Inorganic composite A-class non-combustible insulation board and preparation method thereof

An inorganic composite, thermal insulation board technology, applied in thermal insulation, building components, fire prevention and other directions, can solve the problems of easy hollowing and cracking, application limitation, limited energy saving effect, etc., to achieve convenient and fast construction operation, improve overall fire performance, excellent thermal insulation The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

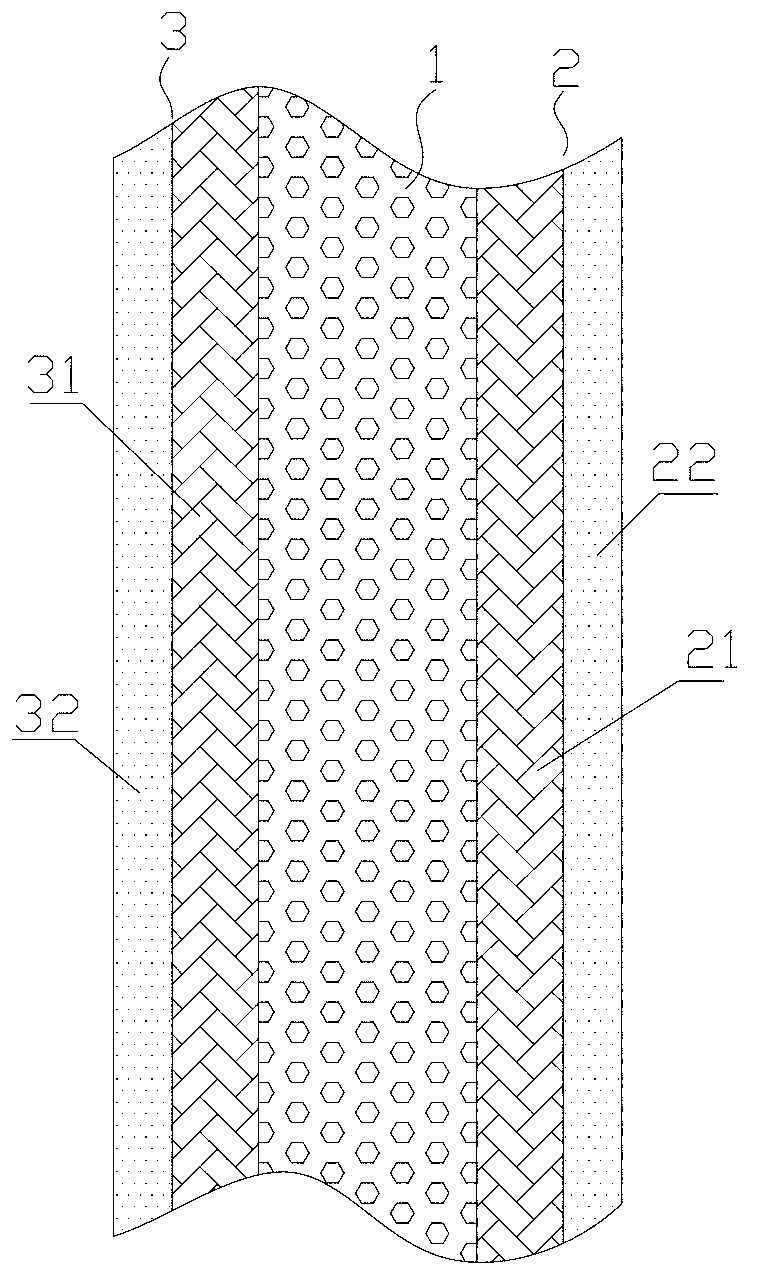

[0047] This embodiment is a preferred implementation of the present invention, see figure 1 , the inorganic composite grade A non-combustible thermal insulation board provided in this embodiment comprises a thermal insulation core material layer 1, the outer surface and inner surface of the thermal insulation core material layer 1 are respectively provided with a first interface enhancement layer 2 and a second interface enhancement layer 3, the first The interface strengthening layer 2 includes a first alkali-resistant mesh cloth layer 21 located in the inner layer and a first polymer waterproof and crack-resistant mortar layer 22 located in the outer layer, and the second interface enhancing layer 3 includes a second alkali-resistant mesh cloth located in the inner layer Layer 31 and the second polymer waterproof and anti-crack mortar layer 32 located in the outer layer. The second alkali-resistant mesh layer 31 and the first alkali-resistant mesh layer 21 are coated on the ...

Embodiment 2

[0087] This example is another embodiment of the present invention, except that the composition of the insulating mortar constituting the insulating core material layer 1 and the composition of the mortar constituting the polymer waterproof and anti-cracking mortar layer are different from Example 1, its basic structure and preparation method Same as embodiment one.

[0088] The thermal insulation core material layer 1 of this embodiment is composed of thermal insulation mortar with the following weight ratio:

[0089] 650 parts of ordinary silicon 42.5 cement, 240 parts of fly ash, 60 parts of gray calcium, 80 parts of inorganic mineral filler, 18 parts of redispersible latex powder, 6 parts of water retaining agent, 5 parts of water reducing agent, 0.2 part of defoamer, 0.4 parts of air-entraining agent, 3 parts of polypropylene fiber, 4 parts of water-repellent agent, 5 parts of lignin, B1 primary foamed polystyrene particles (7-8kg / m 3 )35 parts, inorganic vitrified micro...

Embodiment 3

[0093] This example is another embodiment of the present invention, except that the composition of the insulating mortar constituting the insulating core material layer 1 and the composition of the mortar constituting the polymer waterproof and anti-cracking mortar layer are different from Example 1, its basic structure and preparation method Same as embodiment one.

[0094] The thermal insulation core material layer 1 of this embodiment is composed of thermal insulation mortar with the following weight ratio:

[0095] 750 parts of ordinary silicon 42.5 cement, 200 parts of fly ash, 55 parts of gray calcium, 60 parts of inorganic mineral filler, 15 parts of redispersible latex powder, 4 parts of water retaining agent, 4 parts of water reducing agent, 0.1 part of defoamer, 0.5 parts of air-entraining agent, 2 parts of polypropylene fiber, 2 parts of water-repellent agent, 4 parts of lignin, B1 primary foamed polystyrene particles (7-8kg / m 3 )38 parts, inorganic vitrified micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com