Light anti-sunning heat preservation flame-retardant plate for decorating

A technology of flame retardant board and thermal insulation board, applied in thermal insulation, building components, coatings, etc., can solve the problems of application limitation, easy hollowing and cracking, poor thermal insulation performance, etc., to improve the overall fire performance, excellent thermal insulation The effect of thermal performance, good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

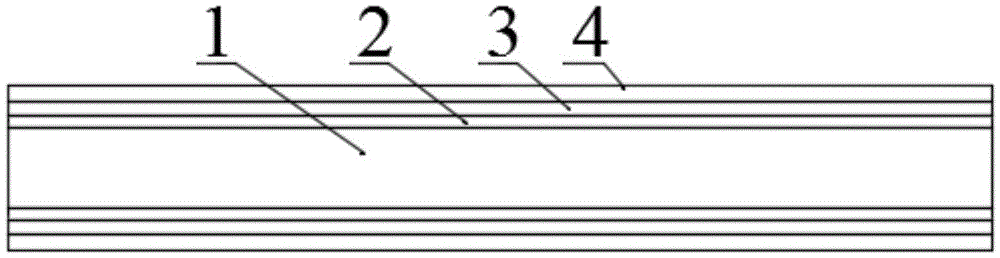

[0015] Such as figure 1 As shown, a light sunproof heat preservation flame retardant board for decoration, comprising a core material 1, a fabric surface 2 arranged on the two surfaces of the core material 1, each fabric surface 2 is provided with a layer of flame retardant coating on the outer surface Layer 3, the flame-retardant coating 3 is composed of mortar in the following weight ratio: 30 parts of polyurethane prepolymer, 2 parts of dibutyl phthalate, 0.5 parts of titanate coupling agent, and 3 parts of talcum powder , 3 parts of light calcium carbonate, 0.1 part of tributyl phosphate, 0.5 part of isopropanol, 10 parts of mixed solvent, 3 parts of flame retardant material; Sun-resistant coating 4, the sun-resistant coating 4 is made of the following components by weight: 50 parts of gelatin, 4 parts of titanium dioxide, 30 parts of light calcium carbonate, 5 parts of lithium tourmaline, lauryl 0.5 part of sodium sulfate, 2 parts of propylene glycol; the core material 1...

Embodiment 2

[0020] Such as figure 1 As shown, a light sunproof heat preservation flame retardant board for decoration, comprising a core material 1, a fabric surface 2 arranged on the two surfaces of the core material 1, each fabric surface 2 is provided with a layer of flame retardant coating on the outer surface Layer 3, the flame-retardant coating 3 is composed of mortar in the following weight ratio: 35 parts of polyurethane prepolymer, 3 parts of dibutyl phthalate, 0.8 parts of titanate coupling agent, 4 parts of talcum powder , 4 parts of light calcium carbonate, 0.3 part of tributyl phosphate, 0.8 part of isopropanol, 13 parts of mixed solvent, 4 parts of flame retardant material, the outer surface of the flame retardant coating 3 is coated with a layer of anti-sun Coating 4, the sun-resistant coating 4 is made of the following components by weight: 55 parts of gelatin, 4.5 parts of titanium dioxide, 35 parts of light calcium carbonate, 7 parts of lithium tourmaline, lauryl sulfate...

Embodiment 3

[0024] Such as figure 1 As shown, a light-weight sun-resistant, heat-preserving, and flame-retardant board for decoration includes a core material 1, fabric surfaces 2 arranged on both surfaces of the core material 1, and a layer of flame-retardant coating is provided on the outer surface of each fabric surface 2. Layer 3, the flame-retardant coating 3 is composed of mortar in the following weight ratio: 40 parts of polyurethane prepolymer, 4 parts of dibutyl phthalate, 1 part of titanate coupling agent, and 5 parts of talcum powder , 5 parts of light calcium carbonate, 0.5 part of tributyl phosphate, 1 part of isopropanol, 15 parts of mixed solvent, and 5 parts of flame-retardant material; Coating 4, the sun-resistant coating 4 is made of the following components by weight: 60 parts of gelatin, 5 parts of titanium dioxide, 40 parts of light calcium carbonate, 8 parts of lithium tourmaline, lauryl sulfate 1.0 parts of sodium, 3 parts of propylene glycol.

[0025] The thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com