Ceramic kiln-path heat-recovering semiconductor thermal difference generation method and apparatus

A technology of waste heat recovery and temperature difference power generation, which is applied in the direction of generator/motor, waste heat treatment, electrical components, etc., to achieve the effect of long service life, small size and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

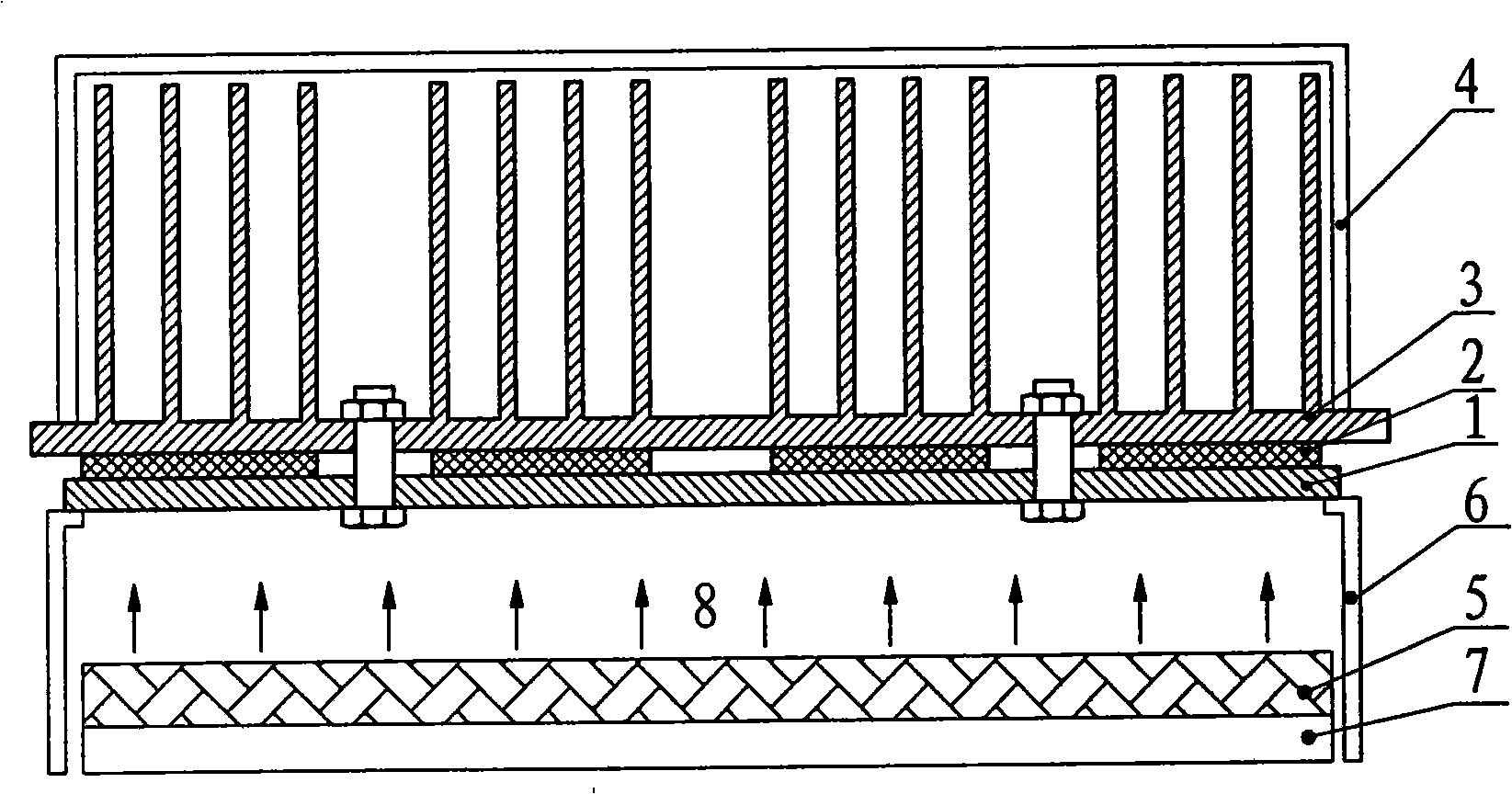

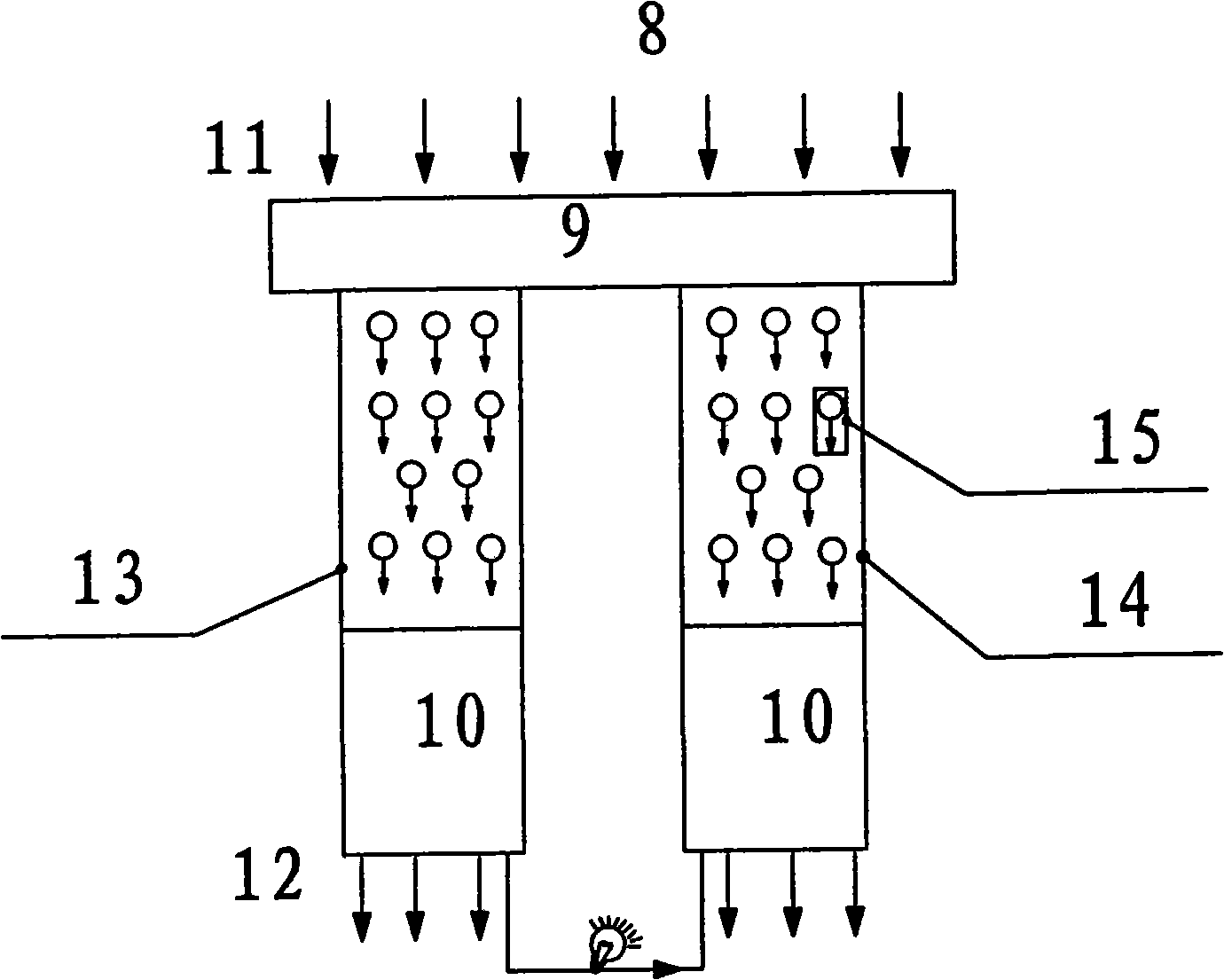

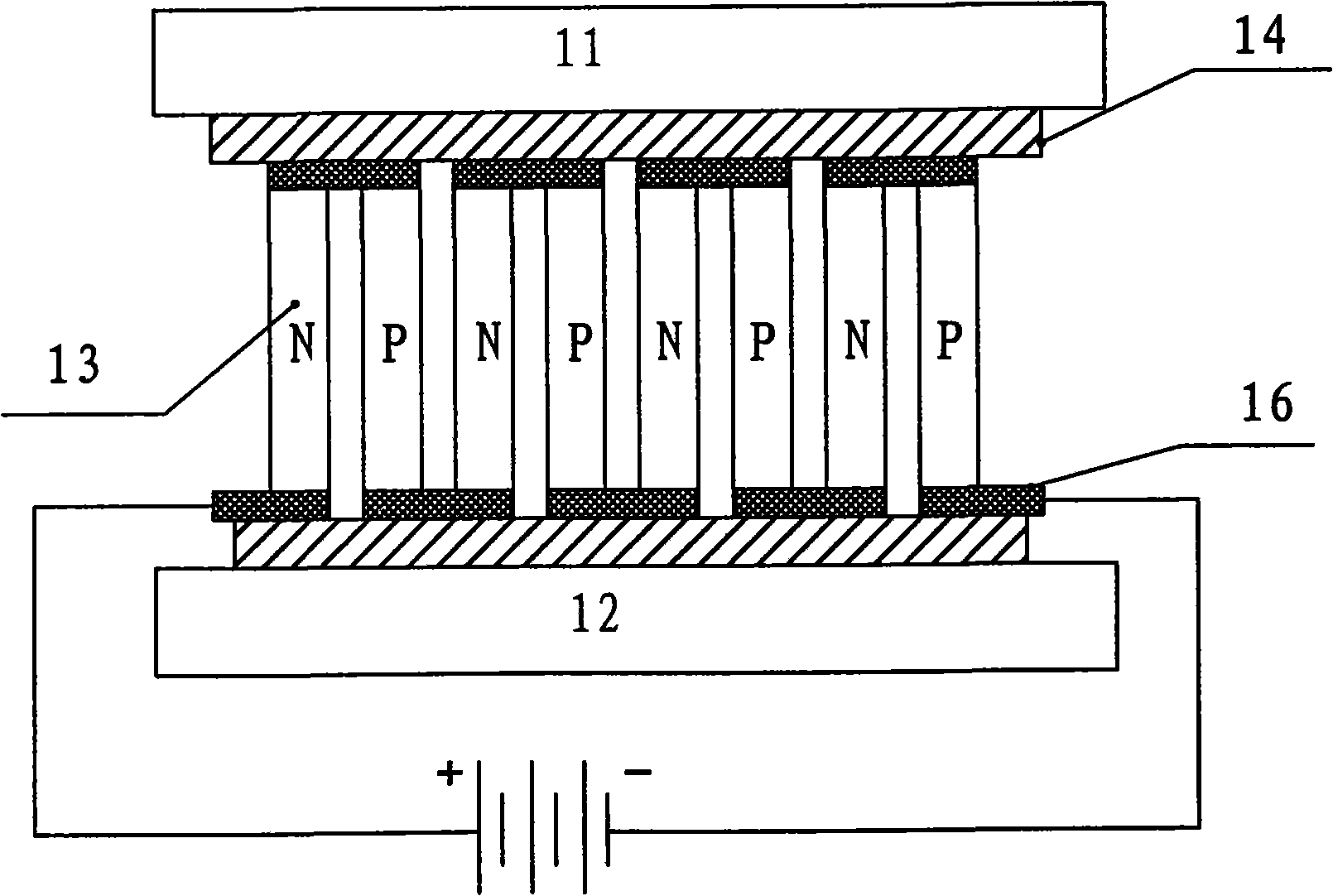

[0011] Control attached figure 1 , its structure includes a heat collecting plate 1, a semiconductor thermoelectric power generation module 2, a ribbed heat sink 3, and an isolation cover 4. Among them, the semiconductor thermoelectric power generation module 2 is sandwiched between the heat collector plate 1 and the ribbed heat sink 3, the heat collector plate 1 is closely attached to the lower side of the thermal surface of the semiconductor thermoelectric power generation module 2, and the ribbed heat sink 3 is closely attached to the semiconductor thermoelectric power generation module. 2. On the upper side of the cold surface, the semiconductor thermoelectric power generation module 2, the heat collecting plate 1, and the ribbed heat sink 3 are fastened together with bolts, so as to reduce the contact thermal resistance as much as possible and improve the efficiency of heat transfer. The semiconductor thermoelectric power generation module is tightly sandwiched between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com