Concave pit lithium ion battery current collector as well as manufacturing method and equipment of concave pit lithium ion battery current collector

A lithium-ion battery and current collector technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of large equipment investment, complex process, and large environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

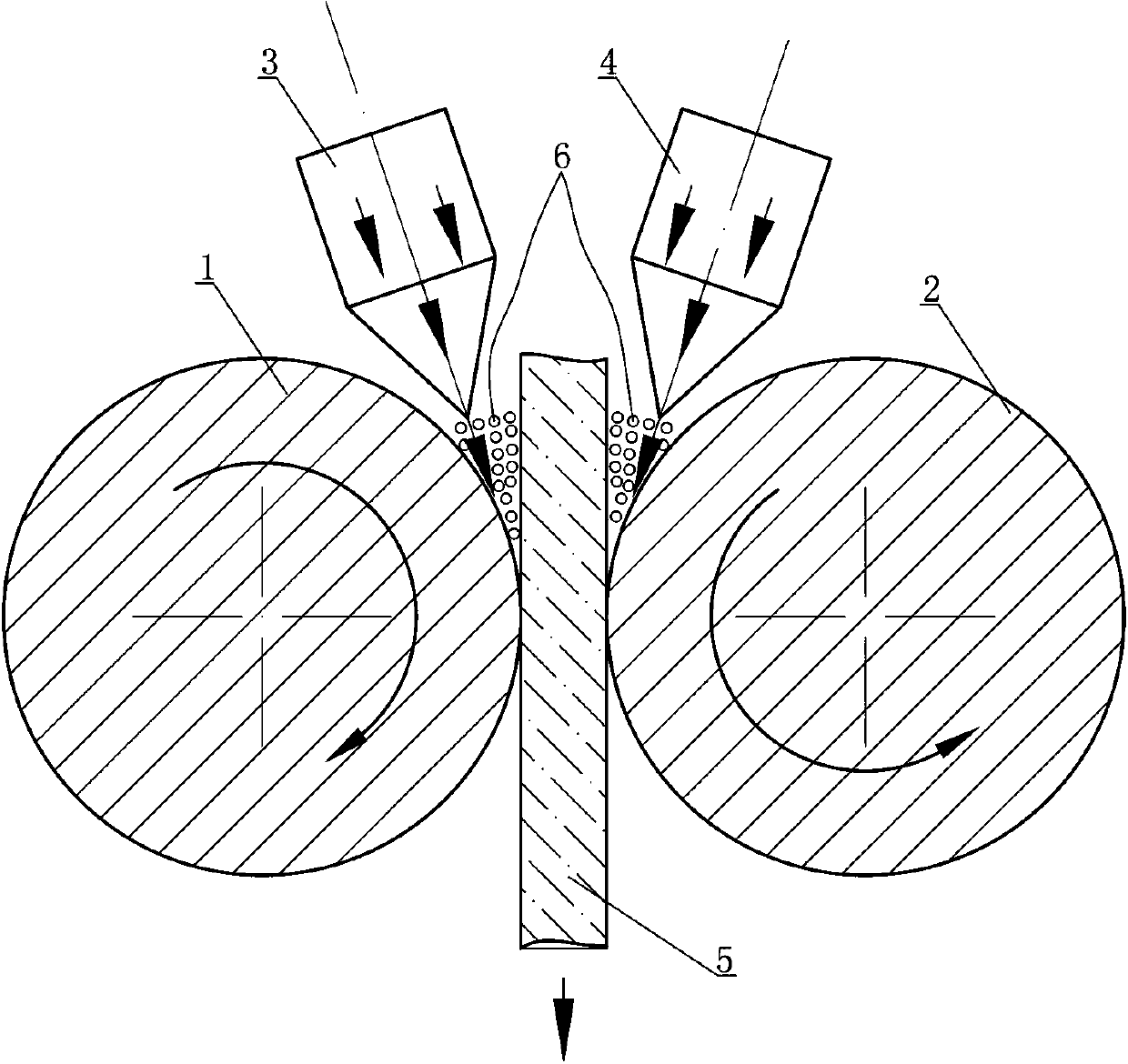

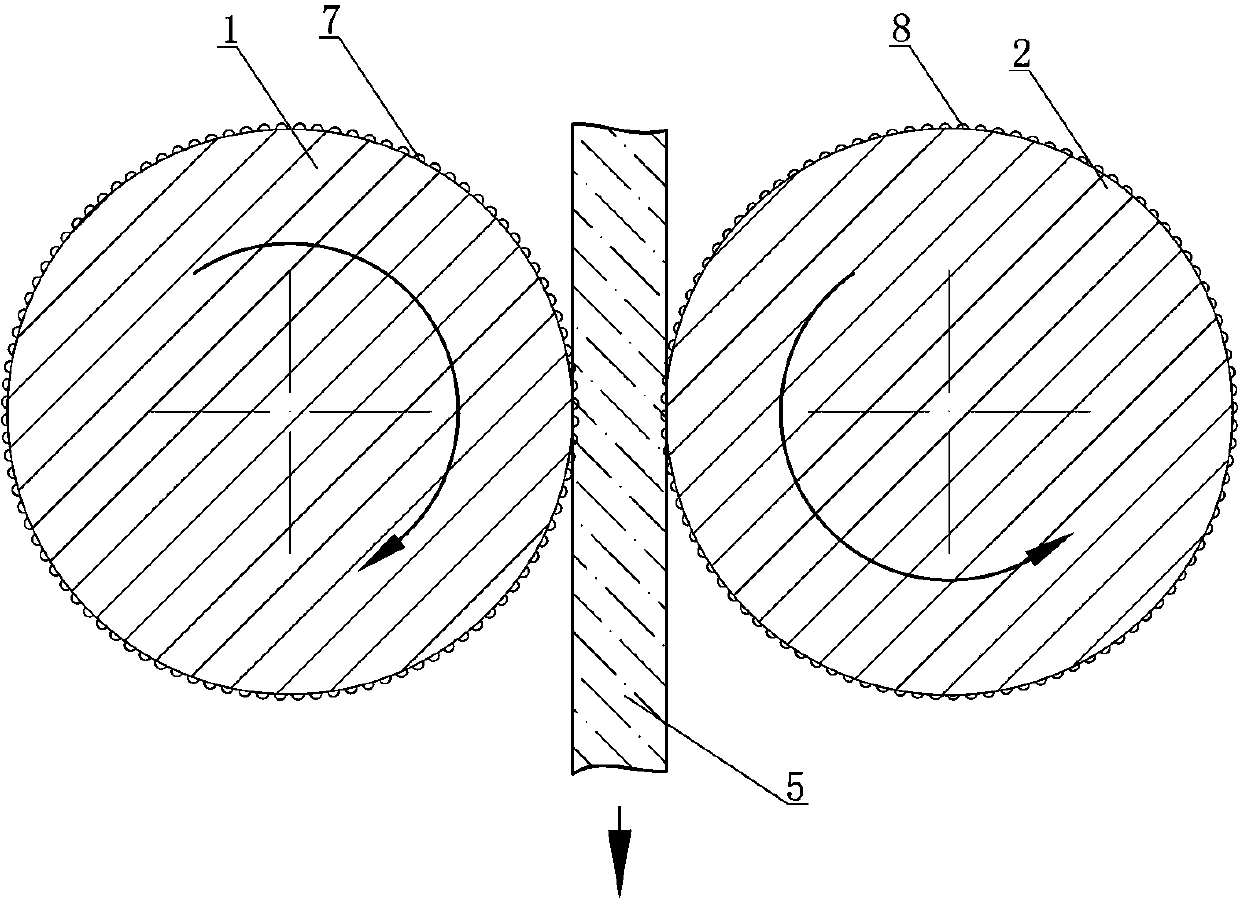

[0033] See figure 1 , the present invention discloses a pitted lithium-ion battery current collector, at least one side of the current collector 5 is provided with pits, and the pits are formed during the process of rolling the current collector by two rolls . figure 1 Among them, the process of the current collector 5 being double-rolled is: when the current collector 5 passes through the rolling station between the left-hand roll 1 and the right-hand roll 2, the left-hand sand filling above the left-hand roll 1 The bucket 2 is filled with particles 6 whose hardness is greater than that of the current collector material between the current collector 5 and the left-hand roll 1. With the extrusion of the left-hand roll 1, the particles 6 form a left side on the left side of the current collector 5. Pit; Certainly, also can or simultaneously the right-hand sand filling bucket 4 above right-hand roll 2 fills the particle 6 that hardness is greater than current collector material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com