Gallate red fluorescent powder for white light LED as well as preparation method thereof

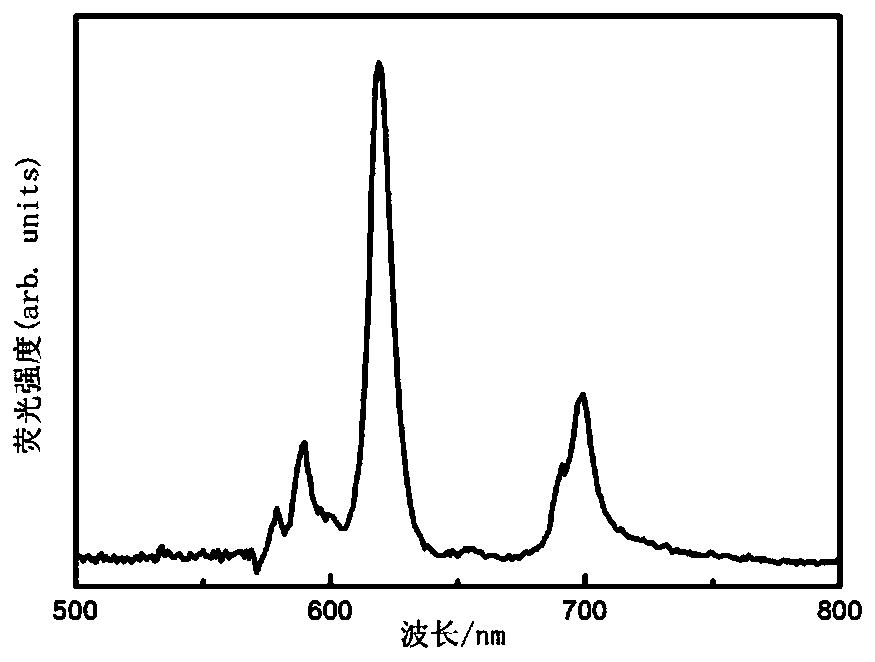

A technology of red phosphor and gallate, applied in the field of gallate red phosphor and its preparation, can solve the problems of unsatisfactory color rendering and color temperature value, lack of red light part, low color rendering index of white LED, etc., to achieve The preparation process is simple, the chemical stability is good, and the effect of high luminous intensity is

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

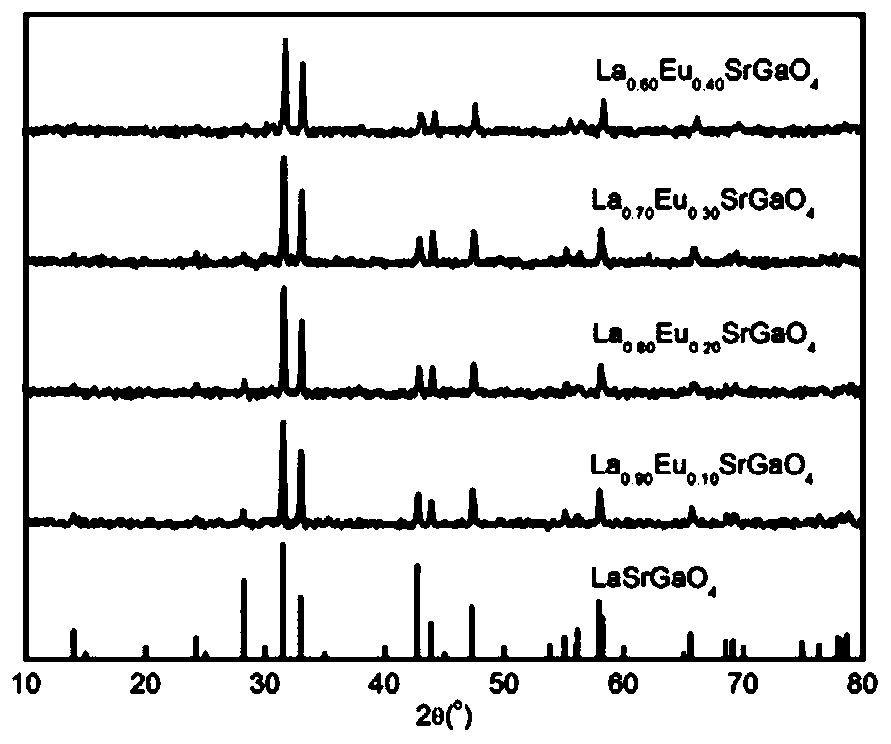

[0034] A kind of gallate red phosphor powder for white light LED, its general chemical formula is La 0.8 Eu 0.2 SrGaO 4 , the preparation method is as follows:

[0035] S1. Prepare 0.01mol sample, weigh lanthanum oxide La 2 o 3 : 1.3033g, strontium carbonate SrCO 3 : 1.4912g, gallium oxide Ga 2 o 3 : 0.9372g, europium oxide Eu 2 o 3 : 0.3519g; fully grind and mix to obtain mixed powder;

[0036] S2. Put the mixed powder in a corundum crucible, put it into a muffle furnace for sintering under oxidation conditions, the sintering temperature is 1400°C, the heating rate is 10°C / min, and the sintering time is 8 hours; after natural cooling to room temperature, The obtained product is taken out, and the gallate red phosphor powder can be obtained after grinding.

Embodiment 2

[0038] The general chemical formula of the gallate red phosphor powder used for white light LED in this embodiment is La 0.9 Eu 0.1 SrGaO 4 , the preparation method is as follows:

[0039] S1. Prepare 0.01mol sample, weigh lanthanum oxide La 2 o 3 : 1.4462g, strontium carbonate SrCO 3 : 1.4912g, gallium oxide Ga 2 o 3 : 0.9372g, europium oxide Eu 2 o 3 : 0.1759g; fully grind and mix to obtain mixed powder;

[0040] S2. Put the mixed powder in a corundum crucible, put it into a muffle furnace for sintering under oxidation conditions, the sintering temperature is 1300°C, the heating rate is 8°C / min, and the sintering time is 4 hours; after natural cooling to room temperature, The obtained product is taken out, and the gallate red phosphor powder can be obtained after grinding.

Embodiment 3

[0042] The general chemical formula of the gallate red phosphor powder used for white light LED in this embodiment is La 0.7 Eu 0.3 SrGaO 4 , the preparation method is as follows:

[0043] S1. Prepare 0.01mol sample, weigh lanthanum oxide La 2 o 3 : 1.1404g, strontium carbonate SrCO 3 : 1.4912g, gallium oxide Ga 2 o 3 : 0.9372g, europium oxide Eu 2 o 3 : 0.5278g; fully grind and mix to obtain mixed powder;

[0044] S2. Put the mixed powder in a corundum crucible, put it into a muffle furnace for sintering under oxidation conditions, the sintering temperature is 1450°C, the heating rate is 7°C / min, and the sintering time is 10 hours; after natural cooling to room temperature, The obtained product is taken out, and the gallate red phosphor powder can be obtained after grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com