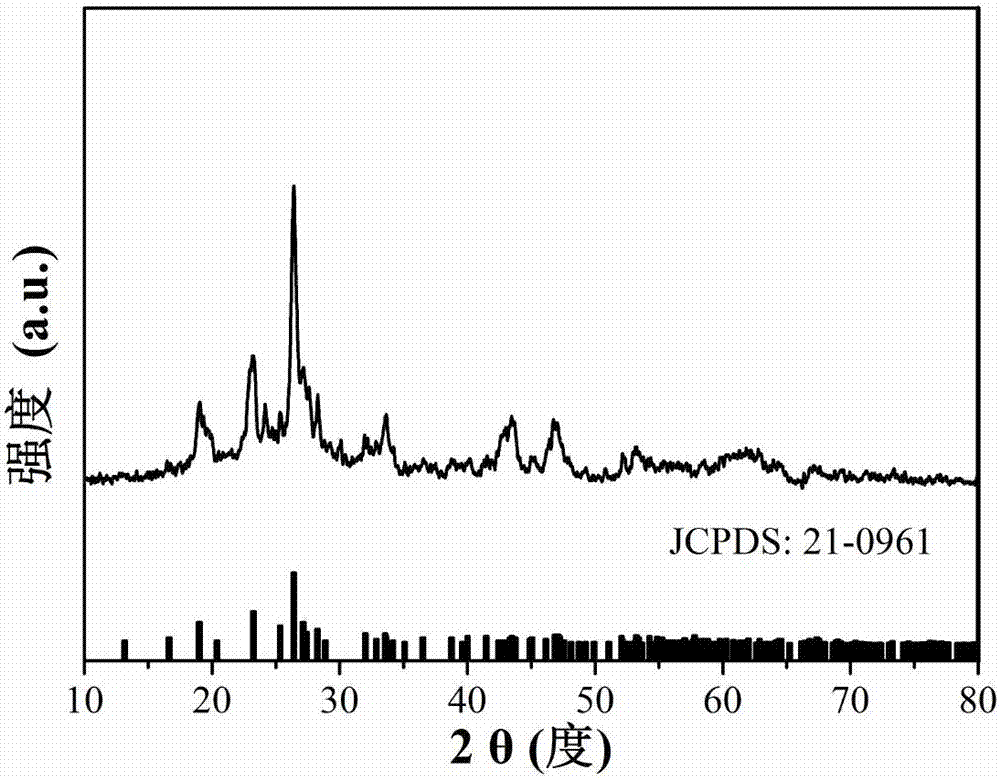

3D (three-dimensional) micronano ball-flower magnesium molybdate and preparation method thereof

A flower ball magnesium molybdate, micro-nano technology, applied in nanotechnology, chemical instruments and methods, molybdenum compounds and other directions, can solve the problem of less 3D micro-nano structure magnesium molybdate, etc., and achieve uniform morphology, low cost, and crystallinity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer) aqueous solution A that configuration concentration is 0.01 mol / liter, magnesium chloride hexahydrate and ethylene glycol are according to mass ratio 20 : 1 is mixed and formulated into solution B, and sodium molybdate dihydrate and aqueous solution A are mixed and formulated into solution C according to a mass ratio of 10:2;

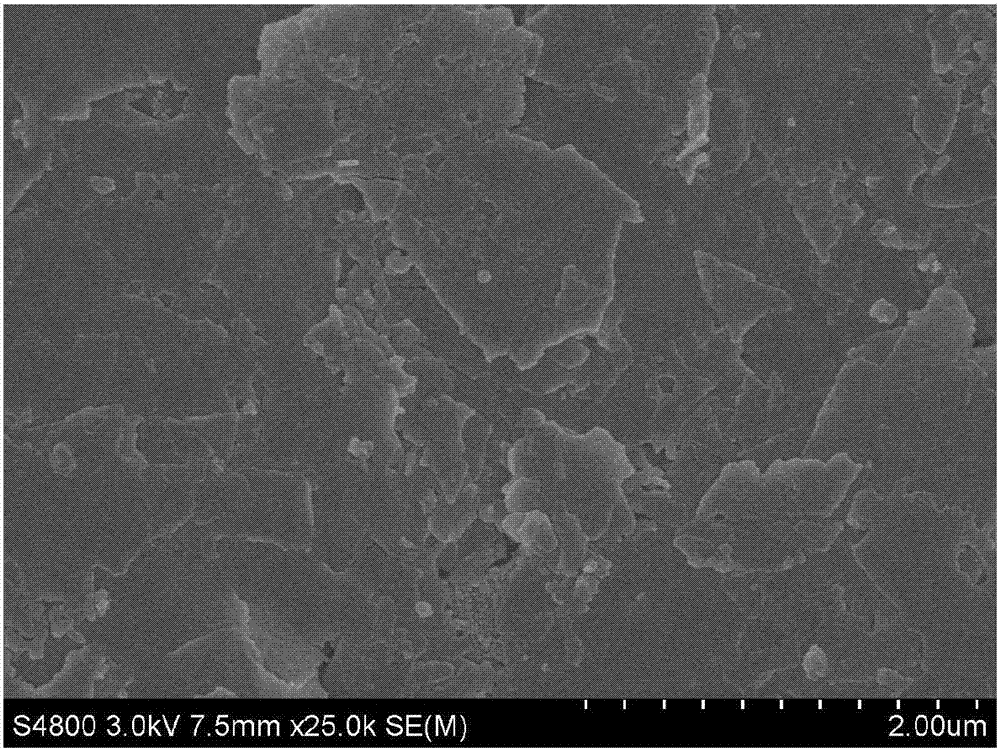

[0024] Step 2: Mix solution B and solution C according to the volume ratio of 1:2, mix and stir for 8 minutes, then move to the reaction kettle, seal it, and conduct a hydrothermal reaction at 160°C for 5 hours. After the reaction, the product is vacuum filtered and washed. Dried to obtain magnesium molybdate nanosheets;

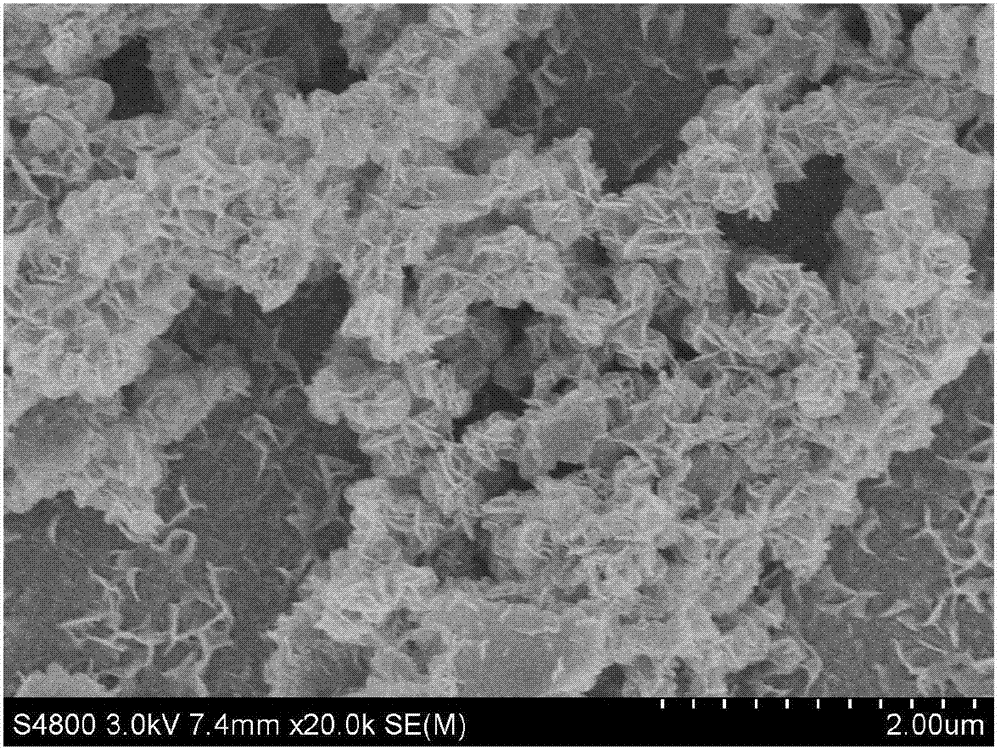

[0025] Step 3: Place the magnesium molybdate nanosheets at 1000° C. for 3 minutes at a constant temperature in an air atmosphere, and then quickly take them out and put them in deionized water at 20° C. to obtain 3D micro-nano curdled ma...

Embodiment 2

[0030] Step 1: P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer) aqueous solution A that configuration concentration is 0.03 mol / liter, magnesium chloride hexahydrate and ethylene glycol are according to mass ratio 20 : 2 mixed and formulated into solution B, sodium molybdate dihydrate and aqueous solution A are mixed and formulated into solution C according to mass ratio 10:1;

[0031] Step 2: Mix and stir solution B and solution C for 10 minutes according to the volume ratio of 1:1, then move to the reaction kettle, seal it, and react hydrothermally at 180°C for 3 hours. After the reaction, the product is vacuum filtered and washed. Dried to obtain magnesium molybdate nanosheets;

[0032] Step 3: After calcining the magnesium molybdate nanosheets at 600°C and constant temperature in an air atmosphere for 30 minutes, quickly take them out and put them into deionized water at 25°C to obtain 3D micro-nano curd magnesium molybdate.

Embodiment 3

[0034] Step 1: P123 (polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer) aqueous solution A that configuration concentration is 0.05 mol / liter, magnesium chloride hexahydrate and ethylene glycol are according to mass ratio 40 : 3 mixed and formulated into solution B, sodium molybdate dihydrate and aqueous solution A are mixed and formulated into solution C according to mass ratio 20:3;

[0035] Step 2: Mix and stir solution B and solution C for 5 minutes according to the volume ratio of 1:3, then move to the reaction kettle, seal it, and conduct a hydrothermal reaction at 200°C for 7 hours. After the reaction, the product is vacuum filtered and washed. Dried to obtain magnesium molybdate nanosheets;

[0036] Step 3: After calcining the magnesium molybdate nanosheets at 800° C. under an air atmosphere at a constant temperature for 15 minutes, quickly take them out and put them in deionized water at 18° C. to obtain 3D micro-nano curdled magnesium molyb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com