Patents

Literature

44results about How to "Pollution fit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microorganism composite bacterial agent for restoration of saline alkali soil polluted by petroleum

InactiveCN102453678ANo secondary pollutionPollution fitBacteriaContaminated soil reclamationAlkali soilBacillus megaterium

The invention relates to a microorganism composite bacterial agent applicable to the restoration of saline alkali soil polluted by petroleum, and a preparation method thereof, and belongs to the technical field of environment protection. The bacterial agent mainly comprises the following 3 components: composite microorganism bacterial liquid, nutrients, and a surfactant. The composite microorganism bacterial liquid is obtained by performing liquid culture of 3 petroleum hydrocarbon degrading bacteria of bacillus megaterium P9 strains (with a preservation number of CGMCC No. 4270), pseudomonas sp. P4 strains (with a preservation number of CGMCC No. 4269), and achromobacter xylosoxidans P2 strains (with a preservation number of CGMCC No. 4268) to obtain microorganism bacterial strains, and mixing the strains with the nutrients. The bacterial strains are preserved at China microorganism strain preservation management committee general microbiological center. The composite microorganism bacterial liquid, the nutrients and the surfactant are mixed according to a ratio of 30-200:1-2:0.2-0.5 so as to obtain the microorganism composite bacterial agent. The microorganism composite bacterial agent prepared by the invention has high removing efficiency for petroleum pollution in saline alkali soil, can both reduce the pH value of the saline alkali soil, and improve soil physical and chemical properties.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

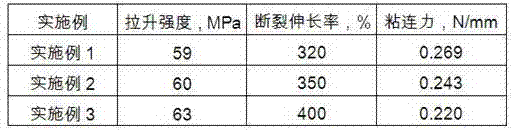

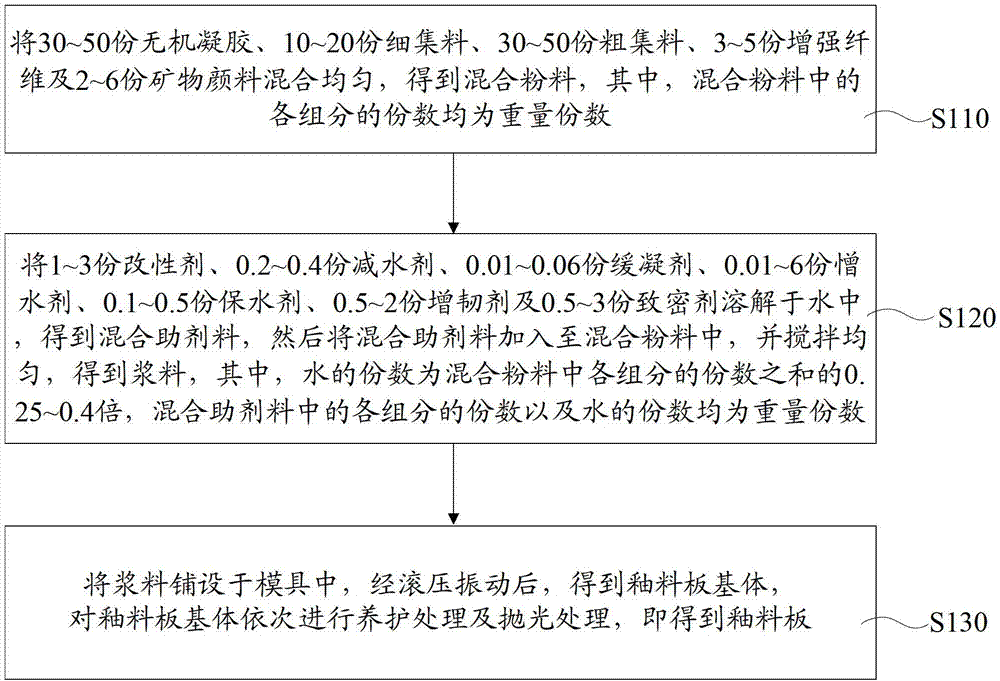

Glaze material and preparation method of glaze material plate

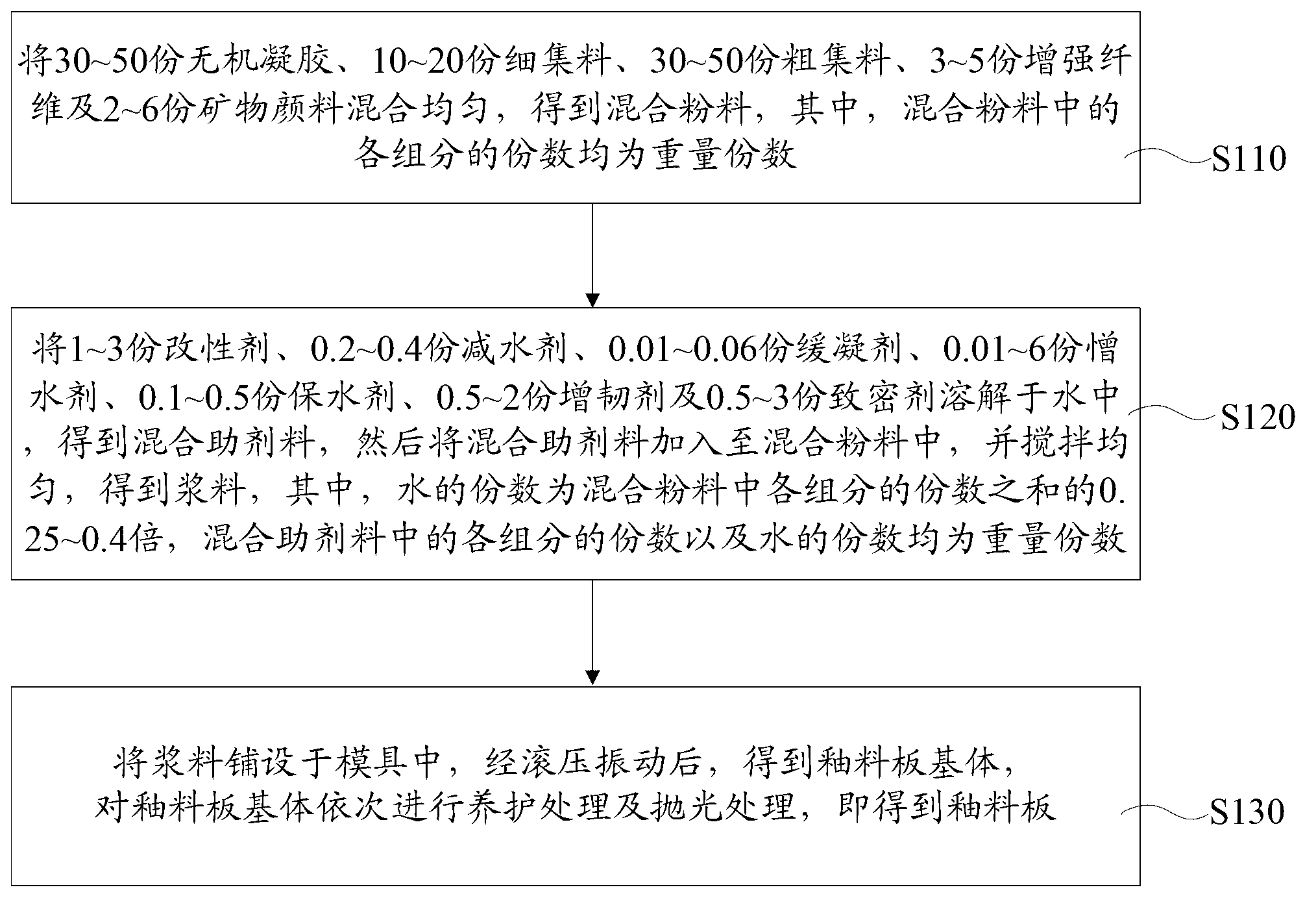

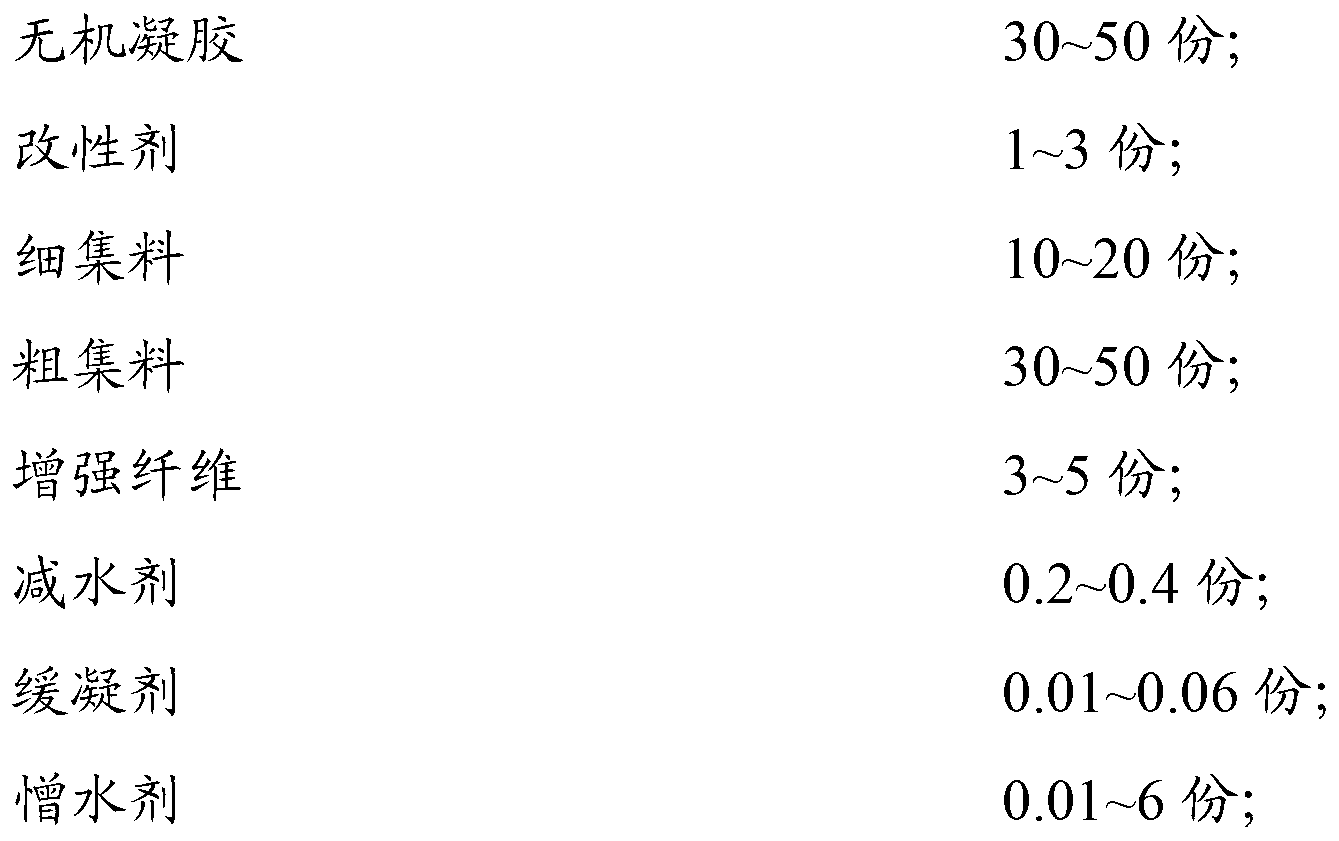

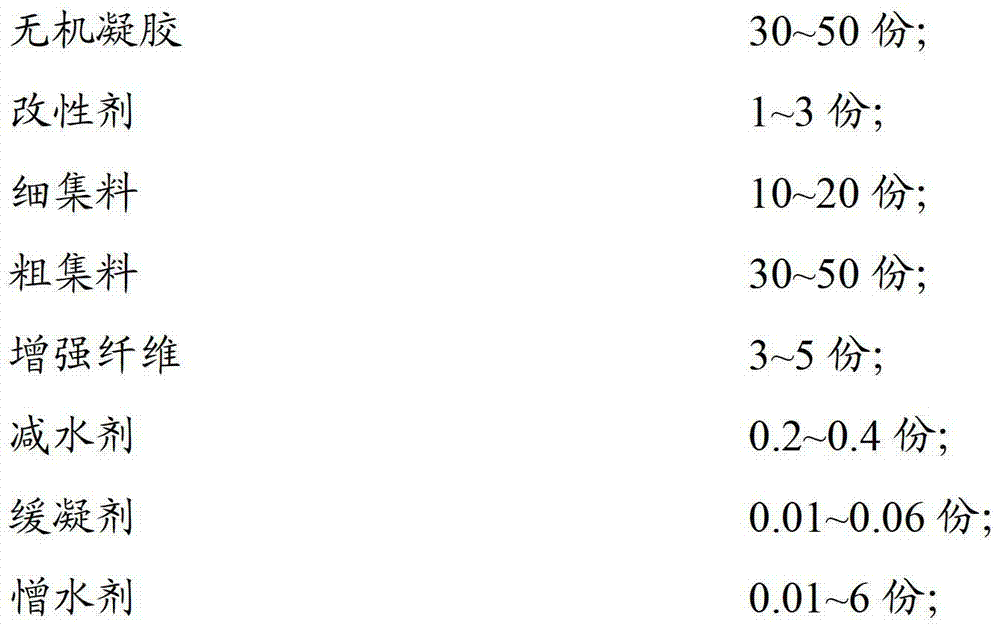

The invention relates to a glaze material which comprises the following components in parts by weight: 30-50 parts of inorganic gel, 1-3 parts of modifier, 10-20 parts of fine aggregate, 30-50 parts of coarse aggregate, 3-5 parts of reinforced fiber, 0.2-0.4 part of water reducer, 0.01-0.06 part of retarder, 0.01-6 parts of moisture repellent, 0.1-0.5 parts of water-retaining agent, 0.5-2 parts of flexibilizer, 0.5-3 parts of densification agent and 2-6 parts of mineral pigment. The invention also provides a preparation method of a glaze material plate. Most of the components of the glaze material are common inorganic materials, thus being low in cost, having no toxicity and radiation, having no contamination, and being environment-friendly. When in preparation of the glaze material plate by using the glaze material, the step of high temperature roasting is eliminated, the molded glaze material plate can be cured at normal temperature, and carbon emission can be greatly reduced, so that the preparation method is environment-friendly and energy-saving.

Owner:深圳市爱思宝科技发展有限公司

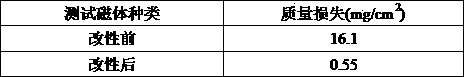

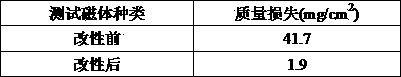

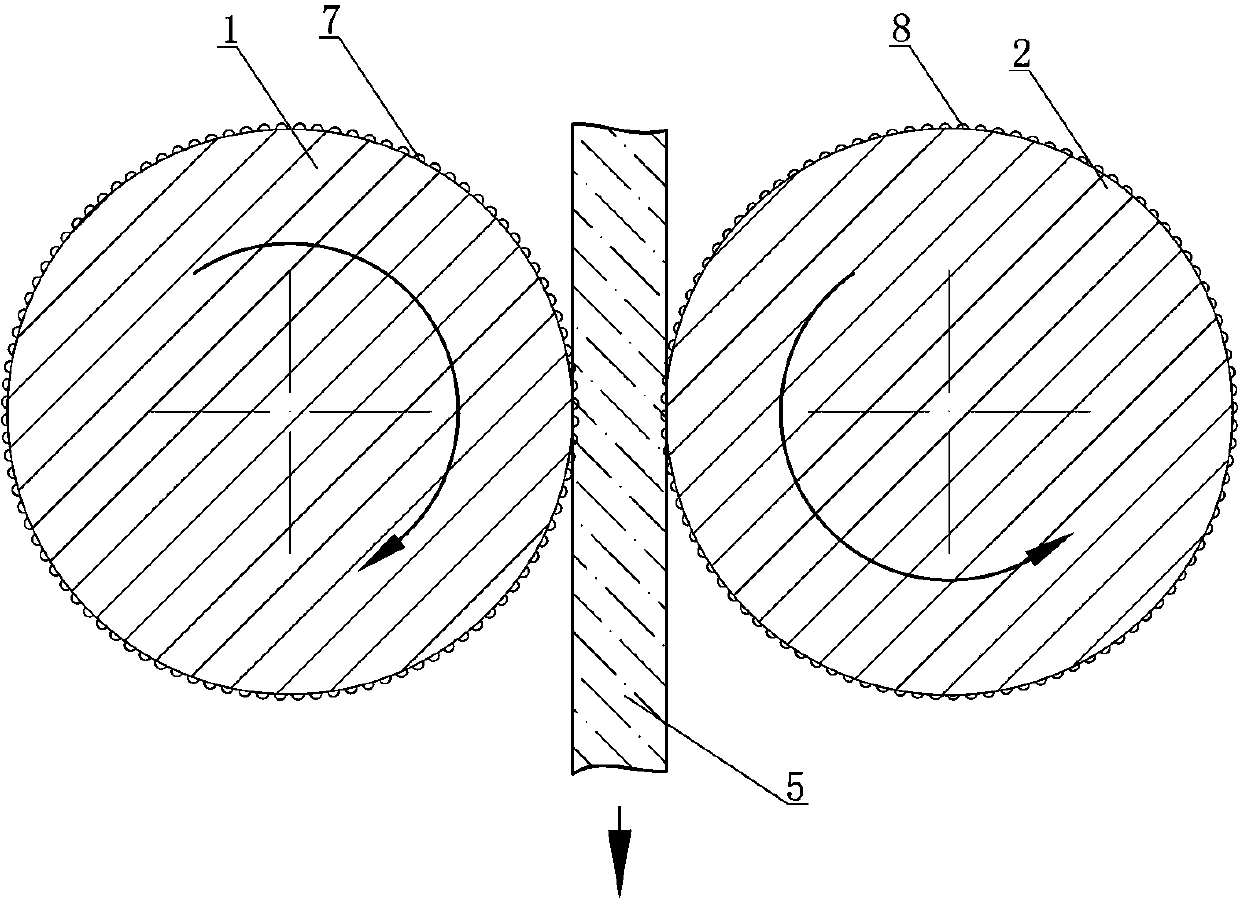

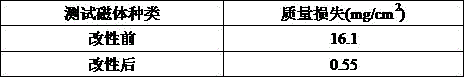

Method for improving corrosion resistance of sintered neodymium iron boron magnet

ActiveCN103668178ALittle influence on magnetic propertiesChange structureInductances/transformers/magnets manufactureMetallic material coating processesIrradiationGrain boundary

The invention discloses a method for improving the corrosion resistance of a sintered neodymium iron boron magnet, and relates to a permanent magnet material surface modification technology. The method mainly comprises the following steps: 1, carrying out sanding, polishing, cleaning and drying pretreatment of a sintered neodymium iron boron magnet surface for processing; 2, clamping the above obtained pretreated sintered neodymium iron boron magnet on a workbench; 3, carrying out laser irradiation of the sintered neodymium iron boron magnet surface for processing under the protection of vacuum or a gas until a grain boundary phase melts to form a micro melting pool; 4, sending metal or compound nano-powder into the grain boundary micro melting pool through a powder sending device for the micro-alloying of the nano-powder and the grain boundary phase; and 5, cleaning up unalloyed nano-powder to obtain a sintered neodymium iron boron magnet with a selectively alloying modified surface grain boundary. The method can effectively change the component and structure of the magnet surface grain boundary phase, can improve the physical and chemical properties of the grain boundary phase, can inhibit the intercrystalline corrosion of the surface of the magnet, and can substantially improve the corrosion resistance of the magnet. The method has the advantages of simple process, easy operation, and suitableness for the large-scale batch production.

Owner:东台城东科技创业园管理有限公司

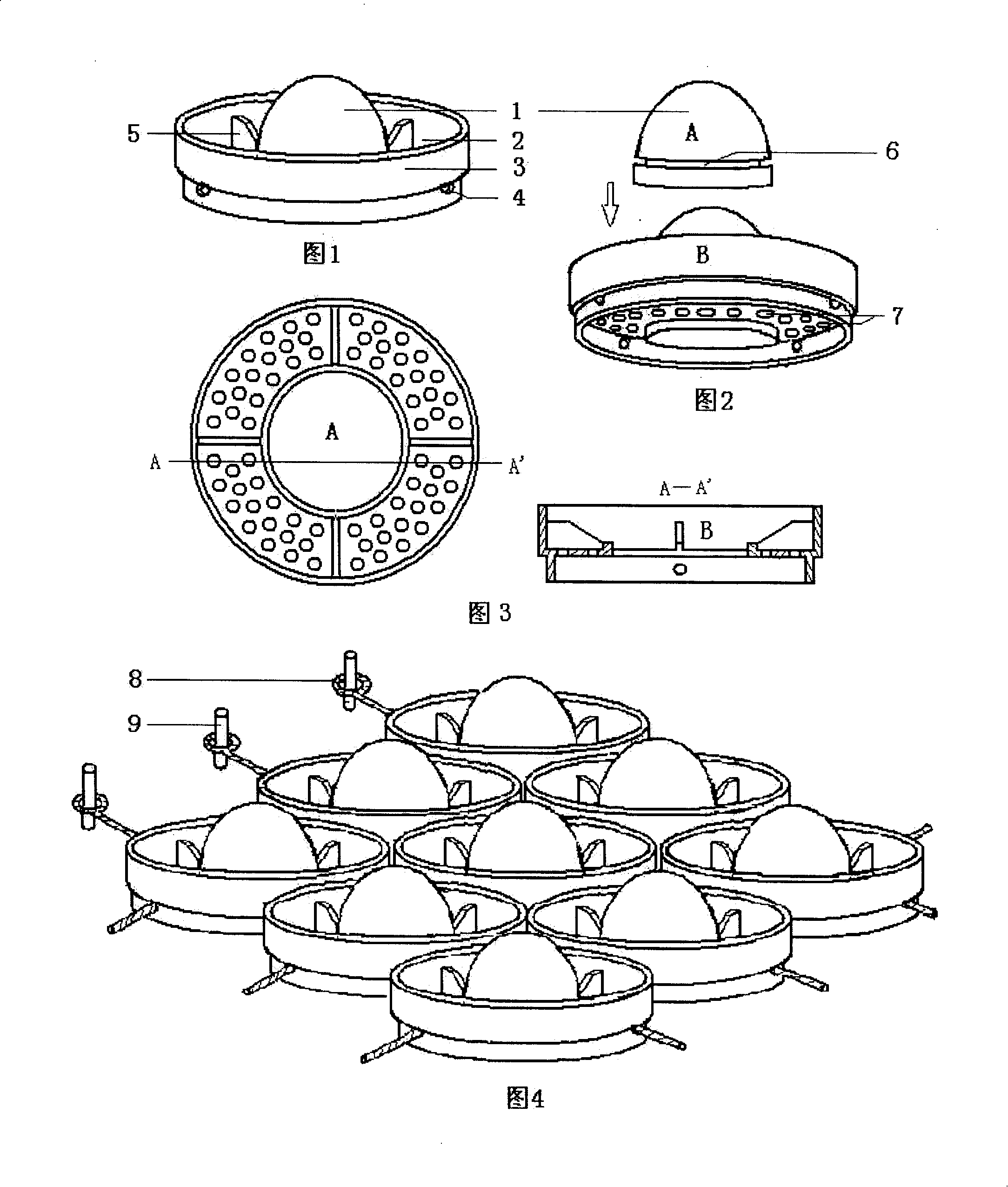

Soft plant floating bed for protecting bank and purifying water

InactiveCN101190813AExtended service lifeLow costProtective foundationBiological water/sewage treatmentIn situ remediationWater level rise

The invention relates to a soft plant floating bed which is applied in revetment and water purification, which is a composite plant cultivation apparatus on water that adopts a disk-shaped single floating bed as one unit, wherein, a plurality of hygrophytes or amphiphytes are cultivated in the floating bed to form a floating bed that can float in the water; meanwhile, the aim of in-situ remediation and the control of the eutrophic water can be reached by using the plant to provide the biological cleaning function on the eutrophic water in lakes, rivers and channels. The main characteristics or effects of the floating bed are that: 1. the invention is used for acting the biological purification on eutrophic water in different waters; 2. one end of the floating bed is fixedly connected to the bank, which provides protection to the hydro-fluctuation belt and bank of reservoirs, lakes, rivers and channels. When the water level rises, the plant in the floating bed which grows on the water can absorbs the water nutrition enrichment to decrease the eutrophication degree; when the water level decreases, the floating bed covers the hydro-fluctuation belt to provide wave absorption and a protection layer for the bank.

Owner:HUBEI UNIV

Pollution controlling method in cultivating nostoc and nostoc commune

InactiveCN1544612AQuality assuranceNo adverse effect on growthUnicellular algaeClimate change adaptationPlanktonPhacus

The invention discloses a control method of pollution of nostoc and agaric culture mediums, firstly adopting pure cultivation in the strain production; secondly, before inoculating, washing culture tank and container; thirdly, washing or screening algae; fourthly, filtering the culture solution by gauze; fifthly, killing or eliminating planktons. It has simple and easy operation, high efficiency, convenient operation, low cost, able to effectively control the quantities of living pollutants in the culture solution within 1% during cultivating, and suitable to control production pollution in factories.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Modified polyvinyl alcohol packaging film and preparation method thereof

The invention provides a modified polyvinyl alcohol packaging film, and relates to the technical field of a film packaging material. The modified polyvinyl alcohol packaging film is prepared from the following ingredients in parts by weight: 5 to 50 parts of polyvinyl alcohol resin, 15 to 25 parts of starch, 0.05 to 0.3 part of nano-zinc oxide, 0.5 to 5 parts of SiO2, 0.8 to 6 parts of antiblocking agents, 0.05 to 3 parts of tween-80, 0.02 to 4 parts of coupling agents, 0.5 to 9 parts of plasticizing agents, 0.1 to 0.4 part of antioxidants, 0.05 to 0.5 part of boracic acid, 0.01 to 0.1 part of defoaming agents and 40 to 100 parts of de-ionized water. The invention also provides a preparation method of the modified polyvinyl alcohol packaging film. The prepared modified polyvinyl alcohol packaging film has the advantages that adhesion cannot easily occur; the tensile intensity, the modulus and the thermal stability are good.

Owner:苏州泰如新材料科技有限公司

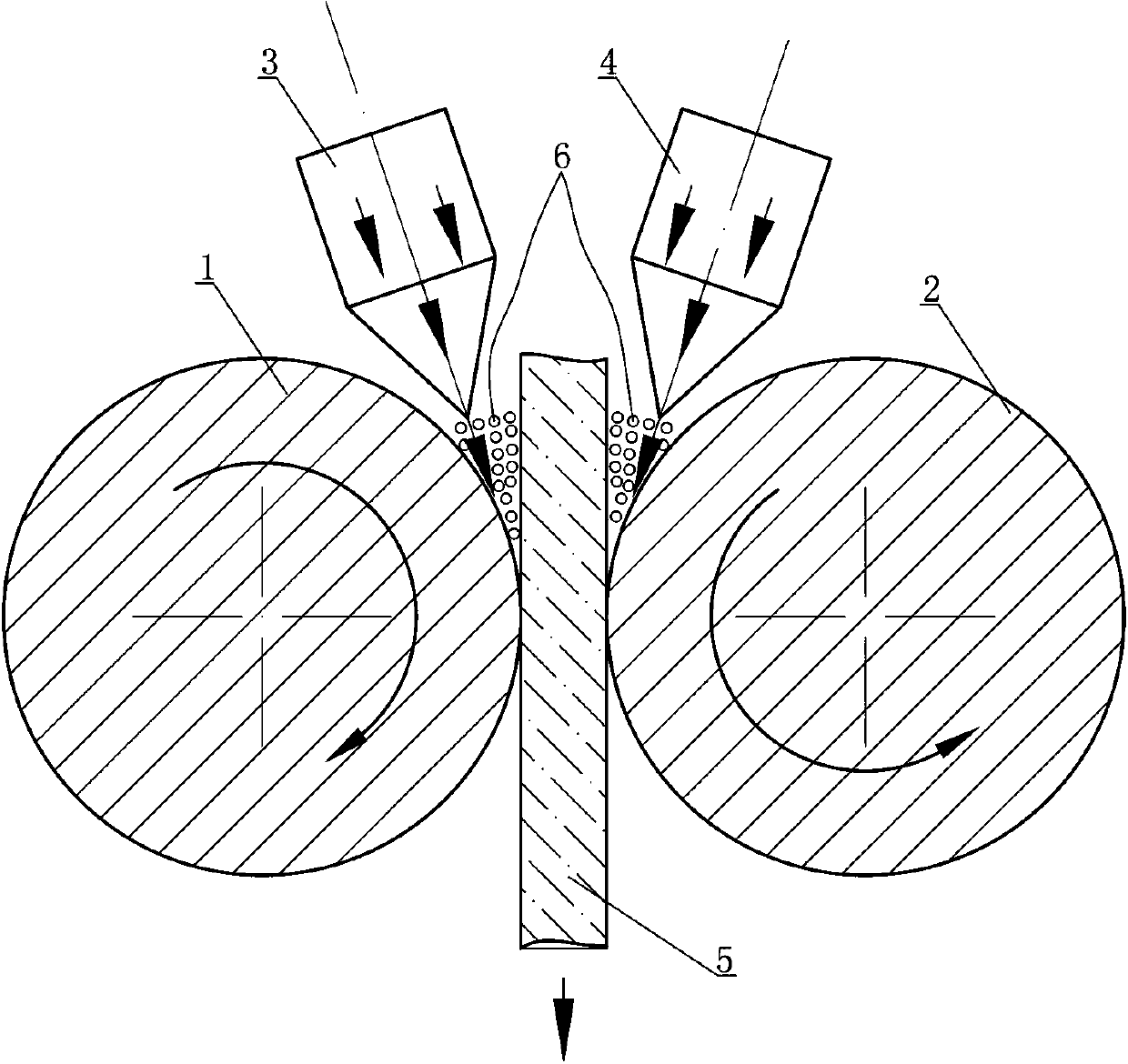

Concave pit lithium ion battery current collector as well as manufacturing method and equipment of concave pit lithium ion battery current collector

ActiveCN103811768AIncreased adhesion areaNo pollution in the processElectrode carriers/collectorsCurrent collectorEngineering

The invention provides a concave pit lithium ion battery current collector as well as a manufacturing method and equipment of concave pit lithium ion battery current collector. The manufacturing method comprises the following steps: filling the part between the current collector and a leftward roller with grains with the rigidity which is greater than that of a current collector material by a leftward sand filling hopper above the leftward roller when the current collector passes through a rolling station between the leftward roller and a rightward roller; extruding by the leftward roller to form a left concave pit in one side of the current collector by the grains; or / and filling the part between the current collector and the rightward roller with the grains with the rigidity which is greater than that of the current collector material by a rightward sand filling hopper above the rightward roller; and extruding by the rightward roller to form a right concave pit in one side of the current collector by the grains. According to the concave pit lithium ion battery current collector as well as the manufacturing method and equipment of of the current collector, the contact face between an active material of the concave pit lithium ion battery current collector and the surface of the current collector is enlarged and the surface sticking area between the active material and the current collector is enlarged, so that the adhesion strength is easy to enhance and the contact conductivity is improved; a process for manufacturing the concave pit lithium ion battery current collector by using a sand filling and rolling method is simple and is suitable for large-scale industrial production.

Owner:深圳市旭然电子有限公司

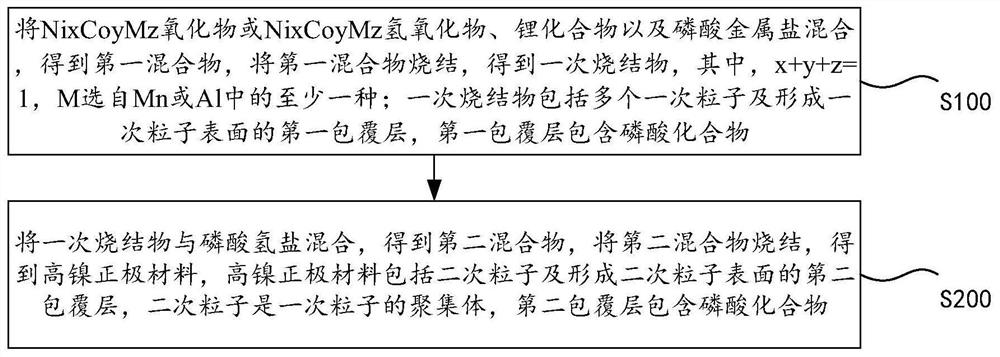

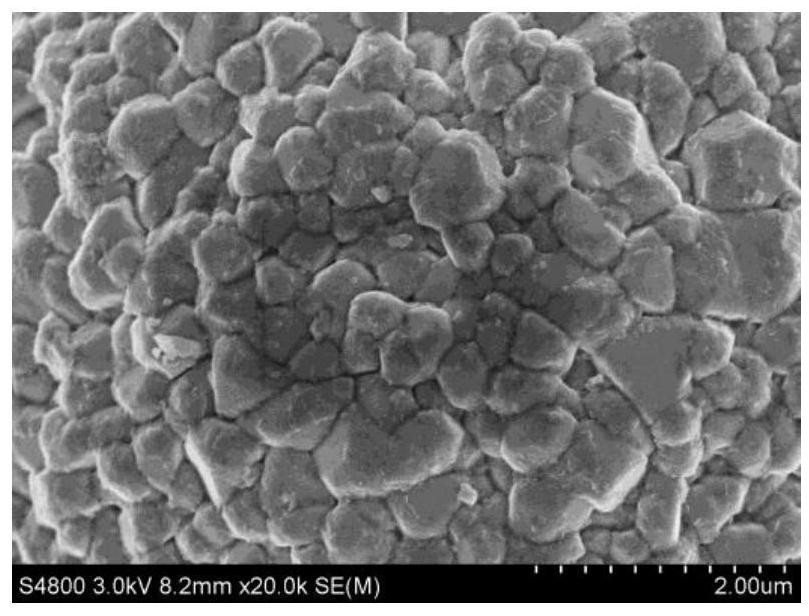

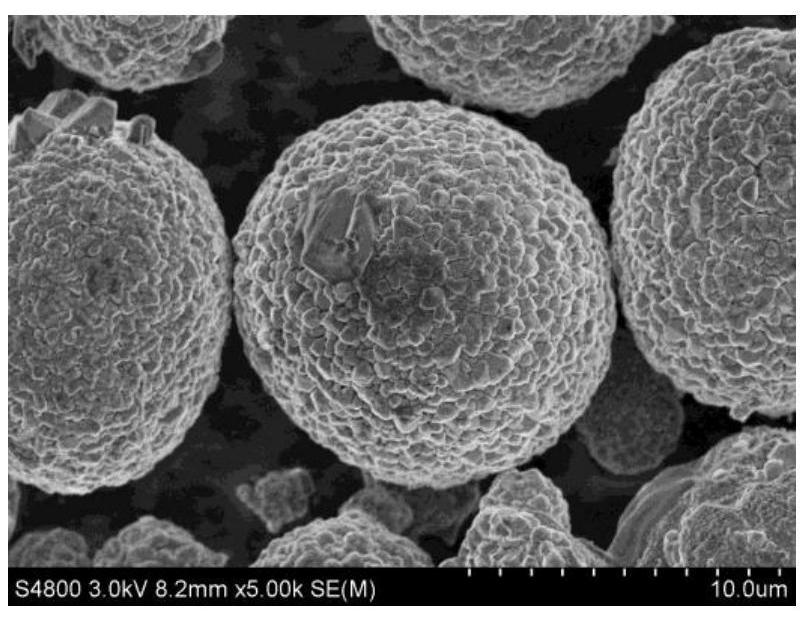

High-nickel positive electrode material, preparation method thereof and lithium ion secondary battery

ActiveCN112382741AReduce surface residual alkaliImprove thermal stabilityElectrode thermal treatmentSecondary cellsPhosphoric acidCyclic stability

The invention relates to the field of positive electrode materials, and provides a high-nickel positive electrode material, a preparation method thereof, and a lithium ion secondary battery. The high-nickel positive electrode material comprises secondary particles, wherein the secondary particles comprise a plurality of primary particles, the primary particles comprise an active substance, the general chemical formula of the active substance is LibNixCoyMzNwO2, 0.95 <=b <=1.05, 0.8 <=x < 1, 0<y+z<=0.2, x+y+z=1, 0.0001<=w<=0.003, M is selected from at least one of Mn and Al, and N is a metal; acoating layer which comprises a first coating layer and a second coating layer, wherein the first coating layer is formed on the surface of the primary particle, the second coating layer is formed onthe surface of the secondary particle, and each of the first coating layer and the second coating layer contains a phosphoric acid compound. According to the high-nickel positive electrode material,the preparation method thereof and the lithium ion secondary battery, the cost is low, large-scale production can be realized, and the rate capability and the cycling stability of the lithium batterycan be effectively improved.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Environment-friendly biomass particle fuel and processing method

The invention relates to the technical field of biomass fuel and specifically relates to environment-friendly biomass particle fuel and a processing method. The particle fuel is prepared from the following raw materials in parts by weight: 45 to 65 parts of woodwork waste mixture, 10 to 20 parts of mulberry stalk, 5 to 15 parts of straw, 5 to 8 parts of tobacco stem, 3 to 5 parts of flame accelerator, 2 to 3 parts of anti-slagging agent and 1 to 2 parts of sulfur fixing agent. The invention further discloses the processing method of the particle fuel. The processing method comprises the steps of preparing the flame accelerator, the anti-slagging agent and the sulfur fixing agent according to selected parts by weight; mixing and smashing; drying: drying an obtained wood pellet mixture at high temperature; extrusion forming: sending the dried solid fuel into a granulator to be extruded and granulated and finally cooling to obtain the environment-friendly biomass particle fuel. The environment-friendly biomass particle fuel and the processing method disclosed by the invention have reliable performance, and the environment-friendly biomass particle fuel can meet the requirement of energy conservation and environmental friendliness and meanwhile has long combustion time and high combustion ratio.

Owner:云南省福仑木业有限公司

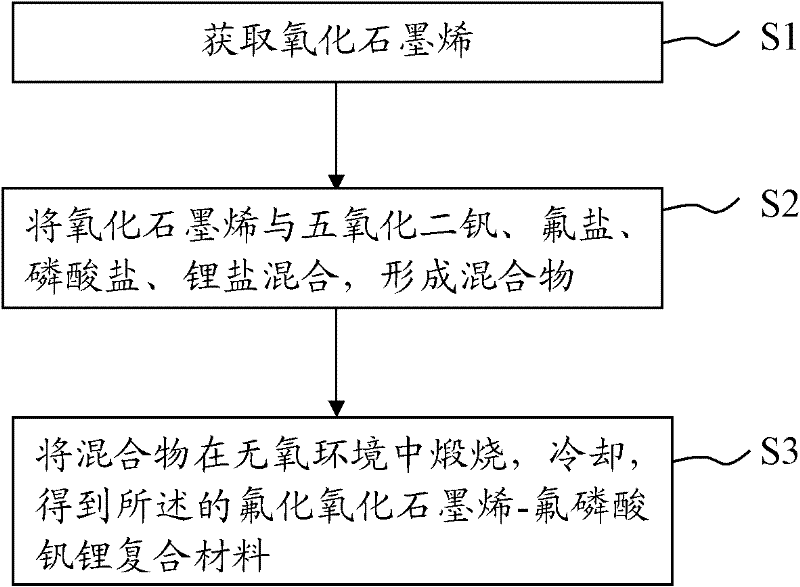

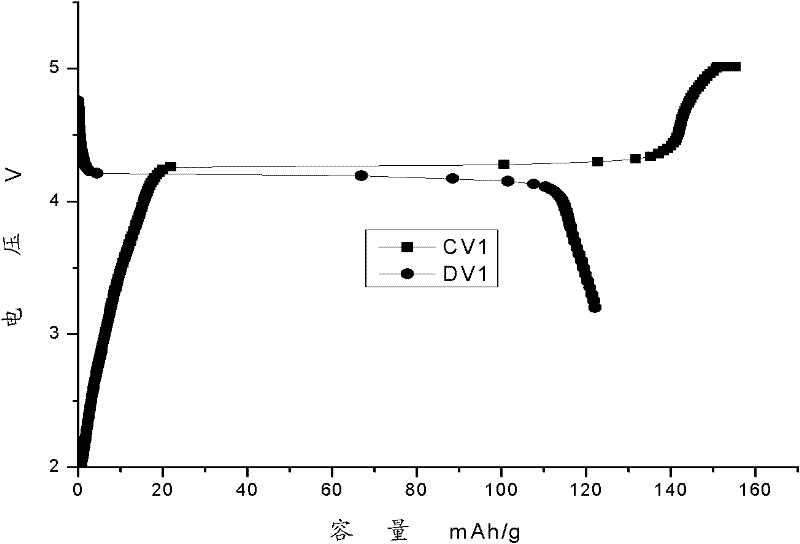

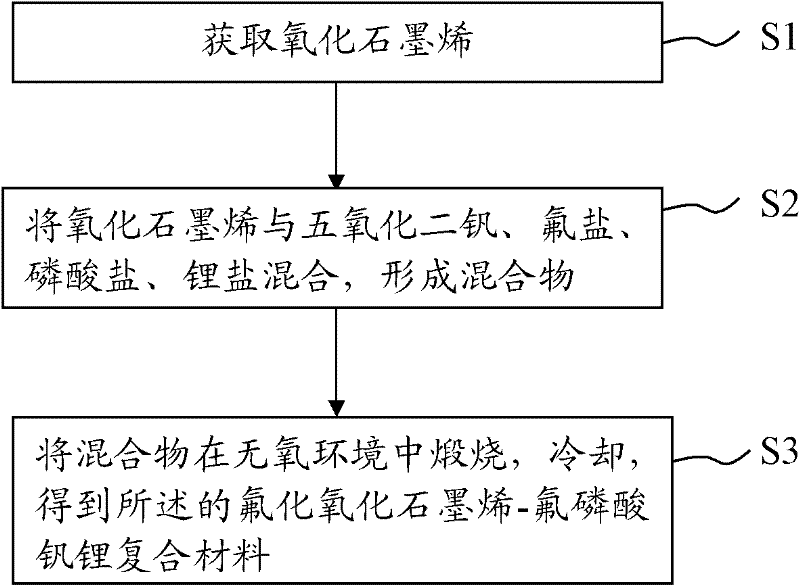

Fluorinated graphene oxide-lithium vanadium fluorophosphate composite material as well as preparation method and applications thereof

ActiveCN102544443AStable structure and performanceImprove conductivityCell electrodesPhosphateOxygen

The invention discloses a fluorinated graphene oxide-lithium vanadium fluorophosphate composite material as well as a preparation method and applications thereof.. The preparation method of the fluorinated graphene oxide-lithium vanadium fluorophosphate composite material comprises the following steps of obtaining graphene oxide; mixing the graphene oxide with vanadium pentoxide, villiaumite, phosphate and lithium salt to form a mixture; roasting the mixture in an oxygen-free environment, and cooling to obtain the fluorinated graphene oxide-lithium vanadium fluorophosphate composite material. The preparation method of the fluorinated graphene oxide-lithium vanadium fluorophosphate composite material is simple in process, low in cost, free from pollution and suitable for industrial production. The fluorinated graphene oxide-lithium vanadium fluorophosphate composite material prepared by using the method has a stable structure performance and high electric conductivity, and is high in power density when being used for preparing a lithium ion battery or / and anode materials of a capacitor.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

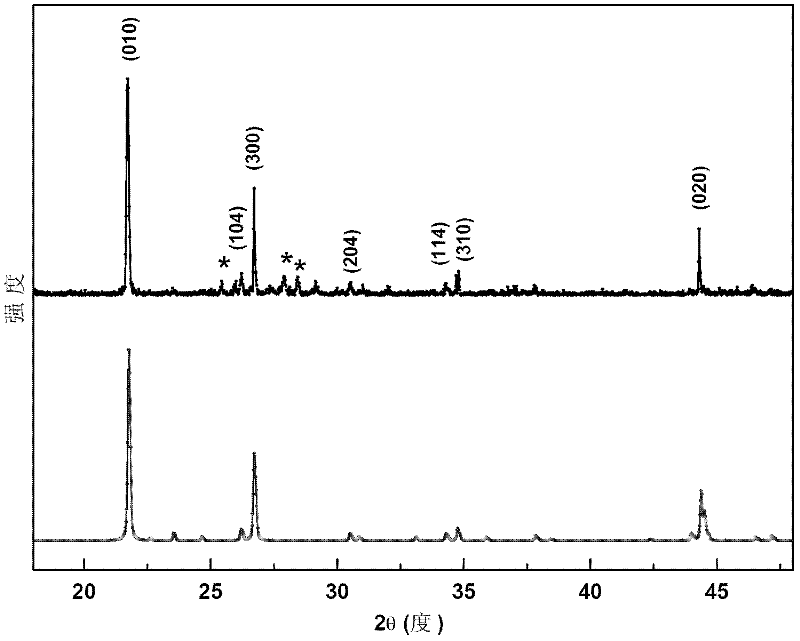

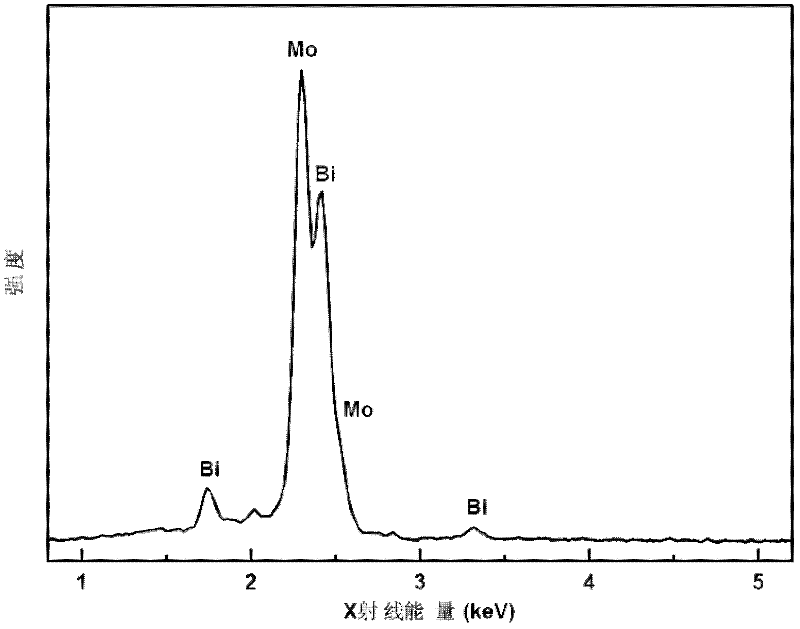

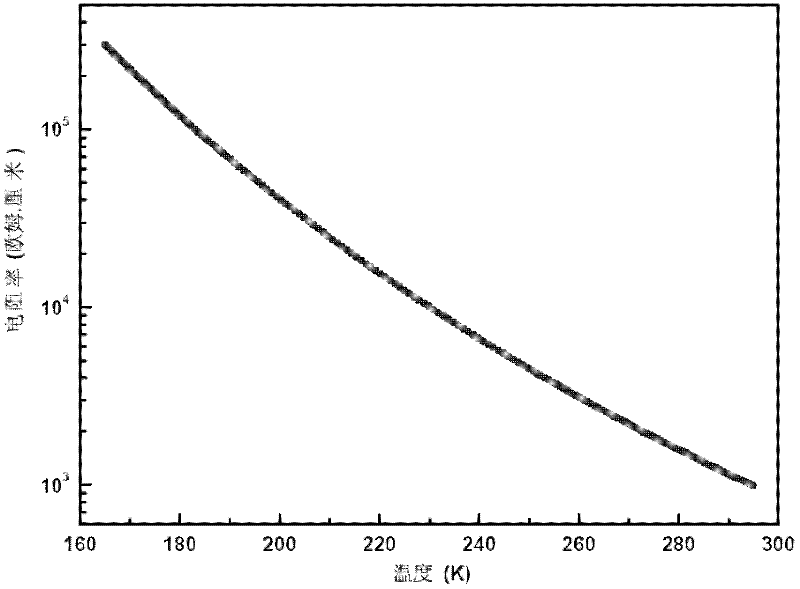

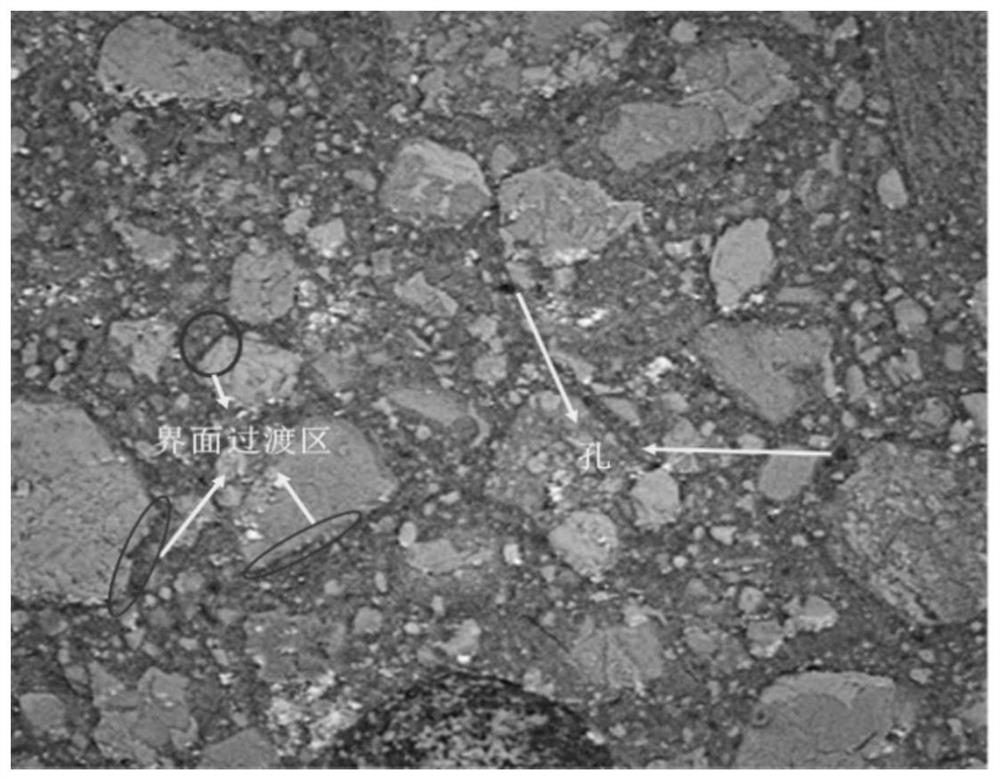

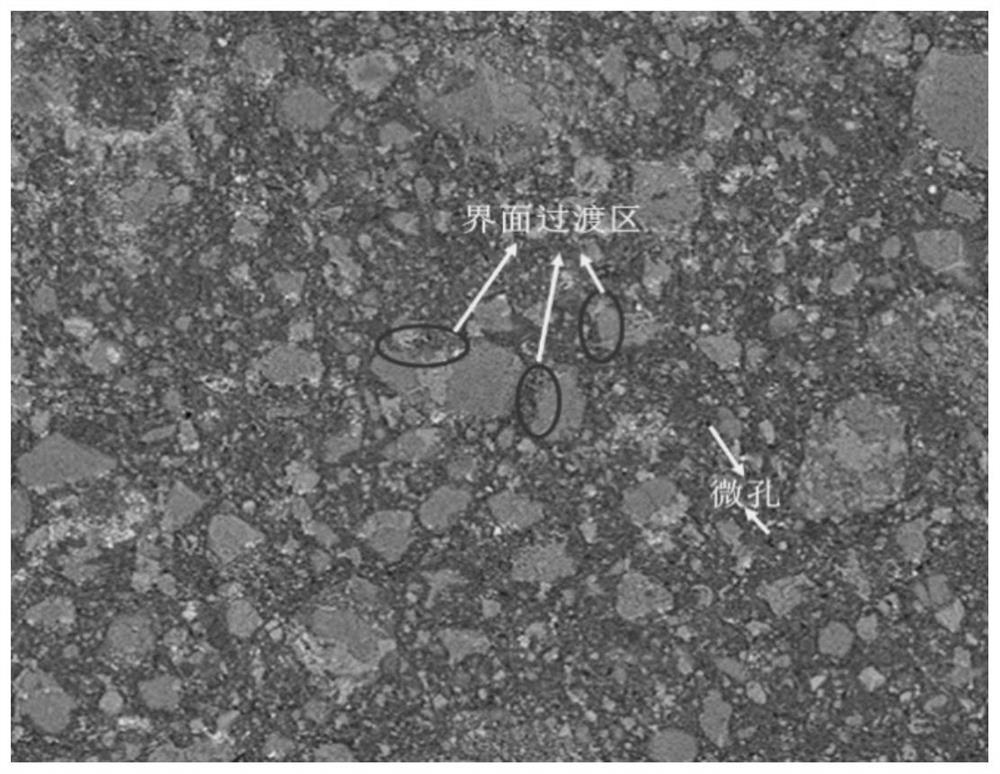

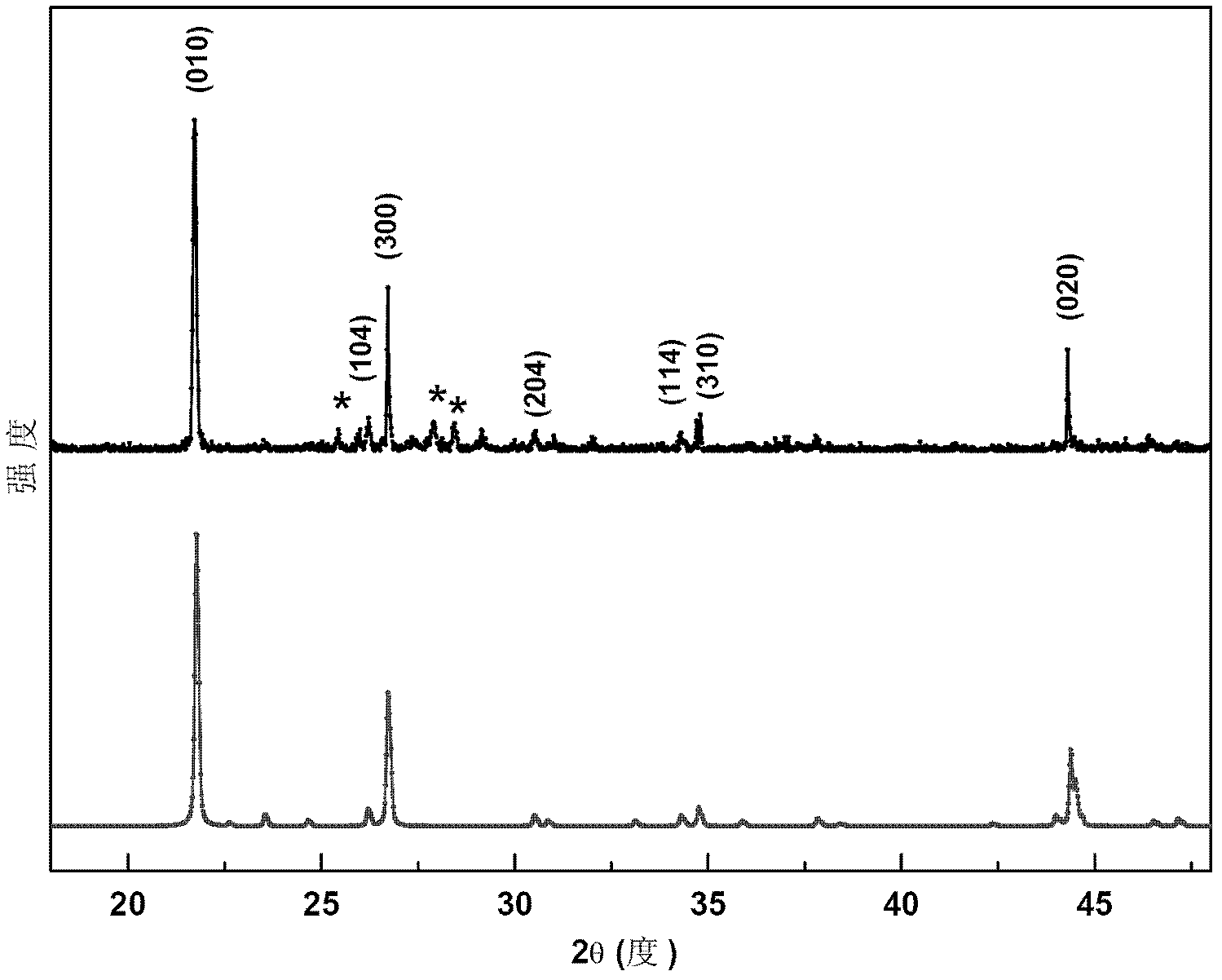

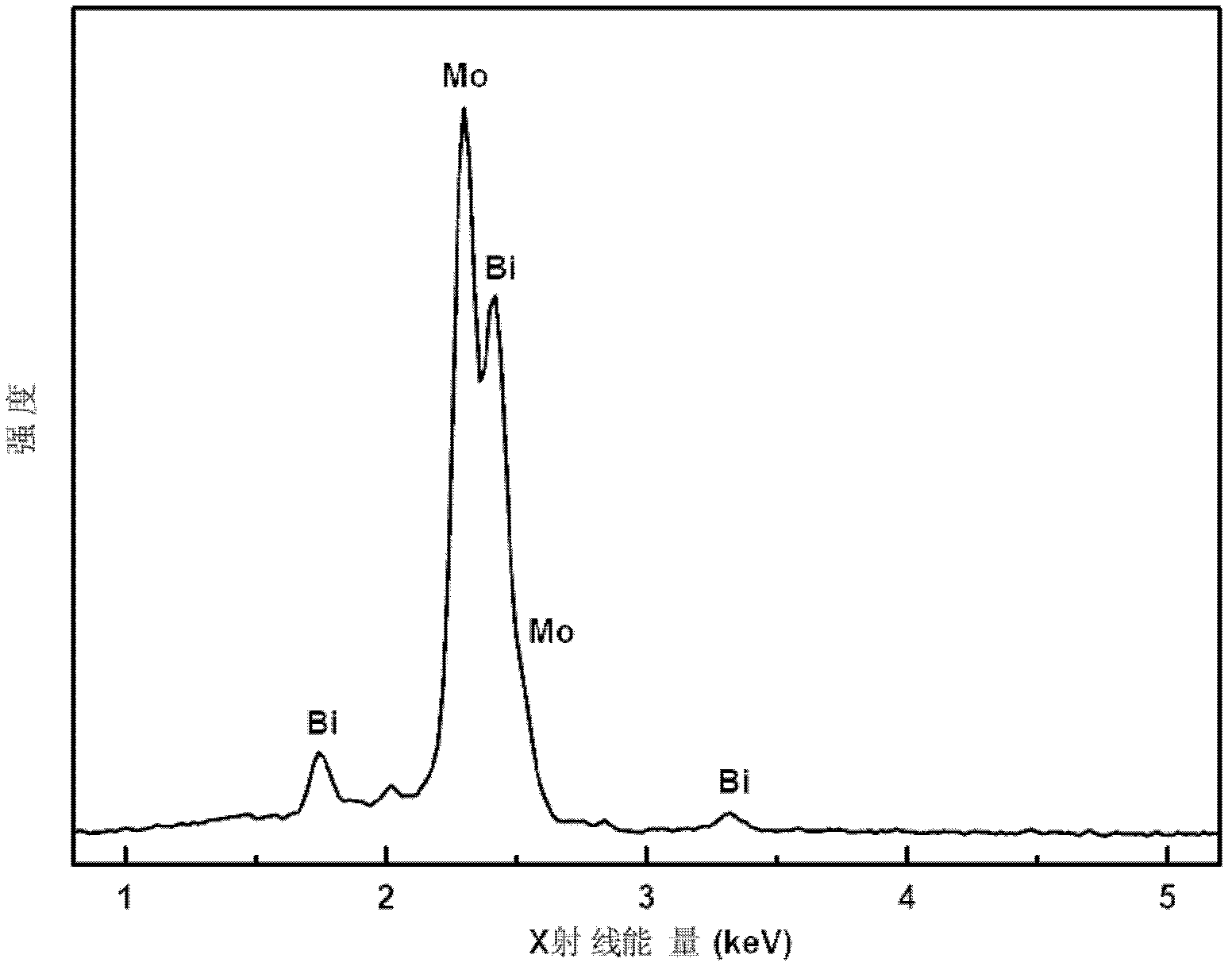

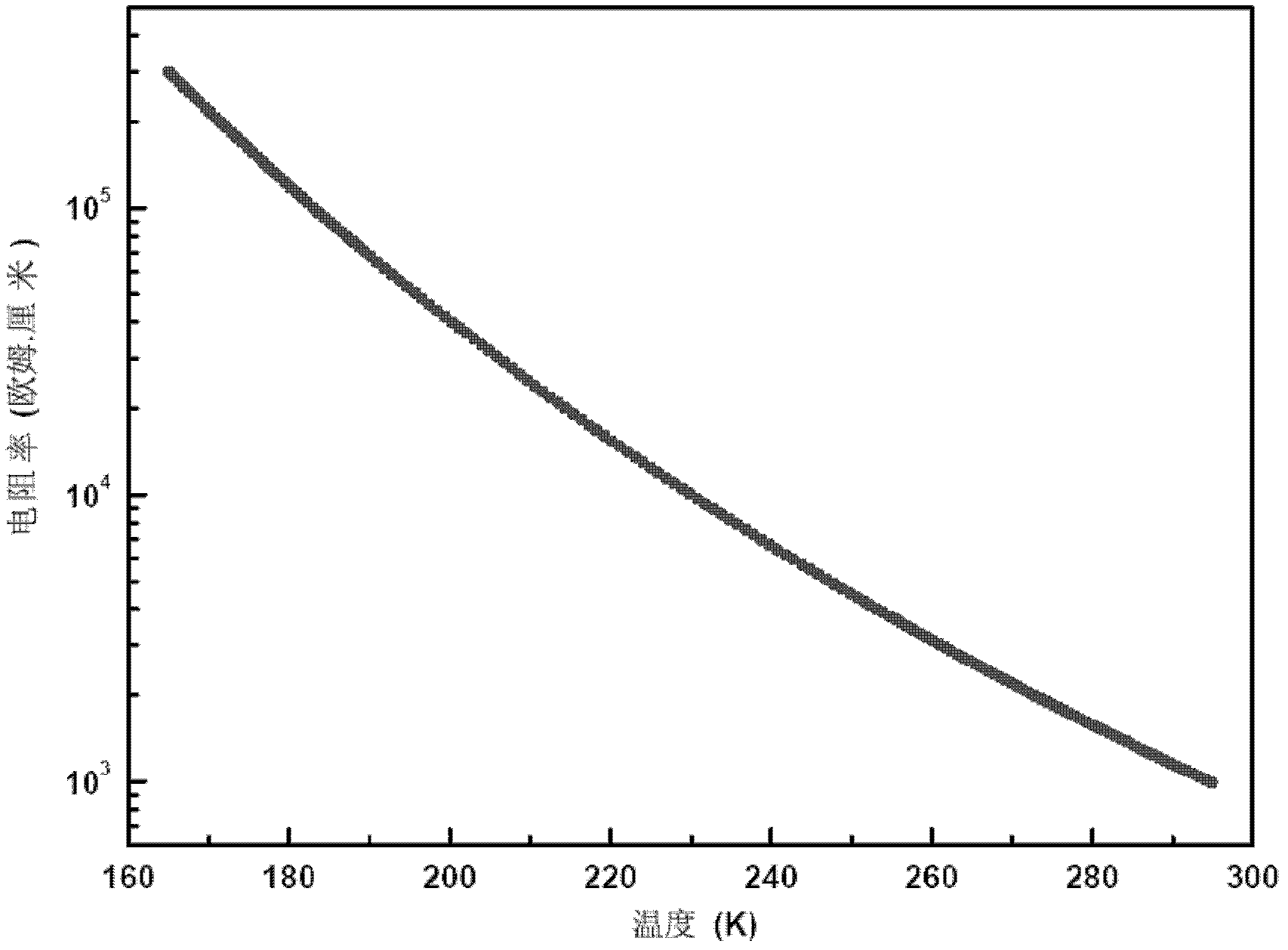

Method for preparing single-phase polycrystalline bismuth molybdate by using solid-phase reaction method and application

InactiveCN102345163ANo pollution in the processPollution fitPolycrystalline material growthSingle crystal growth detailsSolid state reaction methodStructural formula

The invention discloses a method for preparing single-phase polycrystalline bismuth molybdate by using a solid-phase reaction method and application. The method comprises the following steps of: mixing bismuth powder and molybdenum trioxide according to a molar ratio of 1:5; ball-milling obtained mixture under inert gas atmosphere; and cleaning, tabletting, calcining and sintering to obtain the single-phase polycrystalline bismuth molybdate after ball-milling. The single-phase polycrystalline bismuth molybdate has a structural formula of Bi0.27Mo2O5 and shows semiconductor behavior at 160-300K. In the invention, the single-phase polycrystalline bismuth molybdate polycrystal is prepared by a method for combining mechanical ball-milling and solid-phase sintering; and the method has the advantages of simple preparation process, low cost, no environmental pollution, yield of over 90 percent and suitability for large-scale production.

Owner:JINAN UNIVERSITY

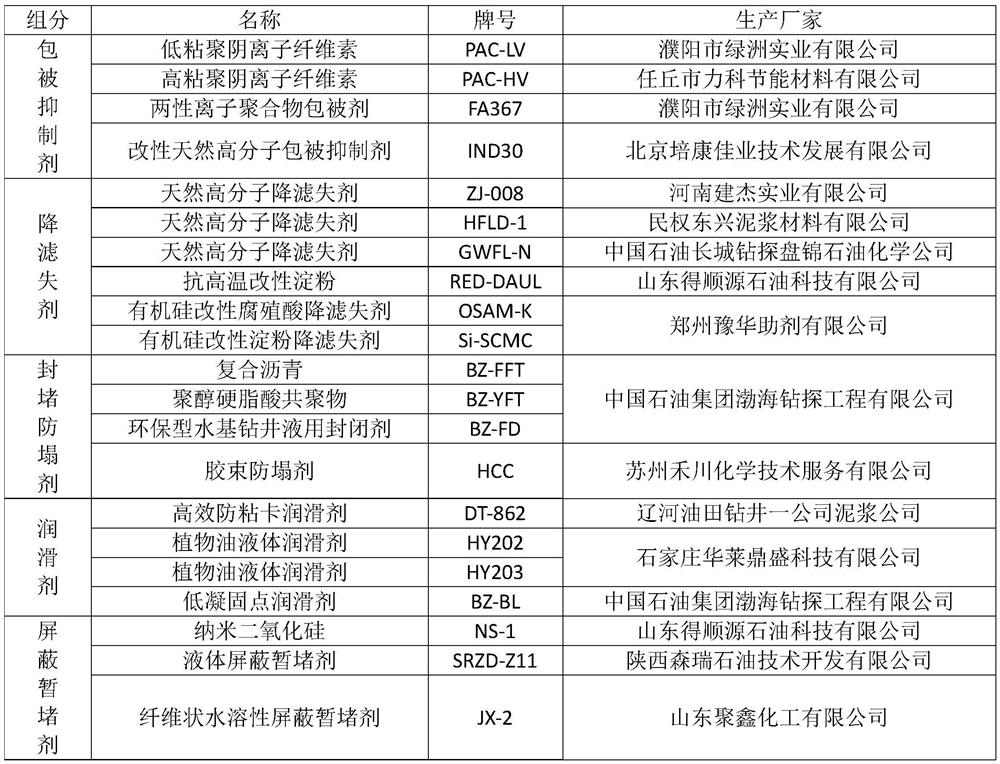

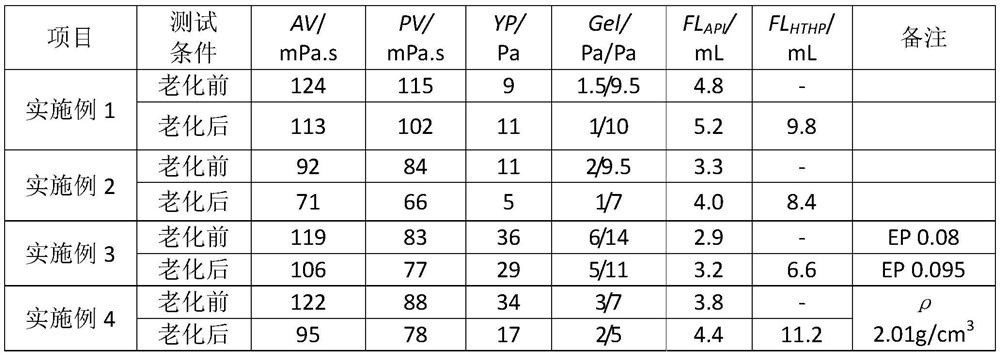

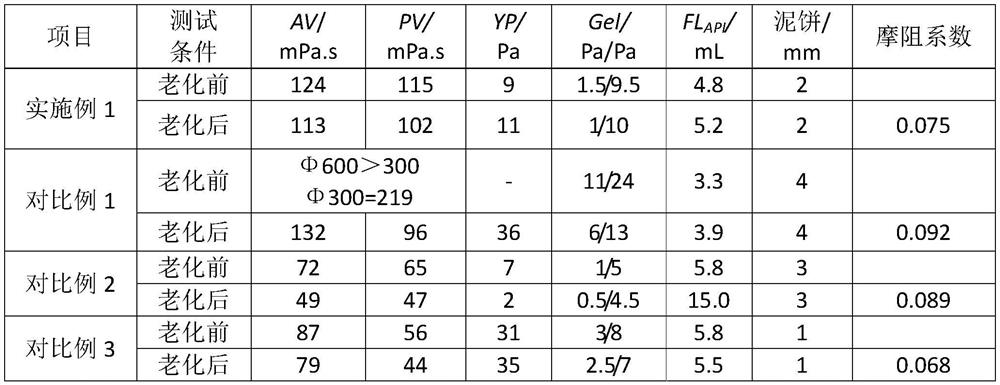

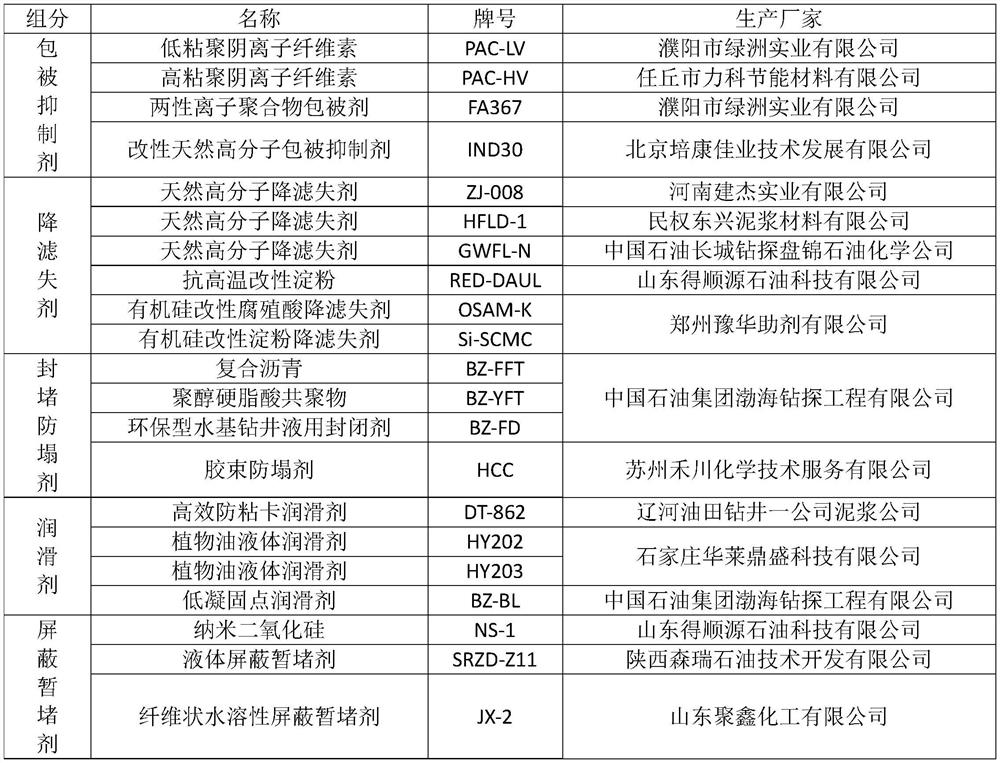

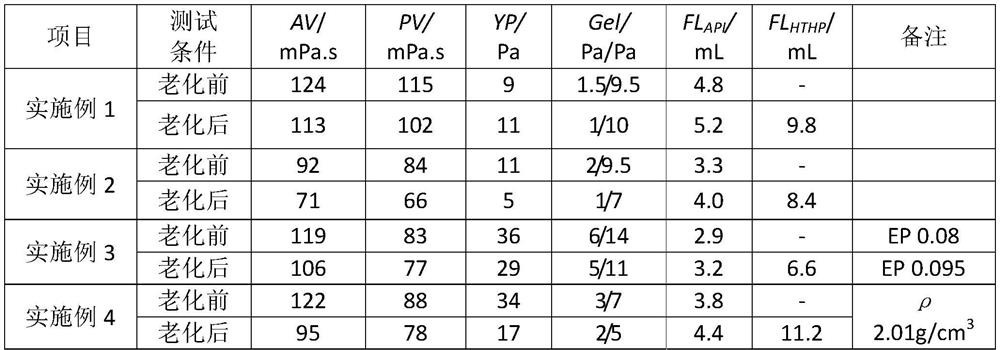

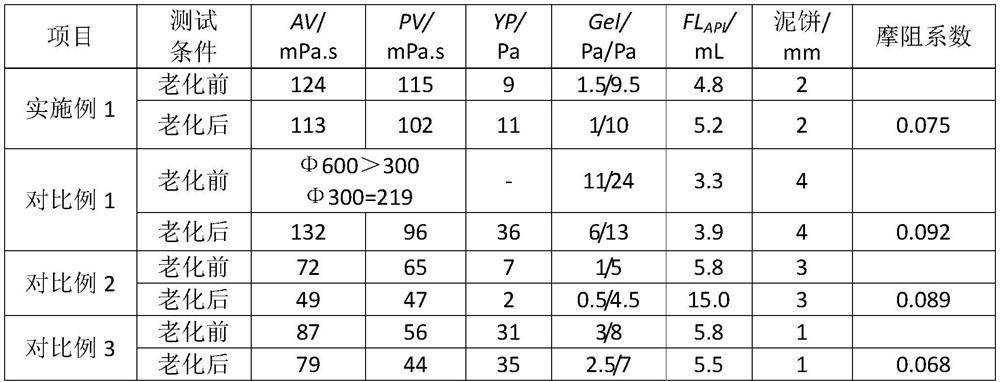

Desulfonation environment-friendly water-based drilling fluid and preparation method thereof

The invention discloses a desulfonation environment-friendly water-based drilling fluid and a preparation method thereof. The drilling fluid comprises the following components in parts by weight: 100parts of solvent water, 2-5 parts of bentonite, 0.1-0.25 part of anhydrous sodium carbonate, 0.4-0.5 part of coating inhibitor, 3-5 parts of filtrate reducer, 2-3 parts of plugging anti-collapse agent, 1-3 parts of lubricant, 1-3 parts of shielding temporary plugging agent, 0-400 parts of barite and 0-10 parts of sodium chloride. The method sequentially comprises the following steps: preparing pre-hydrated bentonite slurry; preparing a coating inhibitor glue solution; uniformly mixing and stirring water, the pre-hydrated bentonite slurry, the coating inhibitor glue solution, the filtrate reducer, the plugging anti-collapse agent, the lubricant and the shielding temporary plugging agent, and selectively adding sodium chloride and barite to obtain the plugging agent. The drilling fluid is free of a sulfonation treatment agent, wherein the raw materials are wide in source and easy to obtain, so that the drilling fluid is suitable for light water wells, brine wells, highly-deviated wells / extended reach wells and high-temperature and high-density wells; the field application effect is good, the environmental protection requirement is met, the preparation method is simple, conditions areeasy to control, and both of economic benefits and social benefits are improved.

Owner:CNPC BOHAI DRILLING ENG +1

Mountain spring running water fish farming method

PendingCN111248111AReduce sizeReduce morbidityClimate change adaptationPisciculture and aquariaEcological environmentCommon carp

The invention discloses a mountain spring running water fish farming method, which belongs to the field of breed aquatics. The mountain spring running water fish farming method comprises the followingsteps of: fish pond site selection, and the fish pond is selected and built in a place where the surrounding natural ecological environment is excellent, the terrain is flat, the river water is freshand pollution-free, the water injection and drainage are convenient, and the annual water flow is basically stable; fish pond construction: the construction shape and size of the fish pond depends onthe terrain and water flow; fish breeding: herbivorous grass carps liking a clear water environment are mainly bred, and a small amount of carp can be matched; feeding management: the feed mainly includes wild grass, aquatic grass, tender vegetable leaves and artificially grown green feed, and a floating forage frame for feeding green feed can be arranged in the pond; and fish disease preventionand control, which adheres to the principle of ''focusing on prevention, and prevention is more important than cure''. The breeding method is scientific and reasonable, and the breeding quality and efficiency are higher, which improves the economic benefits of the enterprise.

Owner:安徽年喜水产养殖有限公司

3D (three-dimensional) micronano ball-flower magnesium molybdate and preparation method thereof

ActiveCN106892457AUniform shapeHigh purityMolybdeum compoundsNanotechnologySodium molybdateMolybdate

The invention discloses a 3D (three-dimensional) micronano ball-flower magnesium molybdate and a preparation method thereof. The preparation method includes: firstly, configuring a P123 water solution A, mixing magnesium chloride hexahydrate with ethylene glycol into a solution B and mixing sodium molybdate dehydrate with the water solution A into a solution C; secondly, mixing the solution B with the solution C prior to moving the mixture to a reaction kettle for sealing and hydrothermal reaction; after reaction is completed, subjecting the product to vacuum filter washing and drying to obtain magnesium molybdate nanoparticles; finally, placing the magnesium molybdate nanoparticles in air atomosphere for constant-temperature calcination, rapidly taking out the magnesium molybdate nanoparticles and putting the same in deiondized water to obtain the 3D micronano ball-flower magnesium molybdate. The 3D micronano ball-flower magnesium molybdate and the preparation method thereof have the advantages that the magnesium molybdate nanoparticles can be self-assembled to 3D micronano flower balls high in specific surface, high in purity and uniform in morphology, and the preparation method is simple, low in cost, high in repeatability and free of pollution to environment.

Owner:SHAANXI UNIV OF SCI & TECH

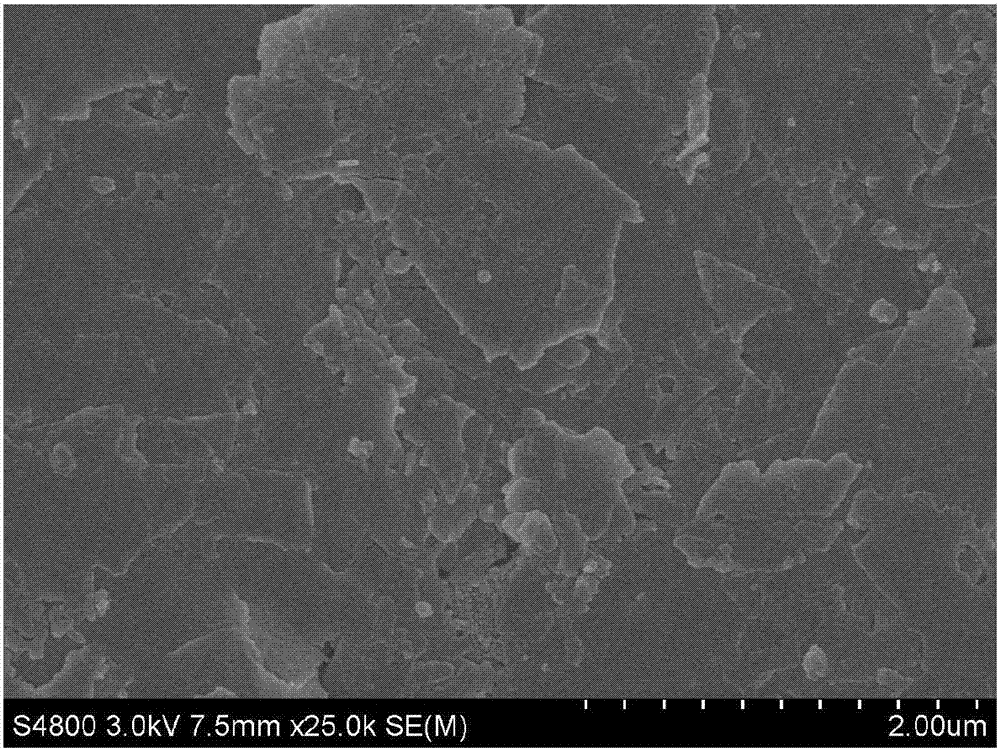

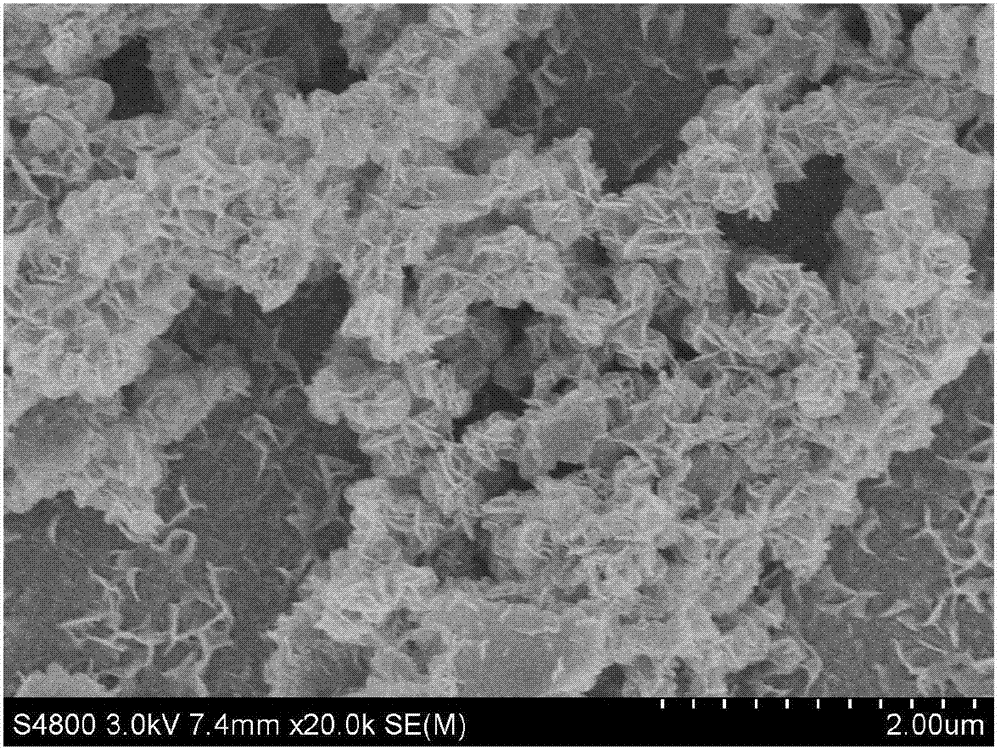

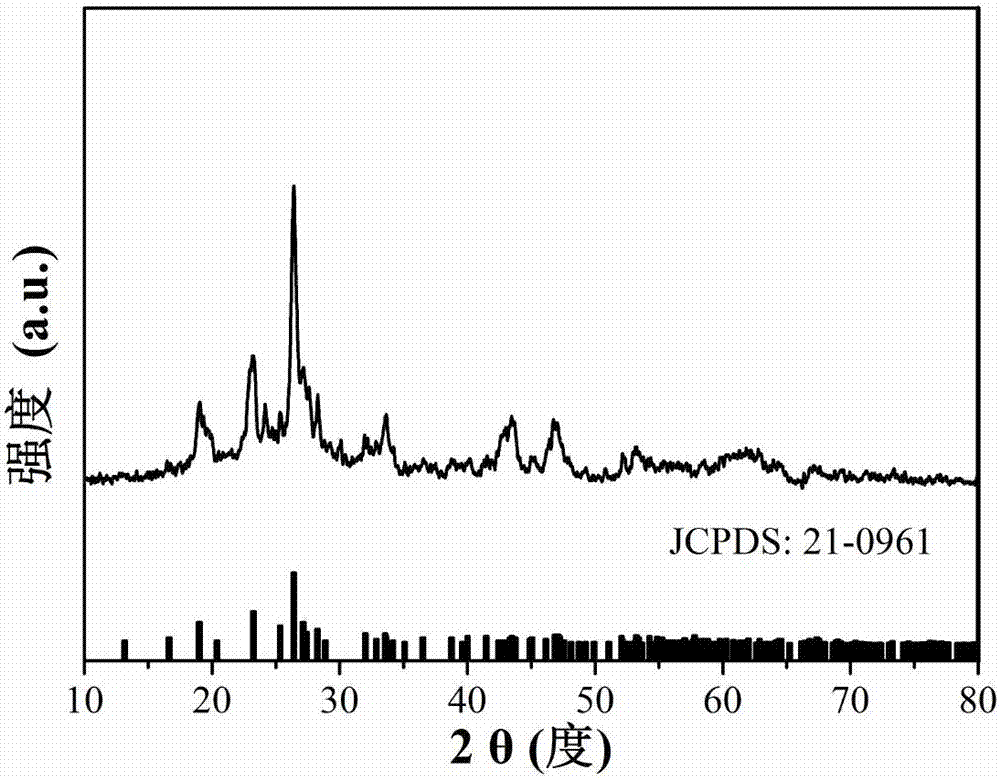

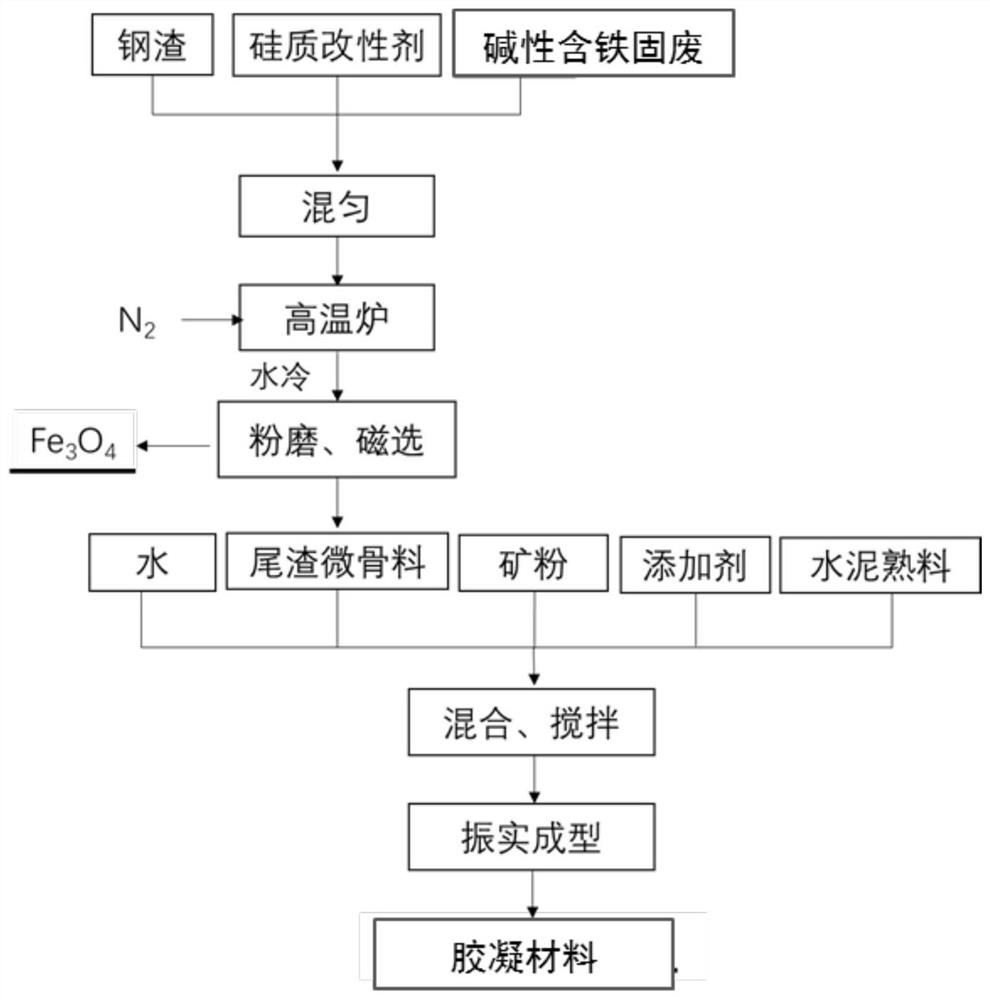

Method for preparing tailing micro-aggregate and simultaneously producing magnetite

ActiveCN114620964AImprove performanceReduce pollutionSolid waste managementIron oxides/hydroxidesSlagRed mud

The method comprises the following steps: mixing steel slag, an alkaline iron-containing solid waste and a siliceous modifier to obtain a mixture, adding the mixture into a high-temperature furnace, calcining in an inert atmosphere, cooling, then carrying out a thermal insulation reaction, and carrying out water cooling, drying, grinding and magnetic separation to obtain the magnetite and the tailing micro-aggregate. The alkaline iron-containing solid waste is selected from red mud or blast furnace ash. The preparation method provided by the invention can simultaneously treat the steel slag and various industrial solid wastes, realizes maximum resource utilization of the industrial solid wastes, reduces environmental pollution, and is simple in preparation process and suitable for large-scale production. The prepared tailing micro-aggregate is excellent in performance and can be used for replacing various building materials.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing single-phase polycrystalline bismuth molybdate by using solid-phase reaction method and application

InactiveCN102345163BNo pollution in the processPollution fitPolycrystalline material growthSingle crystal growth detailsMolybdateSolid state reaction method

The invention discloses a method for preparing single-phase polycrystalline bismuth molybdate by using a solid-phase reaction method and application. The method comprises the following steps of: mixing bismuth powder and molybdenum trioxide according to a molar ratio of 1:5; ball-milling obtained mixture under inert gas atmosphere; and cleaning, tabletting, calcining and sintering to obtain the single-phase polycrystalline bismuth molybdate after ball-milling. The single-phase polycrystalline bismuth molybdate has a structural formula of Bi0.27Mo2O5 and shows semiconductor behavior at 160-300K. In the invention, the single-phase polycrystalline bismuth molybdate polycrystal is prepared by a method for combining mechanical ball-milling and solid-phase sintering; and the method has the advantages of simple preparation process, low cost, no environmental pollution, yield of over 90 percent and suitability for large-scale production.

Owner:JINAN UNIVERSITY

A method for improving the corrosion resistance of sintered NdFeB magnets

ActiveCN103668178BLittle influence on magnetic propertiesChange structureInductances/transformers/magnets manufactureMetallic material coating processesMetallurgyIrradiation

The invention discloses a method for improving the corrosion resistance of a sintered neodymium iron boron magnet, and relates to a permanent magnet material surface modification technology. The method mainly comprises the following steps: 1, carrying out sanding, polishing, cleaning and drying pretreatment of a sintered neodymium iron boron magnet surface for processing; 2, clamping the above obtained pretreated sintered neodymium iron boron magnet on a workbench; 3, carrying out laser irradiation of the sintered neodymium iron boron magnet surface for processing under the protection of vacuum or a gas until a grain boundary phase melts to form a micro melting pool; 4, sending metal or compound nano-powder into the grain boundary micro melting pool through a powder sending device for the micro-alloying of the nano-powder and the grain boundary phase; and 5, cleaning up unalloyed nano-powder to obtain a sintered neodymium iron boron magnet with a selectively alloying modified surface grain boundary. The method can effectively change the component and structure of the magnet surface grain boundary phase, can improve the physical and chemical properties of the grain boundary phase, can inhibit the intercrystalline corrosion of the surface of the magnet, and can substantially improve the corrosion resistance of the magnet. The method has the advantages of simple process, easy operation, and suitableness for the large-scale batch production.

Owner:东台城东科技创业园管理有限公司

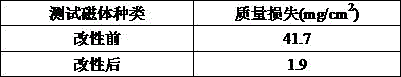

Anti-cancer drug composition

ActiveCN108309985AImprove solubilityImprove anti-cancer effectOrganic active ingredientsAntineoplastic agentsSolubilityMedicine

The invention discloses an anti-cancer drug composition. The anti-cancer drug composition is characterized by being composed of 7-ethyl-10-hydroxycamptothecine and sodium glycyrrhetinate, and is prepared by the following method comprising the steps: (1) preparing raw materials: weighing 7-ethyl-10-hydroxycamptothecine and sodium glycyrrhetinate; and (2) ball-milling through a roller: performing ball-milling through the roller on 7-ethyl-10-hydroxycamptothecine and sodium glycyrrhetinate, wherein ball-milling rotation speed is 10-30 rpm, the temperature is 20-30 DEG C, and ball-milling time is12-36 hours. The anti-cancer drug composition disclosed by the invention is simple in preparation process, is free of pollution on environment, is suitable for large-scale production, remarkably improves solubility of 7-ethyl-10-hydroxycamptothecine, and has a very good anticancer effect.

Owner:ZHEJIANG UNIV OF TECH

High-utilization-rate organic fertilizer for rice, and preparation method of high-utilization-rate organic fertilizer

InactiveCN108101644ALow costIncrease profitBio-organic fraction processingMagnesium fertilisersSodium BentoniteHydrogen phosphate

The invention discloses a high-utilization-rate organic fertilizer for rice. The high-utilization-rate organic fertilizer is prepared from the following raw materials in parts by weight: 20-30 parts of rice straw powder, 8-18 parts of corn meal, 8-15 parts of dried geese dung, 9-16 parts of diammonium hydrogen phosphate, 6-9 parts of modified bentonite, 5-7 parts of honeysuckle flower, 2-6 parts of bacillus pasteurii and 5-9 parts of flammulina velutipes residue. The invention also discloses a preparation method of the high-utilization-rate organic fertilizer for the rice. The high-utilization-rate organic fertilizer for the rice is safe and environmentally-friendly; the method is simple and suitable for industrial production; furthermore, the organic fertilizer prepared by the method is high in utilization rate and remarkably improves the enterprise benefit.

Owner:滁州广洋湖米业有限公司

Preparation method of biological film mono non-staple-food composite modified hydrophobic starch

The invention discloses a preparation method of biological film mono non-staple-food composite modified hydrophobic starch. The preparation method comprises the following steps: cyclically drying starch with hot air; adding dry starch, triglyceride and succinate into a grinding machine together; grinding until the materials are uniformly mixed; dissolving the uniformly mixed starch into an ethanol solution; adjusting the pH (Potential of Hydrogen) value and adding hexamethyldisilazane; heating and stirring to obtain a starch solution; carrying out starch molecule diffusion and transportation on the starch solution under the permeation effect of a biological film; and after finishing transportation, carrying out precipitation, filtering and vacuum drying treatment to obtain the composite modified hydrophobic starch. According to the preparation method of the biological film mono non-staple-food composite modified hydrophobic starch, disclosed by the invention, the used raw materials are simple and easy to obtain and the preparation method is simple; preparation conditions are moderate and the preparation method is safe and environmentally friendly and is suitable for industrialized production; the prepared composite modified hydrophobic starch has stable performances, a high hydrophobic capability, good dispersity and solubility and high reaction efficiency, and can be widely applied.

Owner:ANHUI RUIYAN NEW MATERIAL TECH RES INST

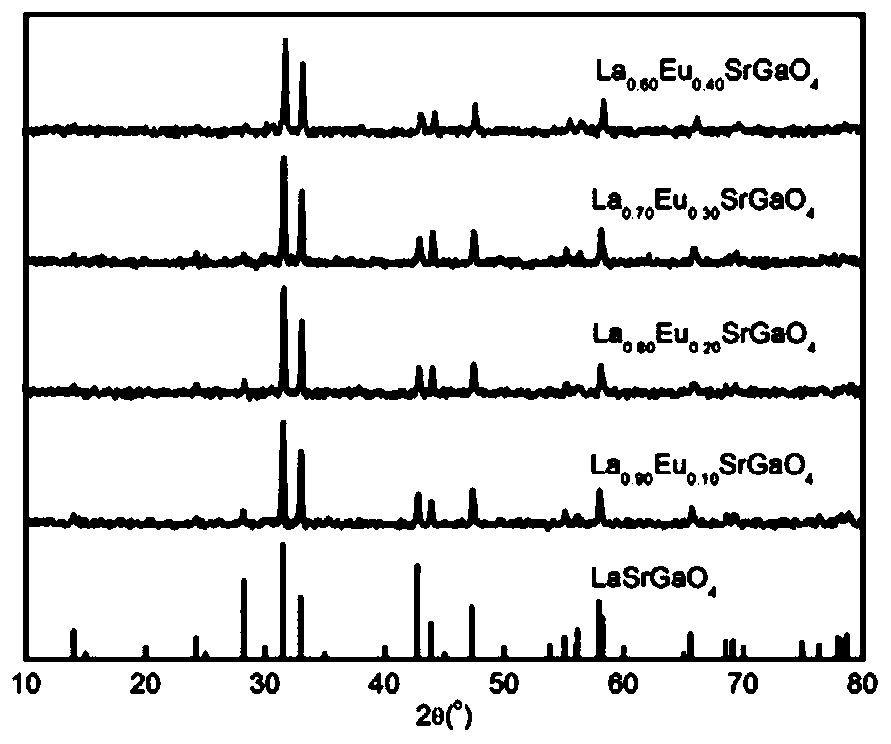

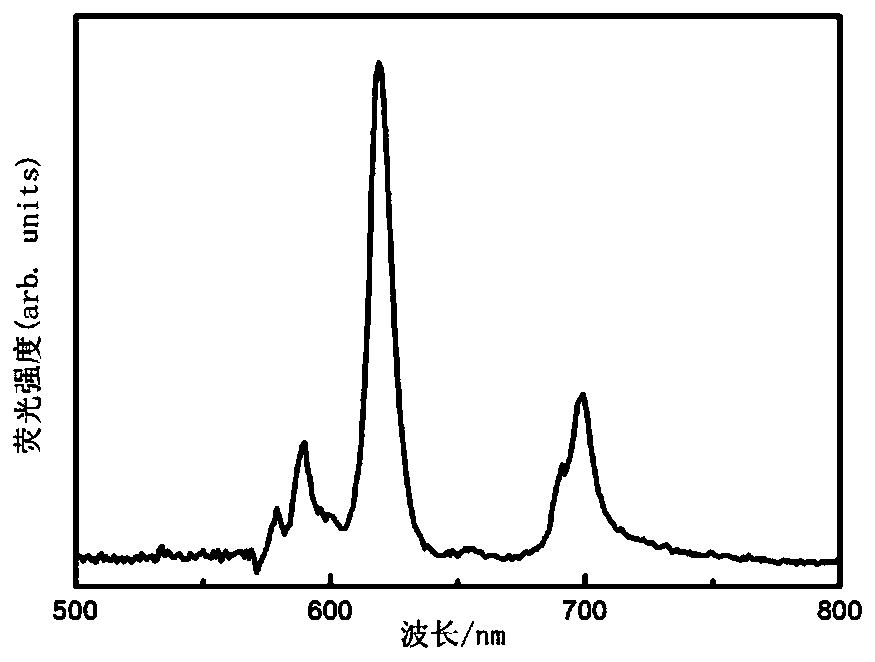

Gallate red fluorescent powder for white light LED as well as preparation method thereof

ActiveCN110591711AHigh luminous intensityGood chemical stabilityEnergy efficient lightingLuminescent compositionsChemistryRed light

The invention discloses gallate red fluorescent powder for a white light LED. The chemical general formula of the gallate red fluorescent powder is La1-xMxSrGaO4, wherein M is Eu or Pr, and x is morethan 0 and less than or equal to 1. The gallate red fluorescent powder provided by the invention is prepared by taking LaSrGaO4 as a substrate and doping rare earth ions Eu<3+> or Pr<3+> through high-temperature solid-phase reaction. The gallate red fluorescent powder can emit bright red light under ultraviolet excitation and has high light-emitting intensity; furthermore, physical and chemical stability is high, raw materials are easily available, and the preparation process is simple, pollution-free to the environment and suitable for large-scale production. The red fluorescent powder can bematched with blue and green fluorescent powder to realize ultraviolet excitation on the white light LED, and has application value in the field of the white light LED.

Owner:LINGNAN NORMAL UNIV

Preparation method of glaze and glaze plate

The invention relates to a glaze material which comprises the following components in parts by weight: 30-50 parts of inorganic gel, 1-3 parts of modifier, 10-20 parts of fine aggregate, 30-50 parts of coarse aggregate, 3-5 parts of reinforced fiber, 0.2-0.4 part of water reducer, 0.01-0.06 part of retarder, 0.01-6 parts of moisture repellent, 0.1-0.5 parts of water-retaining agent, 0.5-2 parts of flexibilizer, 0.5-3 parts of densification agent and 2-6 parts of mineral pigment. The invention also provides a preparation method of a glaze material plate. Most of the components of the glaze material are common inorganic materials, thus being low in cost, having no toxicity and radiation, having no contamination, and being environment-friendly. When in preparation of the glaze material plate by using the glaze material, the step of high temperature roasting is eliminated, the molded glaze material plate can be cured at normal temperature, and carbon emission can be greatly reduced, so that the preparation method is environment-friendly and energy-saving.

Owner:深圳市爱思宝科技发展有限公司

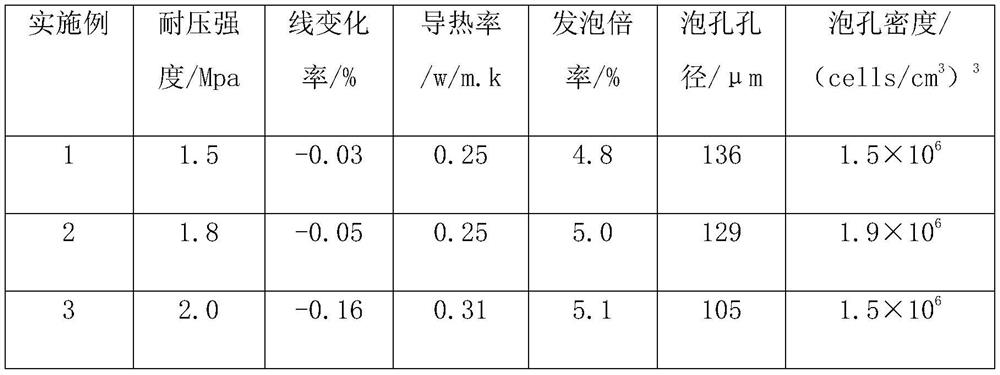

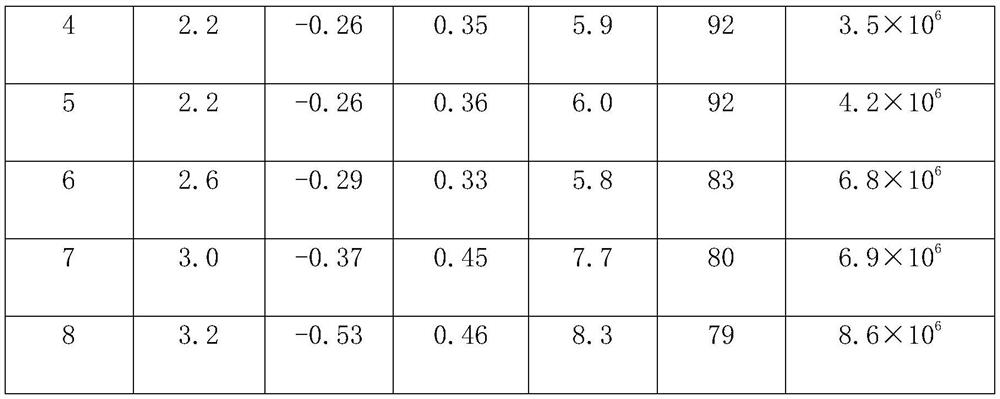

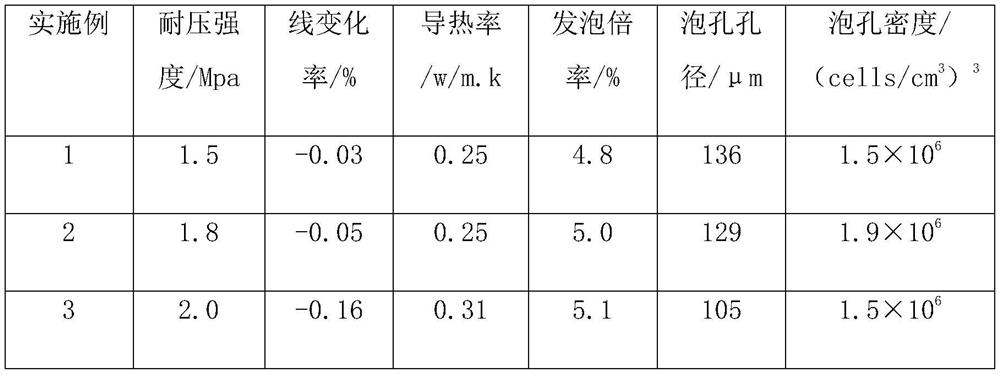

Method for preparing light PET composite foam material by utilizing melt-blowing technology

The invention discloses a method for preparing a light PET composite foaming material by utilizing a melt-blowing technology. The method comprises the steps: proportioning; respectively weighing PET resin, SG-2 polyvinyl chloride resin, wood flour, ethylene propylene diene monomer, hydroxymethyl cellulose, polylactic acid, a nucleating agent, a dispersing agent, a flame retardant and a foaming agent; modifying the raw materials; putting PET resin, SG-2 polyvinyl chloride resin, wood flour, ethylene propylene diene monomer, hydroxymethyl cellulose and polylactic acid into a reaction kettle fora heating reaction, then adding the nucleating agent, the dispersing agent, the flame retardant and the foaming agent for a continuous reaction, and thus obtaining modified raw material slices; carrying out melting treatment; slicing, melting and blending the modified raw materials, and putting into a reaction kettle for heating reaction to obtain a melt-blown material; carrying out melt-blow molding; and placing the melt-blown material in a melt-blown screw extruder, and carrying out melt-blown molding to obtain the light PET composite material which is excellent in performance and suitable for large-scale popularization.

Owner:宜兴市泰宇汽车零部件有限公司

High-quality glass products and their production processes

The invention discloses a high-quality glass product and a production process thereof. The glass product comprises raw materials in the following weight ratio: 40-65 parts of silicon dioxide powder, 3-5 parts of aluminum oxide, 20-25 parts of titanium dioxide powder, oxygen 0.5-1.5 parts of sodium silicate, 0.1-0.5 parts of cobalt powder, 0.5-0.9 parts of selenium powder, and 5-10 parts of magnesium oxide. The production process of the glass product is as follows: (1) feeding the required raw materials into a blender for uniform mixing; (2) heating the mixture to make it reach a molten state; (3) sending the glass melt into a molding Machine to make glass products of different shapes and specifications, and then anneal the products. The invention has the advantages of simple production process, low production cost, no pollution in the production process, smooth surface of the produced glass product, high compressive strength and light weight.

Owner:西安亚岱新能源科技有限公司

A method for preparing light-weight pet composite foam material by melt blown technology

The invention discloses a method for preparing light-weight PET composite foaming materials by using melt-blown technology, including ingredients; PET resin, SG-2 polyvinyl chloride resin, wood powder, EPDM rubber, and methylol Cellulose, polylactic acid, nucleating agent, dispersant, flame retardant and foaming agent; raw material modification; PET resin, SG‑2 polyvinyl chloride resin, wood powder, EPDM rubber, hydroxymethyl fiber Put element and polylactic acid into the reaction kettle to heat and react, then add nucleating agent, dispersant, flame retardant and foaming agent to continue the reaction to obtain modified raw material slices; melt processing; melt and blend the modified raw material slices, and put them into Heat up the reaction in the reactor to obtain the melt-blown material; melt-blown molding; put the melt-blown material in the melt-blown screw extruder, and after the melt-blown molding, the lightweight PET composite performance is excellent, which is suitable for mass promotion.

Owner:宜兴市泰宇汽车零部件有限公司

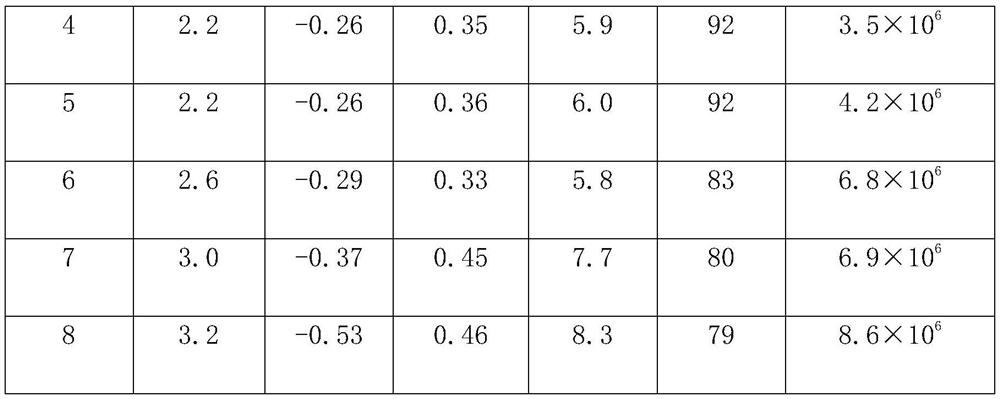

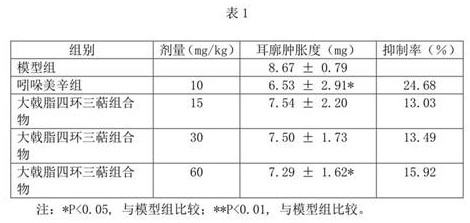

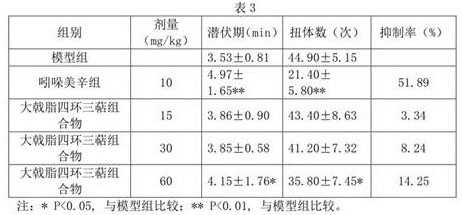

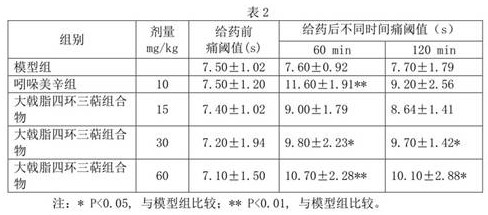

Euphorbium active tetracyclic triterpene composition and preparation method and use thereof

InactiveCN112315993AGood anti-inflammatory and analgesic effectProlonged writhing latencyOrganic active ingredientsSenses disorderAnalgesics drugsXylylene

The present invention relates to the technical field of extraction and purification of active tetracyclic triterpene compositions from euphorbium, in particular to an euphorbium active tetracyclic triterpene composition and a preparation method and use thereof. The euphorbium active tetracyclic triterpene composition comprises 70%-90% by weight of euphorbium active tetracyclic triterpene, the euphorbium active tetracyclic triterpene comprises euphadienol and euphol. The preparation method comprises the following steps: carrying out reflux extraction on eeuphorbium in an ethanol solution and vacuum concentration to obtain an extract, dissolving the extract in the ethanol solution, stirring the dissolved extract with silica gel, carrying out adsorbing with a silica gel column, and collectingan eluate to obtain the euphorbium active tetracyclic triterpene composition. The preparation method has characteristics of low cost, no pollution and suitability for industrialization, and the obtained euphorbium active tetracyclic triterpene composition has good anti-inflammatory and analgesic effects, can relieve auricle swelling of mice caused by xylene, improves a pain stasis value of a mouse pain model caused by a hot plate method, can prolong a mouse twisting incubation period caused by acetic acid, significantly reduce the number of twisting of mice and can be used to prepare anti-inflammatory and analgesic drugs.

Owner:XINJIANG INST OF MATERIA MEDICA

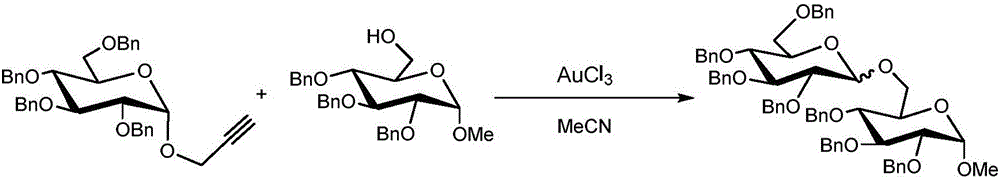

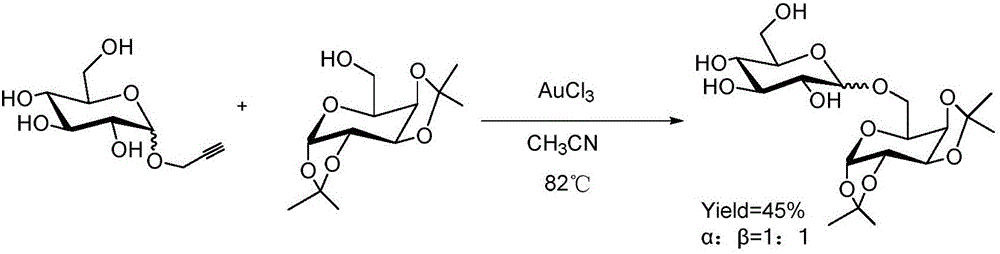

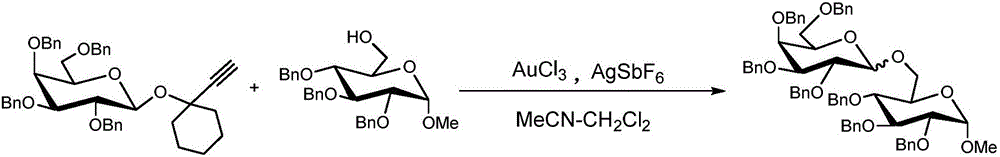

Oligosaccharide synthesizing method

ActiveCN106674302ASimple structureEasy to storeSugar derivativesSugar derivatives preparationState of artOrganic solvent

The invention discloses an oligosaccharide synthesizing method which is characterized in that full-benzyl protection propargyl alcohol glycoside is utilized as a glycosyl donor, 6-site glycosyl intermediate or glycosyl with a -Tr protecting group is utilized as a glycosyl acceptor, and the glycosyl donor and the glycosyl acceptor are dissolved in an organic solvent according to a mole ratio of (1 to 6mmol) to 1mmol to (0.1 to 1mmol) to perform glycosylation reaction under the catalysis of ferric salt. Compared with the prior art, the oligosaccharide synthesizing method achieves the purpose that the glycosyl donor directly perform glycosylation reaction with the 6-site glycosyl intermediate with the -Tr protecting group, oligosaccharide is synthesized through a one-pot method in high yield, a reaction route is shortened, operation steps are simplified, production cost is reduced, and heavy metal ion pollution is effectively avoided. In addition, the oligosaccharide synthesizing method has the advantages of being green, environment-friendly and suitable for industrial production and having larger technological innovation and good application prospect.

Owner:EAST CHINA NORMAL UNIV

Ecologic bactericide for fish culture

InactiveCN105616855ANo pollution in the processPollution fitAntibacterial agentsClimate change adaptationBiotechnologyDisease

The invention relates to the field of fish culture, and especially relates to an ecologic bactericide for fish culture. The ecologic bactericide mainly comprises, by weight, 10-30 parts of Chinese yam powder, 5-15 parts of Folium Ginkgo powder, 10-20 parts of licorice root, 10-20 parts of honeysuckle flower, 5-10 parts of chrysanthemum flower and 5-10 parts of composite vitamins. The ecologic bactericide has the advantages of naturalness, no pollution, no toxic effects, suitableness for promotion and use, low cost, convenient operation, wide-spectrum and high-efficiency prevention of pathogen infection, and substantial enhancement of the disease resistance of fishes, and is a novel green ecologic bactericide.

Owner:CHONGQING TONGJI AGRI DEV CO LTD

A kind of desulfonated environment-friendly water-based drilling fluid and preparation method thereof

The invention discloses a desulfonated environment-friendly water-based drilling fluid and a preparation method thereof. The drilling fluid comprises 100 parts by weight of solvent water, 2-5 parts of bentonite, 0.1-0.25 parts of anhydrous sodium carbonate, 0.4- 0.5 parts of coating inhibitor, 3 to 5 parts of fluid loss reducer, 2 to 3 parts of plugging and anti-slump agent, 1 to 3 parts of lubricant, 1 to 3 parts of shielding temporary plugging agent, 0 to 400 parts of barite and 0 ~10 parts of sodium chloride; specifically, by preparing pre-hydrated bentonite slurry; preparing coated inhibitor glue; mixing water, pre-hydrated bentonite slurry, coated inhibitor glue, fluid loss reducer, plugging and anti-collapse The drilling fluid is prepared by mixing and stirring well with the agent, lubricant and shielding temporary plugging agent, and selectively adding sodium chloride and barite; the drilling fluid abandons the sulfonation treatment agent, and the raw materials are widely sourced and easy to obtain, which is not only suitable for freshwater wells , and is suitable for brine wells, high-inclination wells / extended-reach wells, high-temperature and high-density wells, has good field application effects, meets environmental protection requirements, and has a simple preparation method and easy control of conditions, realizing the unity of economic and social benefits.

Owner:CNPC BOHAI DRILLING ENG +1

Tablet candy for treating skin stubborn diseases and preparation method thereof

PendingCN111227089AReduce pollutionSimple processConfectionerySweetmeatsBiomedical engineeringOfficinalis

The invention discloses a tablet candy for treating skin stubborn diseases, belongs to the technical field of treatment of skin stubborn diseases, and can solve a problem that an existing tablet candycannot treat skin stubborn diseases. The tablet candy comprises the following components in parts by mass: 20-45 parts of zaocys dhumnade, 20-35 parts of emblic leafflower fruit, 15-30 parts of radixpolygonati officinalis, 20-30 parts of endothelium corneum gigeriae galli, 2-20 parts of starch and 1-5 parts of talcum powder. The invention also discloses a preparation method of the tablet candy.Through the preparation method, program control can be realized, automatic production can be carried out, and production environment is fully enclosed for coating, can reduce pollution to the environment and meet GMP requirements. Moreover, the preparation method is simple and easy to master, can shorten operation time, reduce labor intensity of workers, and improve quality of the tablet candy. The prepared tablet candy can effectively treat patients with skin stubborn diseases, improve medicinal value of the candy, and has strong practicability.

Owner:艾麦尔·麦米提力

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com