Semi-flexible anti-rut pavement material and preparation method thereof

A pavement material and anti-rutting technology, applied in the field of road rutting disposal, can solve problems such as insufficient crack resistance, and achieve the effects of reducing the risk of cracking, longer life, and better volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

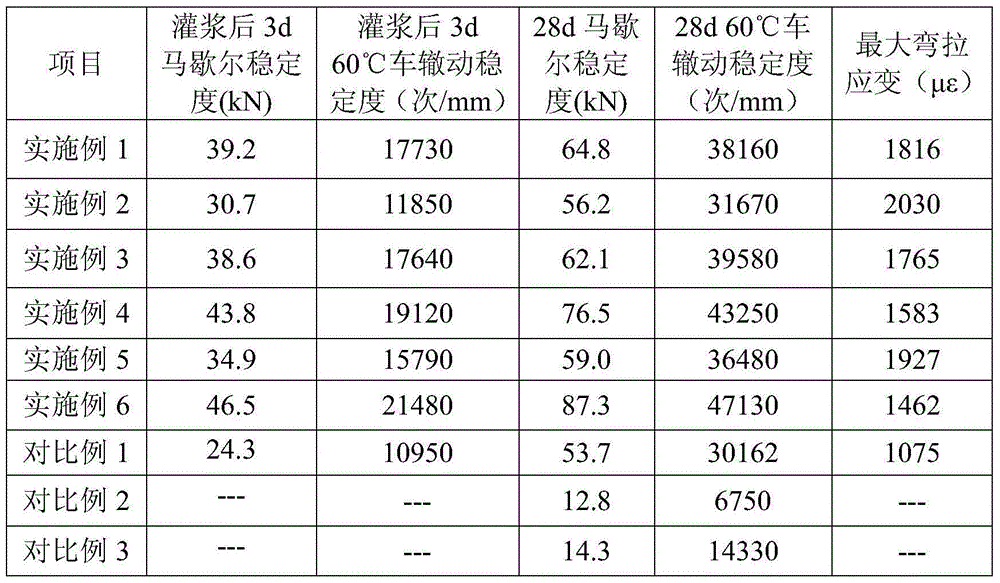

Examples

Embodiment 1

[0024] Preparation of large void cement-based mixture: firstly mix 42.5 grade sulphoaluminate cement, coarse aggregate, fine aggregate, water and powdered polycarboxylate superplasticizer in a weight ratio of 1:4:0.4:0.1:0.003 Mix and stir evenly, pave the mixed mixture with a thickness of 5cm, control the porosity of the porous mixture at about 27%, and maintain it for 4 hours before use.

[0025] Preparation of flexible grouting material: First, mix liquid epoxy resin and water-based epoxy curing agent in a weight ratio of 1:1, and keep stirring until the mixture is uniform to obtain a water-based epoxy resin emulsion for use; then mix each component The materials are weighed according to the following parts by weight and put into the mixing pot: 1 part of 42.5 grade Portland cement, 0.65 part of slow-cracking and fast-setting modified emulsified asphalt with a solid content of 50%, 0.35 part of water-based epoxy resin emulsion , 0 part of waste tire rubber powder, 0.0025 pa...

Embodiment 2

[0028] Preparation of large void cement-based mixture: firstly mix 42.5 grade sulphoaluminate cement, coarse aggregate, fine aggregate, water and powdered polycarboxylate superplasticizer in a weight ratio of 1:6:0.7:0.3:0 Mix and stir evenly, pave the mixed mixture, the thickness of the pavement is 12cm, control the porosity of the porous mixture at about 35%, and keep it for 4 hours before use.

[0029] Preparation of flexible grouting material: First, mix liquid epoxy resin and water-based epoxy curing agent at a weight ratio of 1:1.5, and keep stirring until the mixture is uniform to obtain a water-based epoxy resin emulsion for use; then mix each component The materials are weighed according to the following parts by weight and put into the mixing pot: 1 part of 42.5 grade Portland cement, 1 part of slow-cracking and fast-setting modified emulsified asphalt with a solid content of 65%, 0.1 part of water-based epoxy resin emulsion , 0.02 part of waste tire rubber powder, 0...

Embodiment 3

[0032] Preparation of large void cement-based mixture: first, 42.5 grade sulphoaluminate cement, coarse aggregate, fine aggregate, water and powdery naphthalene-based water reducer are carried out in a weight ratio of 1:5:1:0.15:0.006 Mix and stir evenly, pave the well-mixed mixture, the thickness of the pavement is 7cm, control the porosity of the porous mixture at about 31%, and keep it for 4 hours before use.

[0033] Preparation of flexible grouting material: First, mix liquid epoxy resin and water-based epoxy curing agent in a weight ratio of 1:1.2, and keep stirring until the mixture is uniform to obtain a water-based epoxy resin emulsion for use; then mix each component The materials were weighed according to the following parts by weight and put into the mixing pot: 1 part of 42.5 grade sulfoaluminate cement, 0.8 part of medium-cracking fast-setting modified emulsified asphalt with a solid content of 65%, 0.25 part of water-based epoxy resin emulsion 0.03 part of waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com