Modified asphalt waterproof coiled material with heat insulation function and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in the direction of building insulation materials, protective devices, chemical instruments and methods, etc., and can solve the problems of no thermal insulation function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

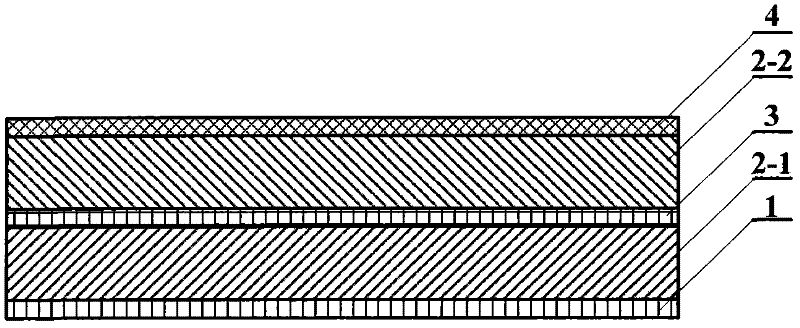

[0131] refer to figure 1 , making a modified asphalt waterproof coiled material with thermal insulation function provided by the present invention, comprising a base film 1, a first modified asphalt layer 2-1, a base layer 3, and a second modified asphalt layer 2-2; It is characterized in that it also includes a cover layer 4; wherein, the upper surface of the base film 1 has a first modified asphalt layer 2-1 and a second modified asphalt layer 2-2, and the first modified asphalt layer There is a base layer 3 between 2-1 and the second modified asphalt layer 2-2, and the covering layer 4 is on the upper surface of the second modified asphalt layer 2-2;

[0132] The thicknesses of the first modified asphalt layer 2-1 and the second modified asphalt layer 2-2 are respectively 1.5 mm;

[0133] The waterproof layer structure of the first modified asphalt layer 2-1, the second modified asphalt layer 2-2 and the base layer 3 is prepared as follows:

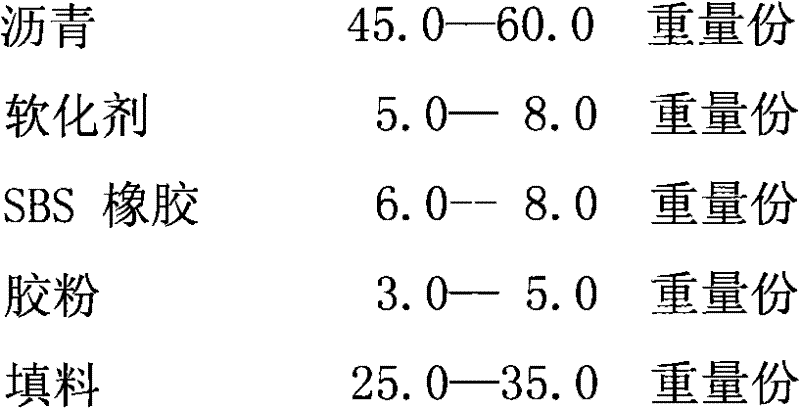

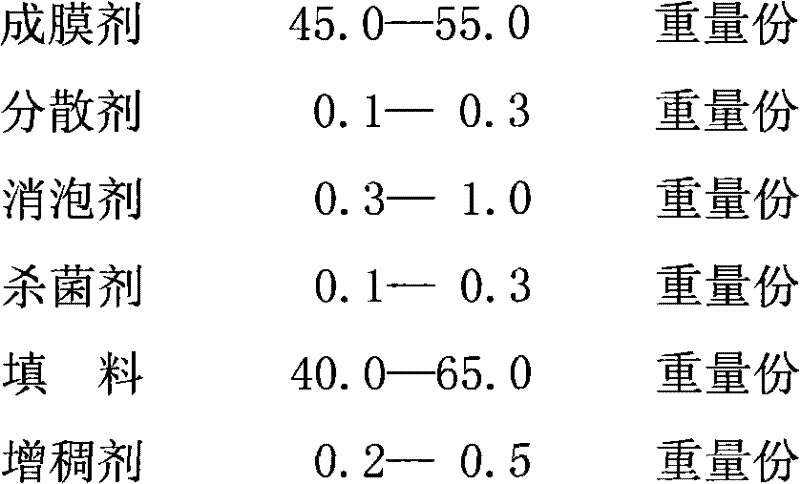

[0134] 1. Raw material ratio ...

Embodiment 2

[0171] refer to figure 1 , making a modified asphalt waterproof coiled material with thermal insulation function provided by the present invention, comprising a base film 1, a first modified asphalt layer 2-1, a base layer 3, and a second modified asphalt layer 2-2; It is characterized in that it also includes a cover layer 4; wherein, the upper surface of the base film 1 has a first modified asphalt layer 2-1 and a second modified asphalt layer 2-2, and the first modified asphalt layer There is a base layer 3 between 2-1 and the second modified asphalt layer 2-2, and the covering layer 4 is on the upper surface of the second modified asphalt layer 2-2;

[0172] The thicknesses of the first modified asphalt layer 2-1 and the second modified asphalt layer 2-2 are respectively 2.0mm;

[0173] The waterproof layer structure of the first modified asphalt layer 2-1, the second modified asphalt layer 2-2 and the base layer 3 is prepared as follows:

[0174] 1. Raw material ratio ...

Embodiment 3

[0212] refer to figure 1 , making a modified asphalt waterproof coiled material with thermal insulation function provided by the present invention, comprising a base film 1, a first modified asphalt layer 2-1, a base layer 3, and a second modified asphalt layer 2-2; It is characterized in that it also includes a cover layer 4; wherein, the upper surface of the base film 1 has a first modified asphalt layer 2-1 and a second modified asphalt layer 2-2, and the first modified asphalt layer There is a base layer 3 between 2-1 and the second modified asphalt layer 2-2, and the covering layer 4 is on the upper surface of the second modified asphalt layer 2-2;

[0213] The thicknesses of the first modified asphalt layer 2-1 and the second modified asphalt layer 2-2 are respectively 1.5 mm;

[0214] The waterproof layer structure of the first modified asphalt layer 2-1, the second modified asphalt layer 2-2 and the base layer 3 is prepared as follows:

[0215] 1. Raw material ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com