Machining center for polishing and grinding square rod

A grinding and grinding wheel technology, applied in metal processing equipment, grinding machines, manufacturing tools, etc., can solve the problems of high defective rate, affecting production efficiency, processing accuracy of excellent rate, etc., achieve high degree of automation, improve efficiency and excellent rate , The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

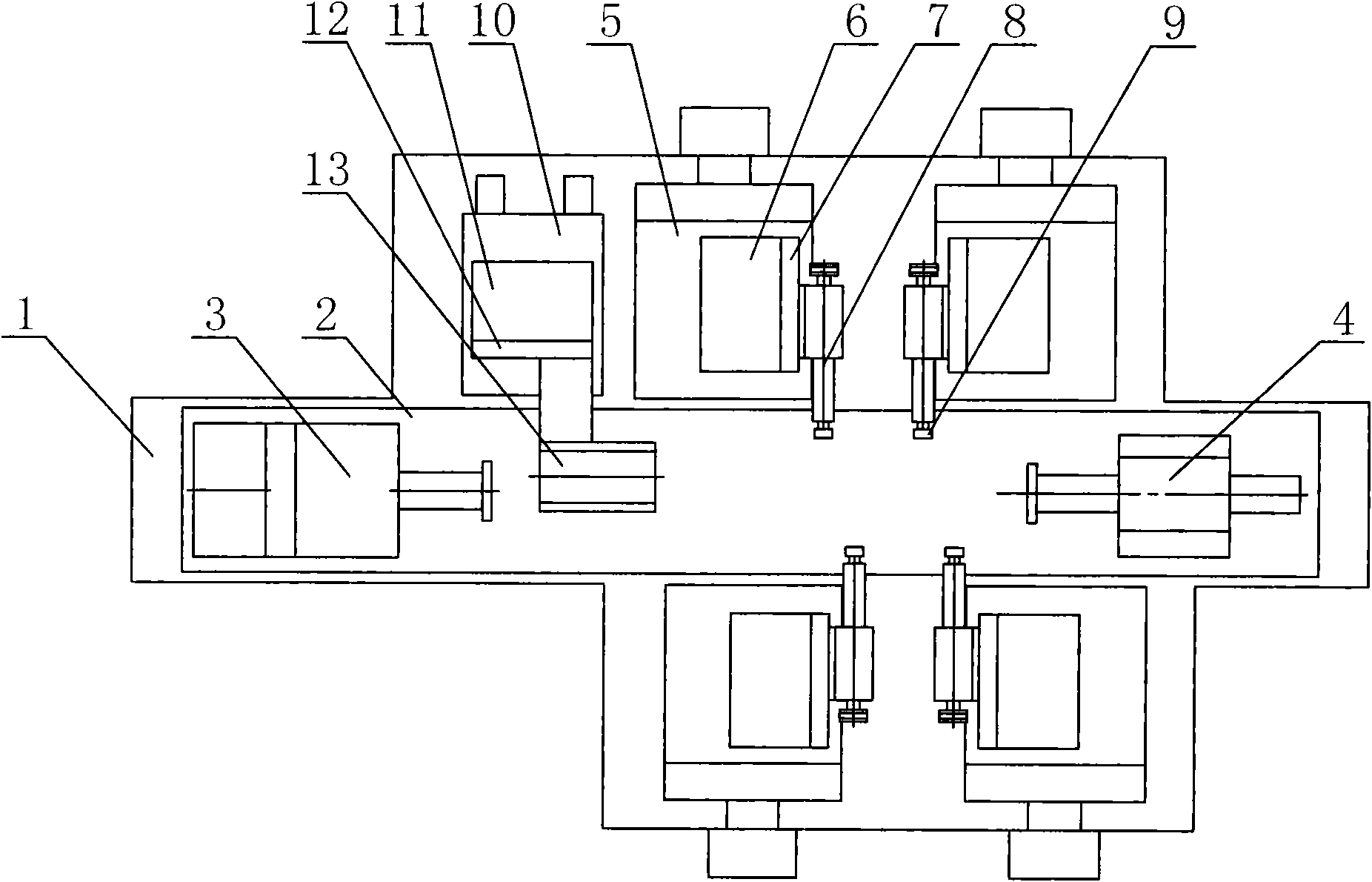

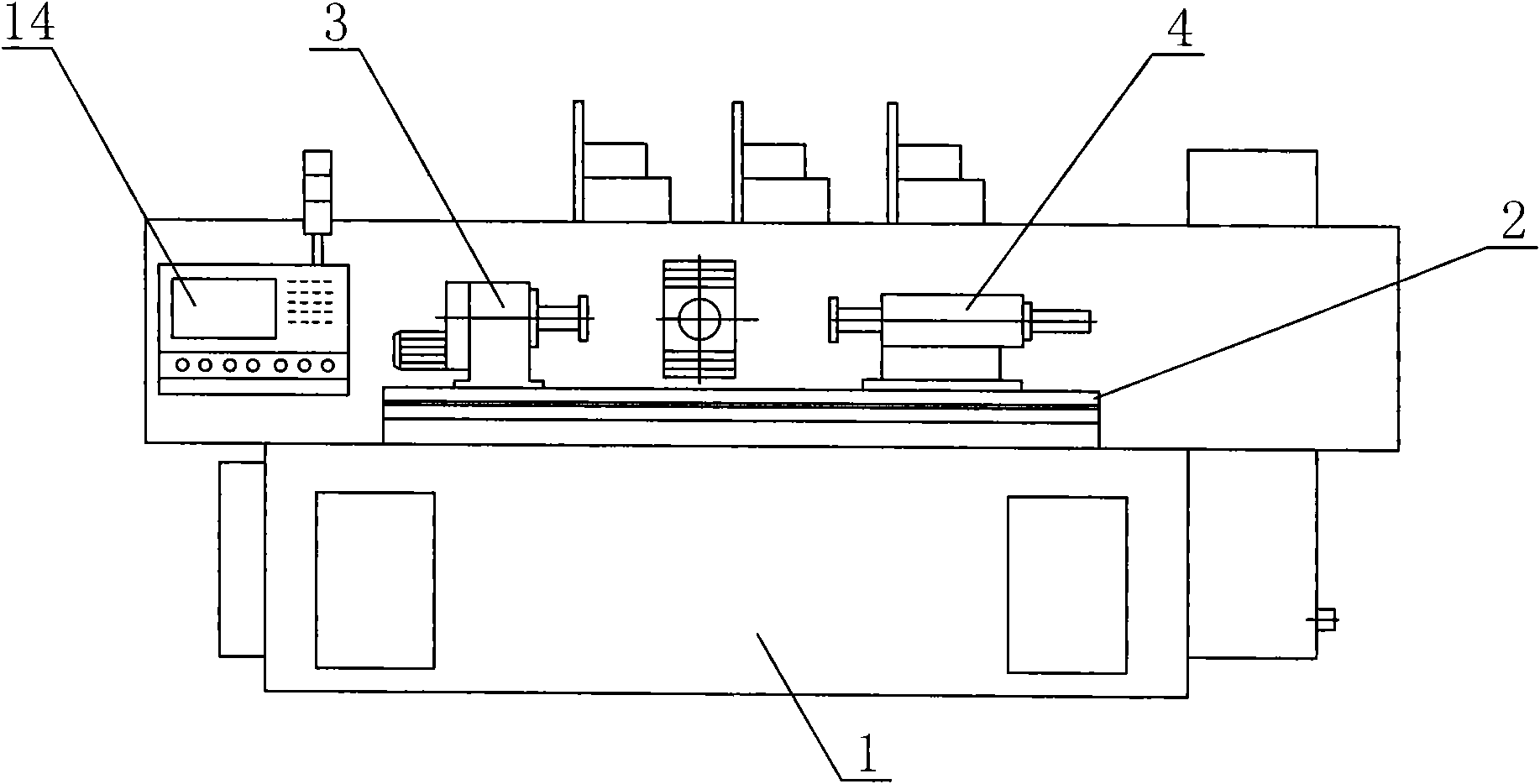

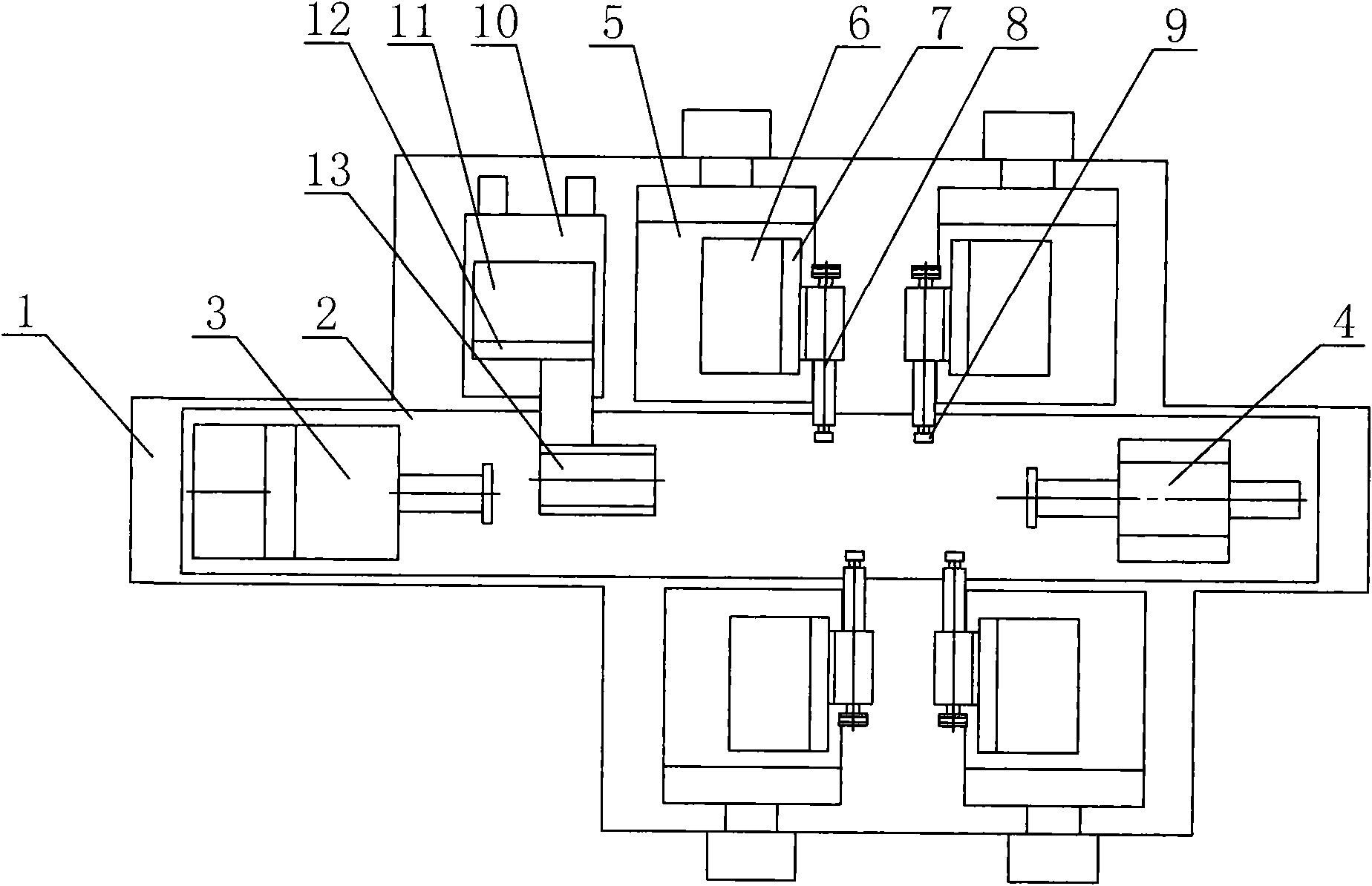

[0014] Such as Figure 1-2 As shown, the square bar polishing machining center described in the embodiment of the present invention includes a bed 1 and a workbench 2 installed on the bed 1, a bar clamping device, a bar positioning device, a grinding device and a numerical control device 14, wherein, driven by a servo motor, the workbench 2 can perform horizontal reciprocating motion relative to the bed 1 along the track; the two ends of the workbench 2 are respectively installed with a bedside box 3 and a tailstock 4, which form a bar clamping device, the bedside box 3 is driven by a servo motor, and can be indexed or continuously rotated according to the program of the numerical control device 14; two groups of grinding devices are installed on the bed 1 along both sides of the movable workbench 2, and each group of grinding devices Both include a saddle 5, a column 6, a lifting slide plate 7, and a grinding wheel spindle 8. A column 6 is set on the sliding saddle 5, and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com