Method for re-manufacturing flame-proof outer shell

A flameproof enclosure and remanufacturing technology, which is applied in the direction of sealing enclosures, manufacturing motor generators, substation/power distribution equipment enclosures, etc., can solve the problems of single function, short life, poor corrosion resistance, etc., and prevent unauthorized opening operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

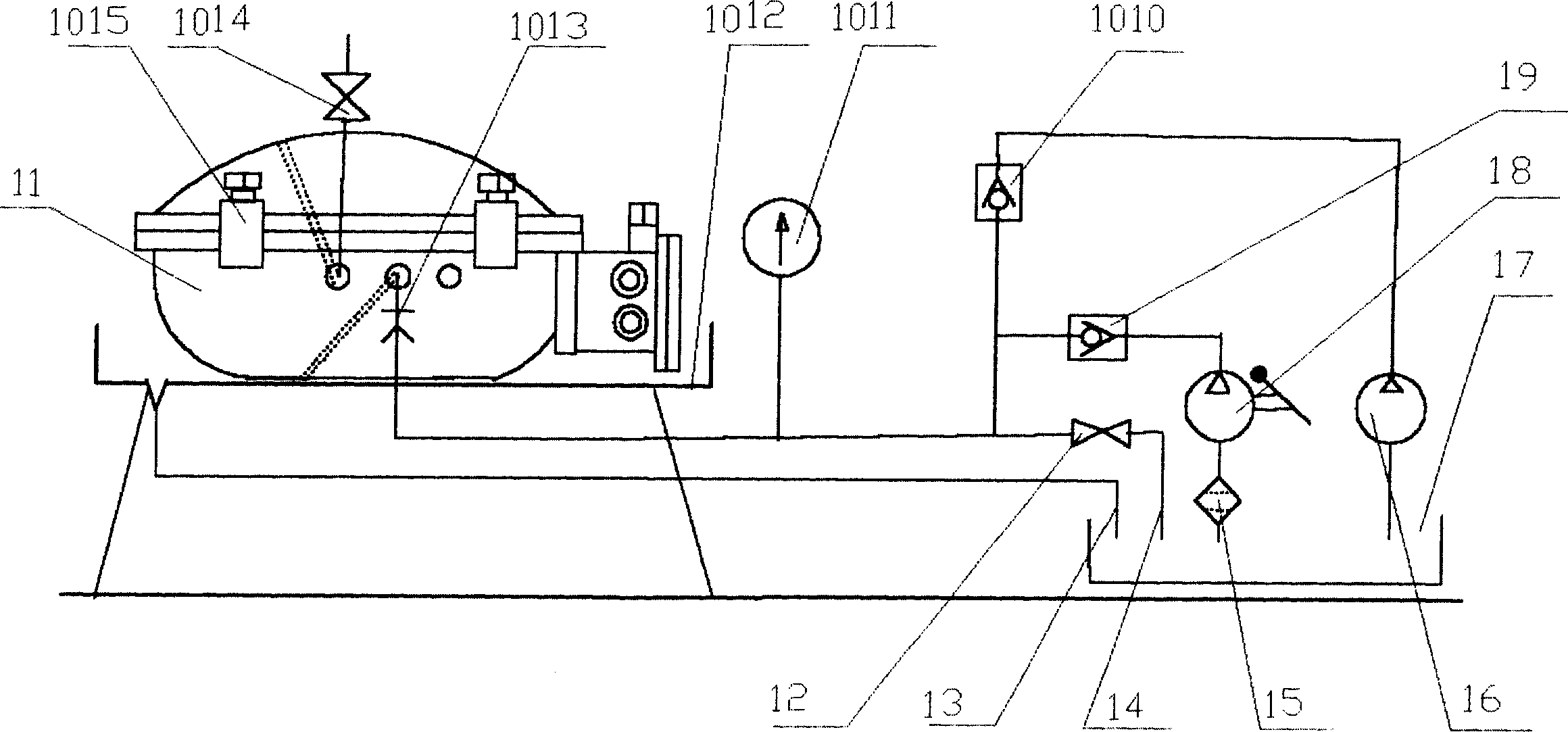

[0134] Flameproof enclosures for remanufactured switches (eg Figure 5 Shown) the specific way:

[0135] Decontamination of waste flameproof enclosures: in Figure (8), buy a car cleaning equipment (82), such as a "black cat" cleaning machine, make a cement platform, the middle of which is high and the sides are low, and the waste flameproof enclosures (81) Put it on the platform, wash it with a cleaning machine, the waste water flows from the platform to the pool (83) (waste water treatment device) for sedimentation and filtration, clean water is recycled, and after several times of recycling, replace with new water, and the recovered old water is sent to sewage treatment Station treatment, not random discharge. Frequently dig pool sludge and clean the pool. After the explosion-proof shell is cleaned, it is dried and sent to the next process. It can also be flushed with compressed air. Clean heavily polluted parts with aqueous solution. Oxyacetylene flame roasting can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com