Modified polyvinyl alcohol packaging film and preparation method thereof

A polyvinyl alcohol and packaging film technology, applied in the field of film packaging materials, can solve the problems of inconvenient film production and storage, low tensile strength, low modulus, poor heat resistance, etc., achieve low raw material cost, excellent gas barrier performance, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

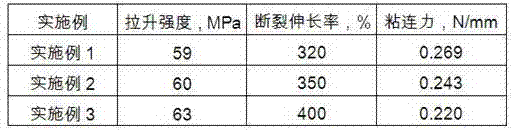

Examples

Embodiment 1

[0022] Embodiment 1 of the present invention provides a modified polyvinyl alcohol packaging film, which consists of the following components in parts by weight: 5 parts of polyvinyl alcohol resin, 15 parts of starch, 0.05 parts of nano zinc oxide, SiO 2 0.5 parts, 0.8 parts of anti-blocking agent, 0.05 parts of Tween 80, 0.02 parts of coupling agent, 0.5 parts of plasticizer, 0.1 part of antioxidant, 0.05 parts of boric acid, 0.01 part of defoamer and 40 parts of deionized water.

[0023] SiO 2 for modified SiO 2 , modified SiO 2 It is obtained by surface grafting of polyetheramine and silica.

[0024] Anti-blocking agent is magnesium stearate

[0025] The coupling agent is a titanate coupling agent.

[0026] The plasticizer is glycerin.

[0027] The defoamer is water-based silicone oil.

[0028] In addition, this embodiment also provides a method for preparing a modified polyvinyl alcohol packaging film, comprising the following steps:

Embodiment 2

[0036] Embodiment 2 of the present invention provides a modified polyvinyl alcohol packaging film, which consists of the following components by weight: 50 parts of polyvinyl alcohol resin, 25 parts of starch, 0.3 parts of nano-zinc oxide, SiO 2 5 parts, 6 parts of anti-blocking agent, 3 parts of Tween 80, 4 parts of coupling agent, 9 parts of plasticizer, 0.4 part of antioxidant, 0.5 part of boric acid, 0.1 part of defoamer and 100 parts of deionized water.

[0037] SiO 2 for modified SiO 2 , modified SiO 2 It is obtained by surface grafting of polyetheramine and silica.

[0038] Antiblocking agent calcium stearate.

[0039] The coupling agent is a titanate coupling agent.

[0040] The plasticizer is trioctyl phosphate.

[0041] The defoamer is n-butanol.

[0042] In addition, this embodiment also provides a method for preparing a modified polyvinyl alcohol packaging film, comprising the following steps:

[0043] (1) Nano-zinc oxide and modified SiO 2 Add it into dei...

Embodiment 3

[0050] Embodiment 3 of the present invention provides a modified polyvinyl alcohol packaging film, which consists of the following components in parts by weight: 27 parts of polyvinyl alcohol resin, 20 parts of starch, 0.17 parts of nano-zinc oxide, SiO 2 2.7 parts, 3.4 parts of antiblocking agent, 1.5 parts of Tween 80, 2 parts of coupling agent, 4.8 parts of plasticizer, 0.25 part of antioxidant, 0.27 part of boric acid, 0.05 part of defoamer and 70 parts of deionized water.

[0051] SiO 2 for modified SiO 2 , modified SiO 2 It is obtained by surface grafting of polyetheramine and silica.

[0052] The antiblocking agent is calcium stearate.

[0053] The coupling agent is a titanate coupling agent.

[0054] The plasticizer is trioctyl phosphate.

[0055] The defoamer is tributyl phosphate.

[0056]In addition, this embodiment also provides a method for preparing a modified polyvinyl alcohol packaging film, comprising the following steps:

[0057] (1) Nano-zinc oxide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com