Preparing method for Ti45Nb alloy disc circular wire

A technology of alloy disk and round wire, which is applied in the field of preparation of Ti45Nb alloy disk and round wire, can solve the problems of low dimensional accuracy control level and poor surface quality, and achieves fine and uniform horizontal and vertical structure, stable performance and obvious vertical streamline. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

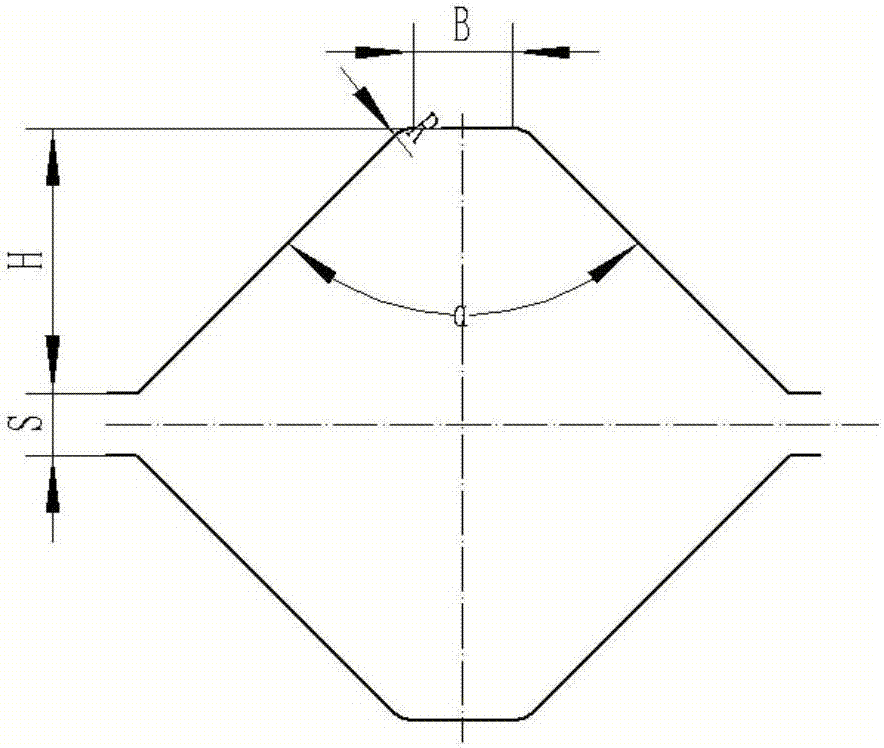

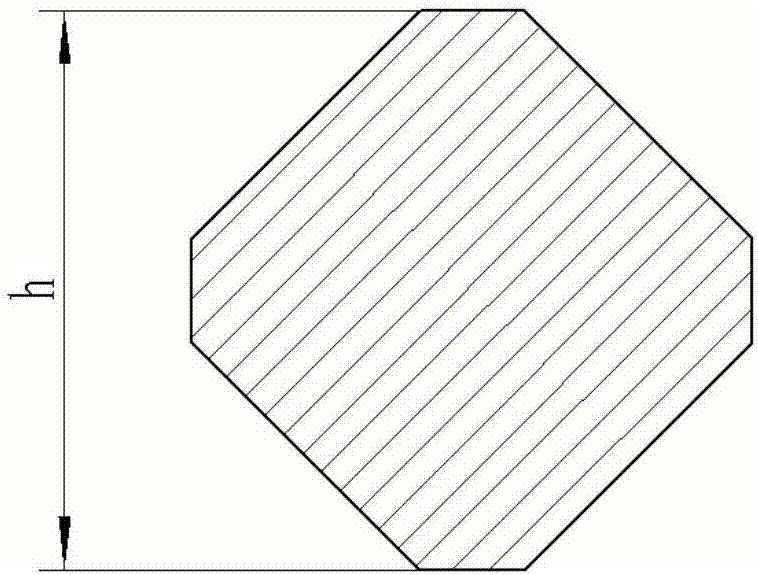

[0049] Step 1, use a Φ18.5mm Ti45Nb alloy polished bar with uniform composition and uniform horizontal and vertical structures, use a two-roller reversible cold rolling mill, rolls with square holes, roll 9 passes, and the pass deformation is 11% to 17%, rolled to a square bar billet of 11.7mm square.

[0050] Step 2, use a wire drawing machine to round the square bar blank obtained by cold-rolling the pass in step 1, and use a double-type square-to-round pass roll die to round it in one pass, and the deformation of the round pass is 16% to 18 %. After 5 passes of rounding, the roller mold draws the wire to Φ8.0mm, and the deformation of the drawing pass is 13% to 15%.

[0051] Step 3: anneal the Φ8.0mm coiled wire obtained in step 2 in a vacuum furnace at a holding temperature of 790° C. to 820° C. for 1 h to 2 h, and cool in a furnace.

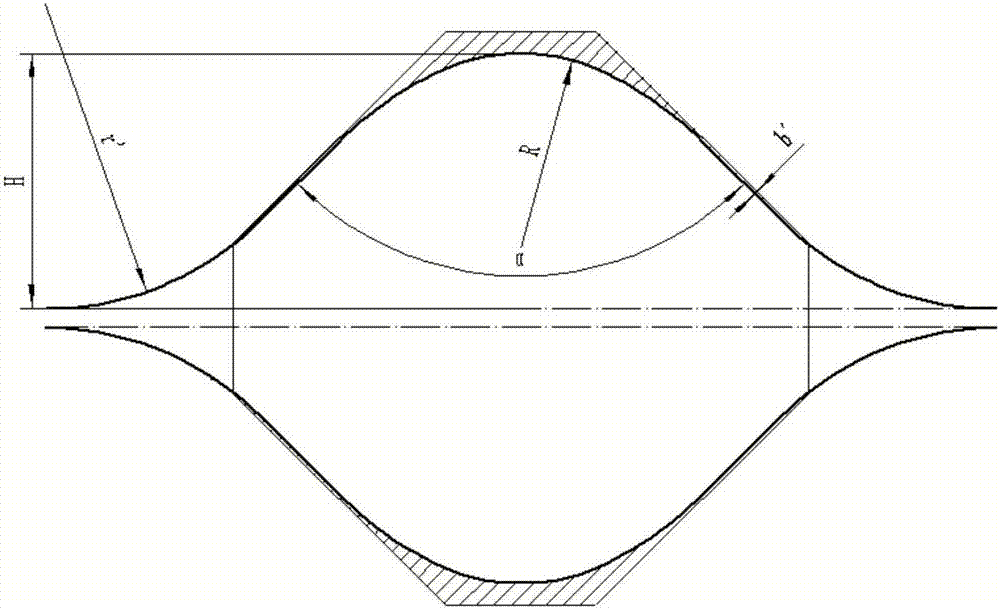

[0052] Step 4, obtain Φ8.0mm round wire material through step 3, use the cold tandem rolling mill, the rolls installed alternately horizo...

Embodiment 2

[0055] Step 1, use a Φ17.5mm Ti45Nb alloy polished bar with uniform composition and uniform horizontal and vertical structures, use a two-roller reversible cold rolling mill, rolls with square holes, roll 6 passes, and the pass deformation is 3% to 14%, rolled to a 12mm square bar.

[0056] Step 2, use a wire drawing machine to round the square bar billet obtained by cold-rolling the pass in step 1, and use a double-type square-to-round pass roll die to round it in one pass, and the deformation of the round pass is 13% to 15% %. After rounding, the roller dies are drawn to a Φ8.0mm round wire in 7 passes, and the deformation of the drawing passes is 10% to 13%.

[0057] Step 3: anneal the Φ8.0mm coiled wire material obtained in step 2 in a vacuum furnace at a holding temperature of 820° C. to 850° C. for 1 h to 2 h, and cool in a furnace.

[0058] Step 4, use the Φ8.0mm round wire material obtained in step 3, and use the cold tandem rolling mill to cold-roll the rolls instal...

Embodiment 3

[0061] Step 1, use a Φ18.5mm Ti45Nb alloy polished bar with uniform composition and uniform horizontal and vertical structures, use a two-roller reversible cold rolling mill, rolls with square grooves, roll 16 passes, and the pass deformation is 5% to 15%, rolled to a 9.1mm square billet.

[0062] Step 2, use a wire drawing machine to round the square bar blank obtained by cold-rolling the pass in step 1, and use a two-unit square-to-round pass roll die to round it in one pass, and the deformation of the round pass is 12% to 14 %. After rounding, the roller die draws the wire to Φ8.0mm in one pass, and the deformation of the drawing pass is 11% to 13%.

[0063] Step 3: anneal the Φ8.0mm coiled wire material obtained in step 2 in a vacuum furnace at a holding temperature of 850° C. to 870° C. for 1 h to 2 h, and cool in a furnace.

[0064] Step 4, use the Φ8.0mm coiled wire material obtained in step 3, and use the cold tandem rolling mill to cold-roll the rolls installed alte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com