Ratchet wrench

A ratchet wrench and wrench body technology, applied in the ratchet wrench field, can solve the problems of easy jamming, inability to use, limited use space and angle, etc., and achieve the effects of convenient use, easy manufacture and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

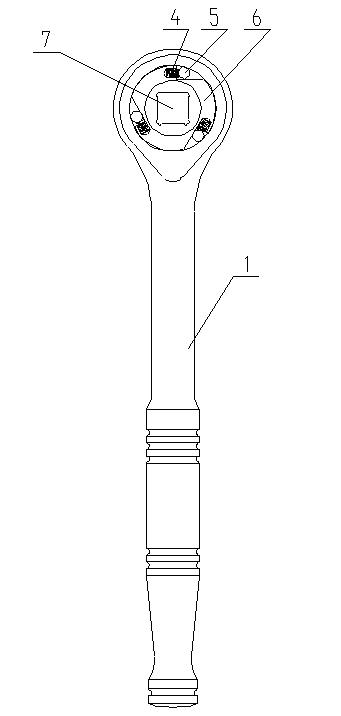

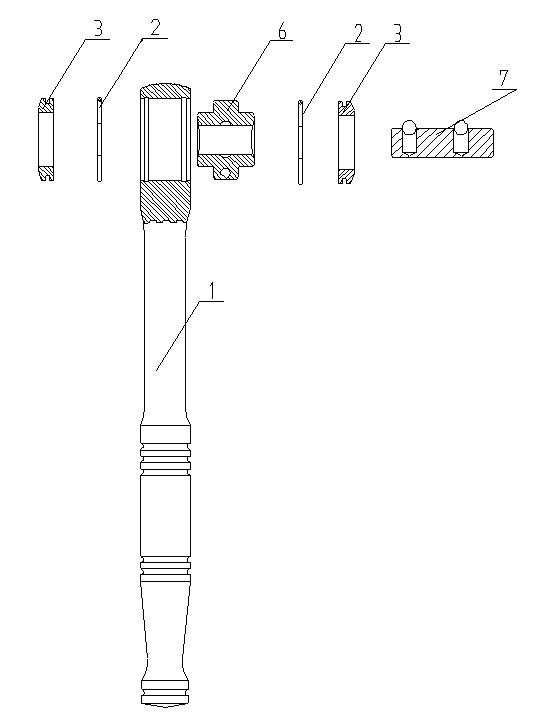

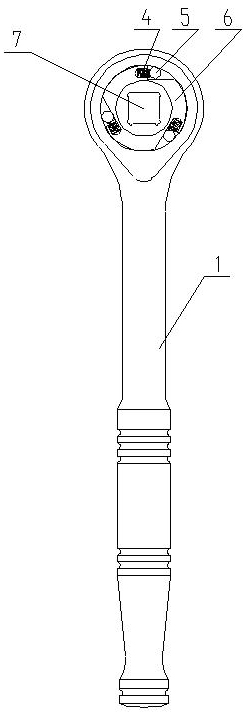

[0011] Such as figure 1 , figure 2 Shown: a ratchet wrench, one end of the handle 1 is connected to the head, the head is provided with a round hole, the inner edge of the round hole is provided with ring-shaped slots at both ends, and the round hole is provided with a rotatable wrench head 6 , the middle of the wrench head is provided with a square through hole, and the middle of one side of the through hole is provided with a groove. A round hole is arranged on the plane, a spring 4 is arranged in the round hole, a needle roller 5 is arranged in the gap, the wrench head is accommodated in the middle of the round hole, end caps 3 are arranged at both ends, and an annular groove is arranged on the end cap, A retaining ring 2 is arranged in the annular groove, and the retaining ring enters the ring-shaped draw-in groove on the inner edge of the circular hole to fix the end cover 3 . There are 3 breaches evenly distributed on the middle circumference of the pull body head, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com