Method for recovering Pb<2+> from electrolytic zinc rinsing wastewater with calcium-carbonate-modified kieselguhr

A technology of diatomite and calcium carbonate, which is applied in chemical instruments and methods, water/sewage treatment, process efficiency improvement, etc., can solve the problem of small adsorption capacity of diatomite and achieve the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

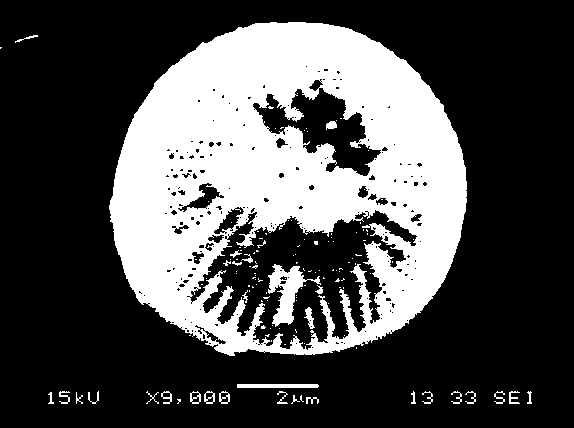

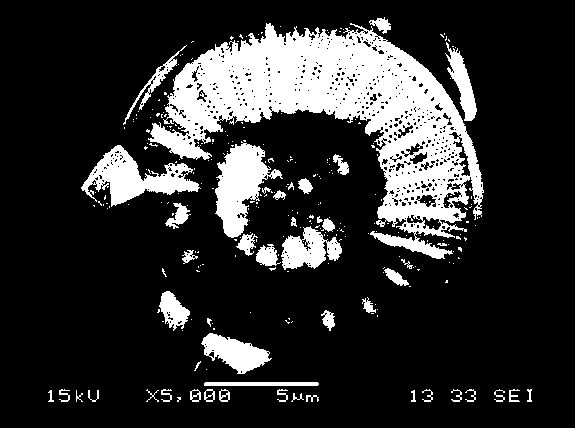

Image

Examples

Embodiment

[0013] (1) Take 10g of diatomaceous earth concentrate (after purification) and add it to 50 mL of Na with a concentration of 0.4mol / L 2 CO 3 solution, put it into a rotary constant temperature water bath shaker, stir at 25°C at 150r / min, slowly add 5mL of saturated CaCl dropwise 2 Continue to stir for 30 minutes and take it out, remove the upper layer solution, vacuum filter, then wash with pure water until neutral, centrifuge to separate the solid from the liquid, take the solid and dry it at 105°C, crush it through a 200-mesh sieve, and prepare calcium carbonate Modified diatomaceous earth adsorbent.

[0014] (2) Put 10 mL of the calcium carbonate modified diatomite adsorbent prepared in step (1) with a concentration of 0.1 g / L into a 250 mL conical flask with a stopper, and add 100 mL of Pb-containing 2+ The electrolytic zinc rinsing wastewater solution has an adsorption time of 120 minutes and an adsorption temperature of 25°C. After being covered, it is oscillated at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com