Method for preparing tailing micro-aggregate and simultaneously producing magnetite

A technology of magnetite and tailings, applied in the direction of iron oxide/hydroxide, etc., can solve the problems of destroying the performance of cemented materials, flooding the surface of cemented materials, polluting the surface of cemented materials, etc., to reduce environmental pollution, Improved volume stability and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

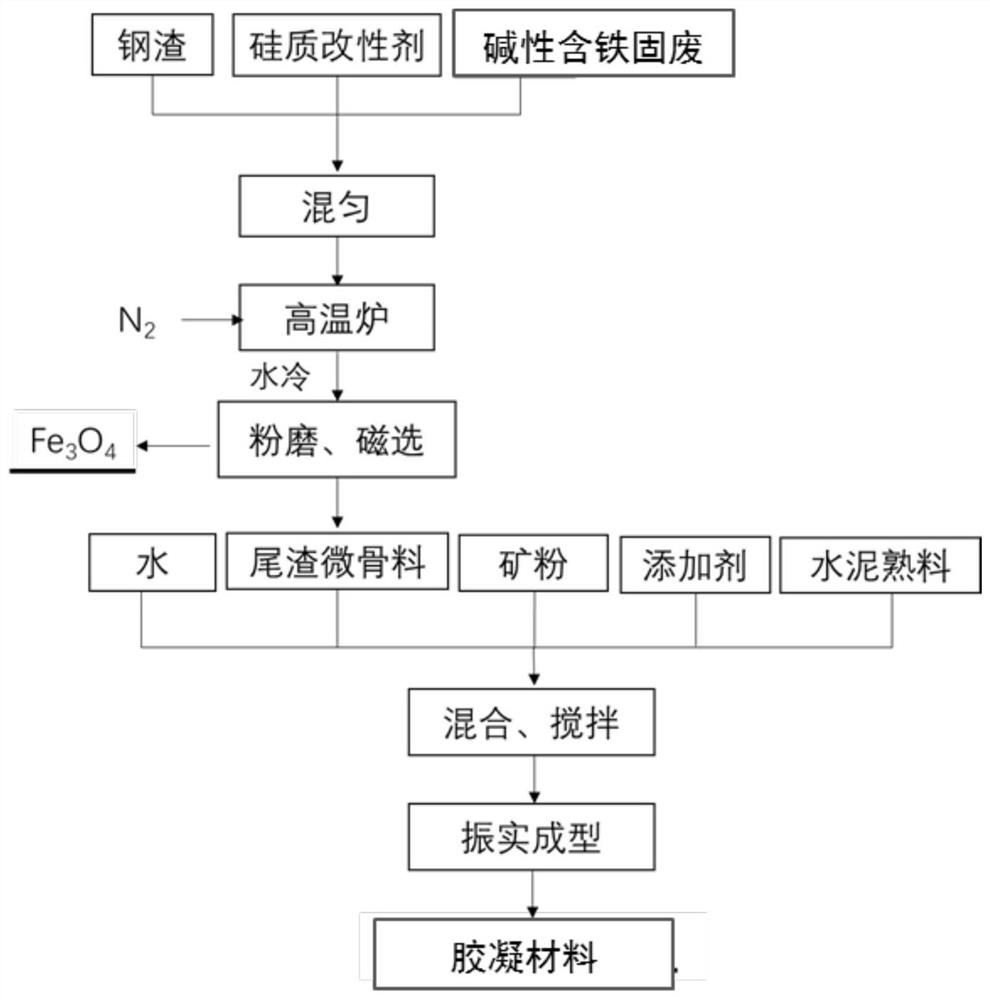

[0046] S1: Take 60 parts of steel slag, 20 parts of red mud, and 20 parts of fly ash and mix them evenly. The basicity of the mixture (CaO / SiO 2 The mass ratio) is 1.05, the mixture is ground to 150 mesh, and the mixture block is obtained by the pressure molding of 20MPa;

[0047] S2: use a heavy alumina crucible, put it into a high temperature box muffle furnace, heat the mixture to 1500°C under a nitrogen protective atmosphere to completely melt the mixture, the heating rate is 10°C / min, calcined for 30min, and then cooled to 1250°C ℃, the cooling rate is 15℃ / min, and the temperature is kept for 40min;

[0048] S3: Take out the sample and put it in water to cool to room temperature, then put the sample into a blast drying oven and dry it at 105°C for 24 hours, crush the dried sample, and grind it with a cement mill for 25 minutes to 50 mesh;

[0049] S4: The ground powder is subjected to magnetic separation with a magnetic separation tube, the magnetic field strength is 0.1...

preparation example 2

[0051] The method and raw materials are the same as those of Preparation Example 1, except that the difference lies in step S1, specifically: take 60 parts of steel slag, 30 parts of red mud, and 10 parts of fly ash, and mix them evenly, and the mixture alkalinity (CaO / SiO) 2 The mass ratio) was 1.24, the mixture was ground to 150 mesh, and the mixture block was obtained by pressure molding at 20 MPa.

preparation example 3

[0053] The method and raw materials are the same as those of Preparation Example 1, the difference is only in step S1, specifically: take 40 parts of steel slag, 40 parts of red mud, and 20 parts of fly ash and mix well, and the mixture alkalinity (CaO / SiO) 2 The mass ratio) was 0.81, the mixture was ground to 150 mesh, and the mixture block was obtained by pressure molding at 20 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com