A kind of desulfonated environment-friendly water-based drilling fluid and preparation method thereof

A water-based drilling fluid, environmentally friendly technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as unknown economy and lack of universality, achieve a wide range of applications and meet field application requirements , the effect of easy availability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

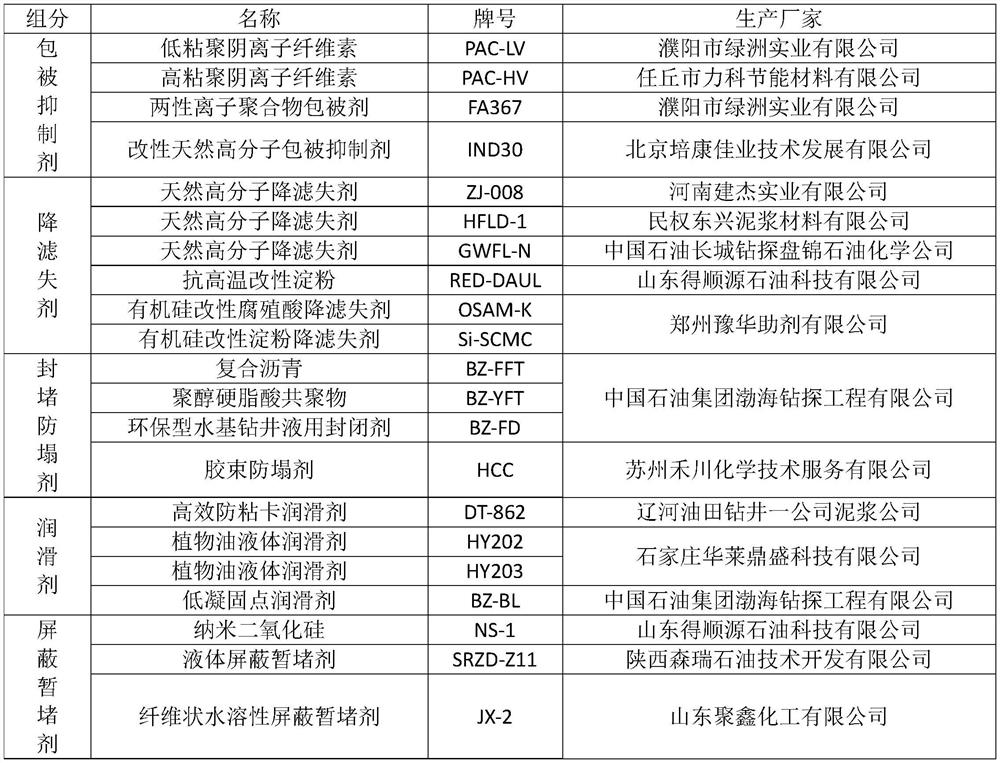

Method used

Image

Examples

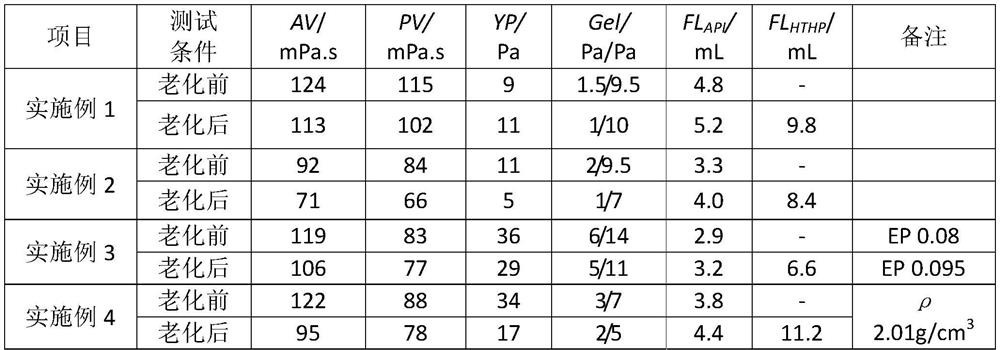

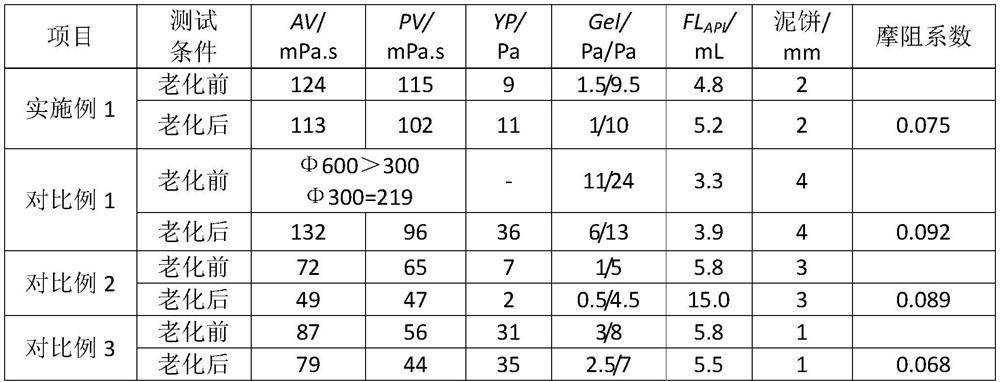

Embodiment 1

[0033] A freshwater well desulfonated environment-friendly water-based drilling fluid product I, its preparation method is as follows:

[0034] S1. Measure 50 parts by weight of solvent water, add 5 parts by weight of calcium-based bentonite sodium-modified bentonite and 0.25 parts by weight of anhydrous sodium carbonate while stirring, stir at a low speed of 3000r / min for 1h, and maintain at room temperature for 24h to prepare into pre-hydrated bentonite slurry;

[0035] S2. Measure 50 parts by weight of solvent water, slowly add 0.2 parts by weight of PAC-LV, 0.1 parts by weight of FA-367, and 0.2 parts by weight of IND30 while stirring, stir at low speed for 1 hour, and maintain at room temperature for 24 hours to make a coating inhibitor glue ;

[0036] S3. Put the pre-hydrated bentonite slurry prepared in step S1 and the coated inhibitor glue prepared in step S2 into a high stirring cup, and add 1 part by weight of GWFL-N, 2 parts by weight of Si-SCMC, 1 part by weight ...

Embodiment 2

[0038] A brine well desulfonated environment-friendly water-based drilling fluid product II, the preparation method of which is as follows:

[0039] S1. Measure 30 parts by weight of solvent water, add 3 parts by weight of natural sodium bentonite and 0.09 parts by weight of anhydrous sodium carbonate while stirring, stir at a low speed of 3000r / min for 1 hour, and maintain at room temperature for 24 hours to make a pre-hydrated bentonite slurry;

[0040] S2. Measure 40 parts by weight of solvent water, slowly add 0.1 parts by weight of PAC-LV, 0.1 parts by weight of PAC-HV, and 0.2 parts by weight of IND30 while stirring, stir at low speed for 1 hour, and maintain at room temperature for 24 hours to make a coating inhibitor glue ;

[0041] S3. Put the pre-hydrated bentonite slurry prepared in step S1, the coating inhibitor glue prepared in step S2, and the remaining 30 parts by weight of solvent water into a high stirring cup, and then add 1 part by weight of HFLD-1, 1 part...

Embodiment 3

[0043] A highly deviated well / extended reach well desulfonated environment-friendly water-based drilling fluid product III, the preparation method of which is as follows:

[0044] S1. Measure 30 parts by weight of solvent water, add 3 parts by weight of calcium-based bentonite sodium-modified bentonite and 0.15 parts by weight of anhydrous sodium carbonate while stirring, stir at a low speed of 3000r / min for 1h, and maintain at room temperature for 24h to prepare into pre-hydrated bentonite slurry;

[0045] S2. Measure 50 parts by weight of solvent water, slowly add 0.2 parts by weight of FA367 and 0.3 parts by weight of IND30 while stirring, stir at a low speed for 1 hour, and maintain at room temperature for 24 hours to prepare a coating inhibitor glue;

[0046] S3. Put the pre-hydrated bentonite slurry prepared in step S1, the coated inhibitor glue prepared in step S2, and the remaining 20 parts by weight of solvent water into a high stirring cup, and then add 2 parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com