Environment-friendly type split mending material for polymer emulsion inorganic powder and nano material composite modified emulsified asphalt

A technology of inorganic powder materials and polymer emulsions, applied in building thermal insulation materials, building structures, solid waste management, etc. Simple, moderate strength, good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

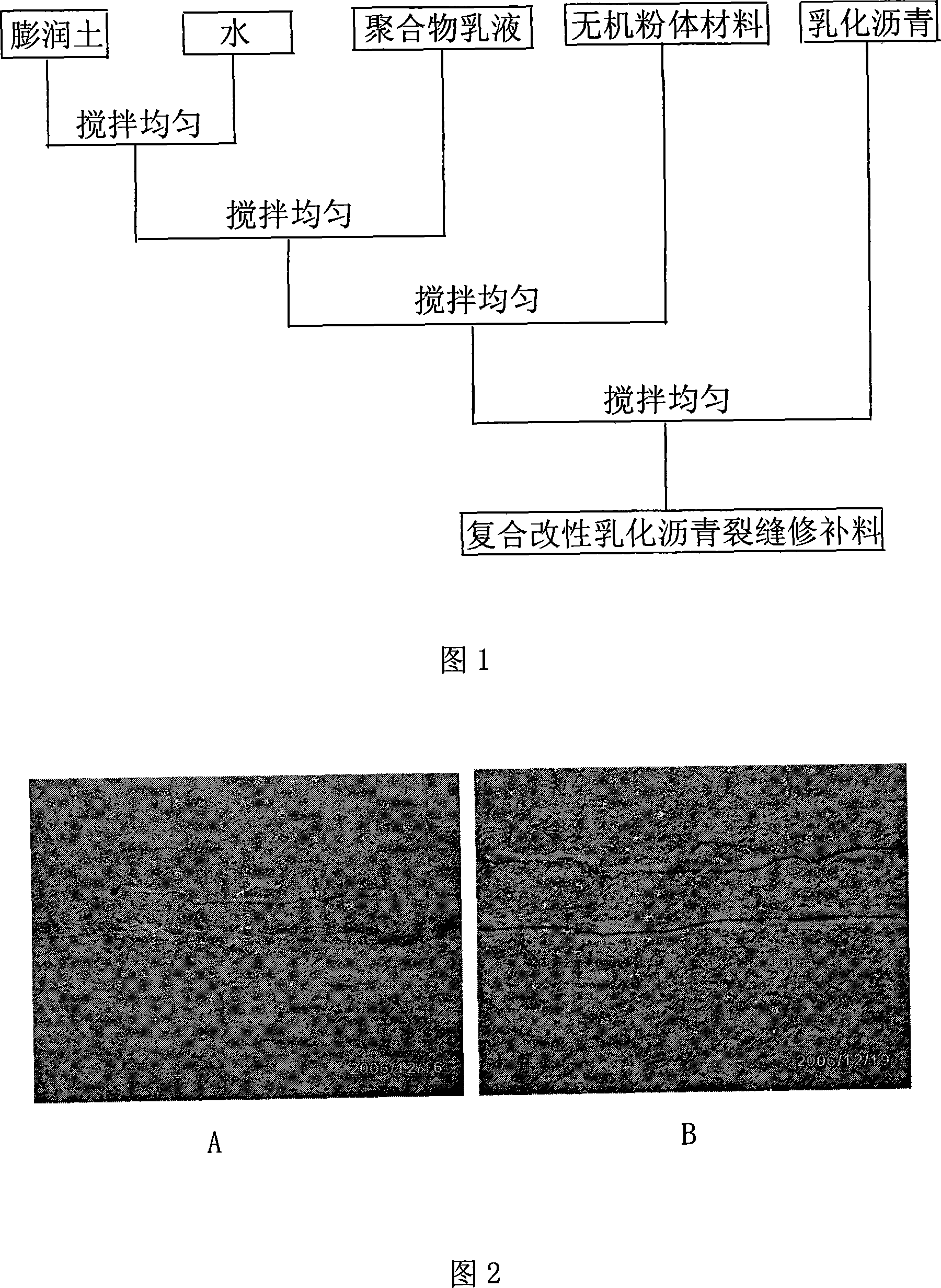

[0020] Embodiment 1: Composition and preparation of rigid pavement repair material:

[0021] Components and ratio (mass ratio): emulsified asphalt: inorganic powder material: nano silicon dioxide: acrylate emulsion: water = 50:70:7:25:50; wherein the inorganic powder material is composed of cement, bentonite, quartz The sand is mixed according to the mass ratio of 40:10:20.

[0022] Preparation process: Stir bentonite and water evenly, then add it to the acrylate emulsion and stir evenly, then add cement, quartz sand and nano-silica to the mixing system and stir evenly, and finally mix the material Slowly add all of it into the emulsified asphalt and stir evenly.

Embodiment 2

[0023] Embodiment 2: Composition and preparation of asphalt pavement repair material:

[0024] Components and ratio (mass ratio): emulsified asphalt: inorganic powder material: nano silicon dioxide: acrylate emulsion: water = 50:50:5:25:40, wherein the inorganic powder material is made of cement, bentonite, quartz The sand is mixed with a mass ratio of 30:10:10.

[0025] Preparation process: Stir bentonite and water evenly, then add it to the acrylate emulsion and stir evenly, then add cement, quartz sand and nano-silica to the mixing system and stir evenly, and finally mix the material Slowly add all of it into the emulsified asphalt and stir evenly.

Embodiment 3

[0026] Embodiment 3: Composition and preparation of building crack repair material:

[0027] Components and ratio (mass ratio): emulsified asphalt: inorganic powder material: nano silicon dioxide: acrylate emulsion: water = 35:50:1:25:45, wherein the inorganic powder material is made of cement, bentonite, quartz The sand is mixed according to the mass ratio of 25:8:17.

[0028] Preparation process: Stir bentonite and water evenly, then add it to the acrylic emulsion and stir evenly, then add cement and quartz sand to the mixing system and stir evenly, and finally slowly add all the materials that have been stirred evenly to the emulsified asphalt Mix well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com