Method for mixing flocculant with motor vehicle cleaning sludge

A flocculant and motor vehicle technology, which is applied to the wastewater treatment of vehicle washing facilities, dehydration/drying/concentrated sludge treatment, etc. The effect of high atomization efficiency, promoting the improvement of sludge dewatering rate and reducing treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

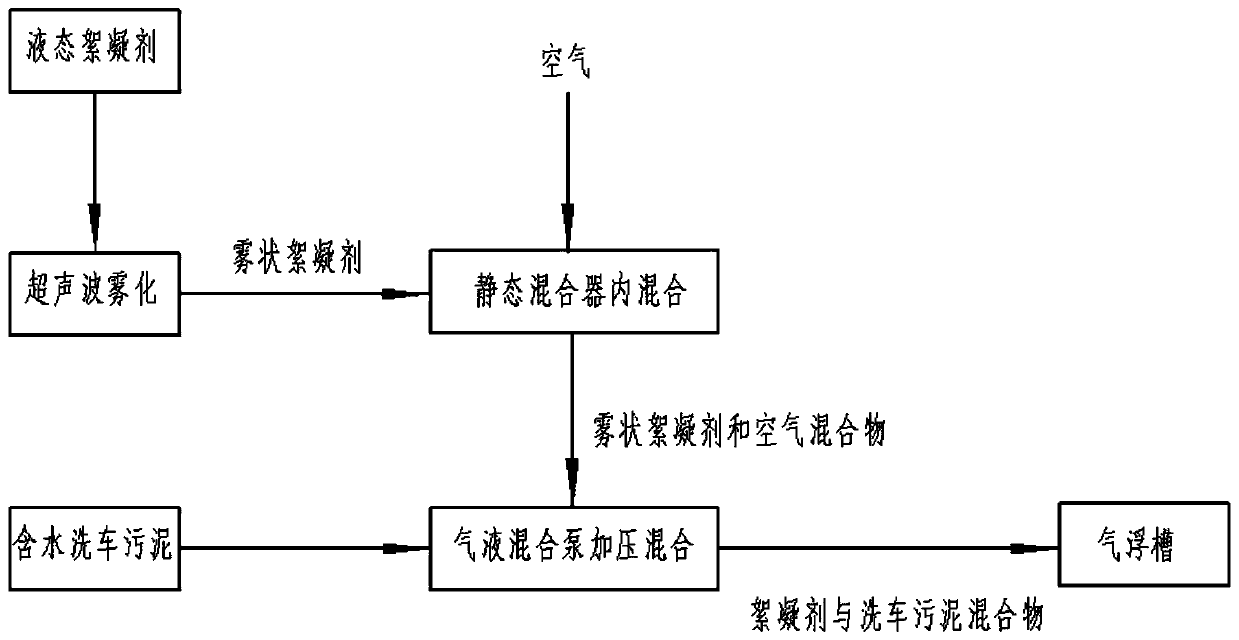

[0015] Specific implementation mode one: the method for mixing flocculant and motor vehicle cleaning sludge in this embodiment is carried out according to the following steps:

[0016] 1. Atomization of flocculant:

[0017] The liquid flocculant is atomized into mist flocculant by ultrasonic atomizer;

[0018] For the solid flocculant, first dissolve it with clean water into a liquid aqueous solution, and then use an ultrasonic atomizer to atomize it into a mist flocculant;

[0019] 2. Mixing of mist flocculant and air: place the spray port of the ultrasonic atomizer in a static mixer connected to the atmosphere, and mix the mist flocculant with air under normal pressure to obtain mist flocculant and air mixture;

[0020] 3. Mix the mixture obtained in step 2 with the water-containing car washing sludge by using a gas-liquid mixing pump under pressure.

[0021] Compared with the stirring mixing in the traditional flocculation tank, this method mixes the flocculant and car w...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the ultrasonic frequency of the ultrasonic nebulizer is 30-50 kHz. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in step 1, the ultrasonic frequency of the ultrasonic nebulizer is 40 kHz. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com