the lower side of the upper material rack 4. At this time, the material 11 is aligned along the baffle plate 34, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com