Double-layer phase-change microcapsules and production method and application thereof

A phase-change microcapsule and double-layer technology, which is applied in the field of asphalt manufacturing, can solve the problems of phase-change material volatilization and single-layer microcapsules are easy to break, and achieve enhanced high-temperature stability, good mechanical properties and thermal stability, and reduced Effect of rut depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

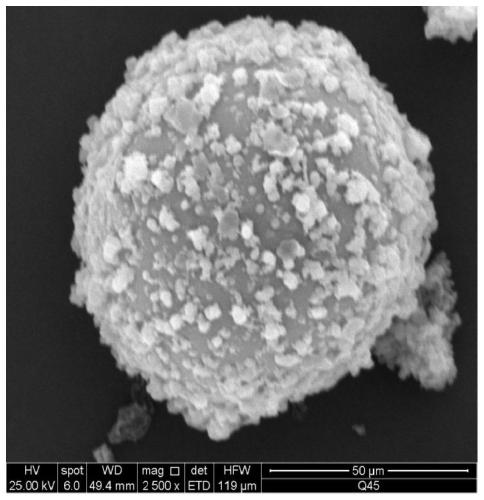

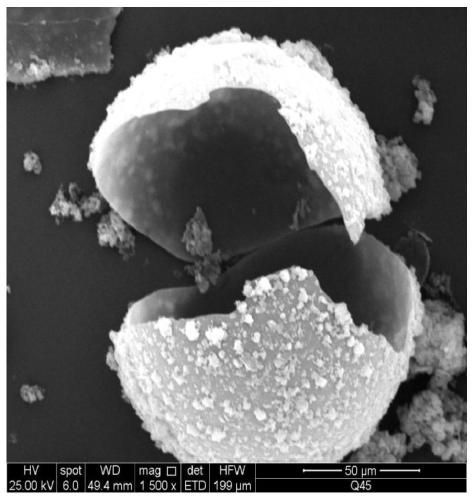

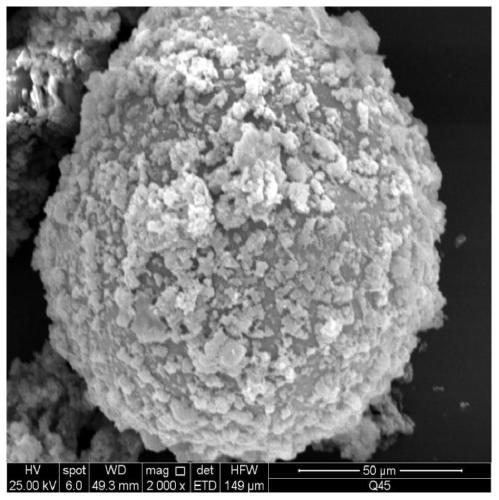

Image

Examples

Embodiment 1

[0028] In terms of parts by mass, weigh 6 parts of single-layer phase change microcapsules, add 15 parts of pure water, and stir evenly.

[0029] Then heat the prepared solution to 70°C, add 0.8 parts of Tween 80, 0.6 parts of boric acid and 3 parts of zinc chloride solution, then drop in 5% sodium hydroxide solution to adjust the pH to 7, wait for 0.5 hours of heat preservation reaction, filter , washing and drying to obtain zinc borate double-layer phase change microcapsules.

Embodiment 2

[0031] In terms of parts by mass, 10 parts of single-layer phase change microcapsules were weighed, 22 parts of pure water were added, and stirred evenly.

[0032] Then heat the prepared solution to 75°C, add 1.2 parts of Tween 80, 1 part of boric acid and 3.4 parts of zinc chloride solution, then drop in 5% sodium hydroxide solution to adjust the pH to 8, wait for 0.5 hours of heat preservation reaction, filter , washing and drying to obtain zinc borate double-layer phase change microcapsules.

Embodiment 3

[0034] In terms of parts by mass, 14 parts of single-layer phase change microcapsules were weighed, 27 parts of pure water were added, and stirred evenly.

[0035] Then heat the prepared solution to 80°C, add 1.6 parts of Tween 80, 1.4 parts of boric acid and 4 parts of zinc chloride solution, then drop in 5% sodium hydroxide solution to adjust the pH to 8, wait for 0.5 hours of heat preservation reaction, filter , washing and drying to obtain zinc borate double-layer phase change microcapsules.

[0036] 2. Aluminum hydroxide double-layer phase change microcapsules

[0037] In terms of parts by mass, 6-14 parts of single-layer phase-change microcapsules are weighed, 15-27 parts of pure water are added, and stirred evenly.

[0038] Then heat the prepared solution to 40-50°C, add 0.2-0.6 parts of Tween 80 and 60-80 parts of aluminum nitrate, then add dropwise 5% ammonia solution to adjust the pH to 6-7, wait for 3 hours to keep warm, filter, Washing and drying obtain aluminum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com