Ceramic material, and preparation method and applications thereof

A technology of ceramics and ceramic bodies, applied in the field of refrigeration equipment, can solve the problems of affecting the environment, pollution, and increasing the cost of rolling piston blank castings, and achieve the effects of improving hardness and wear resistance, and improving comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

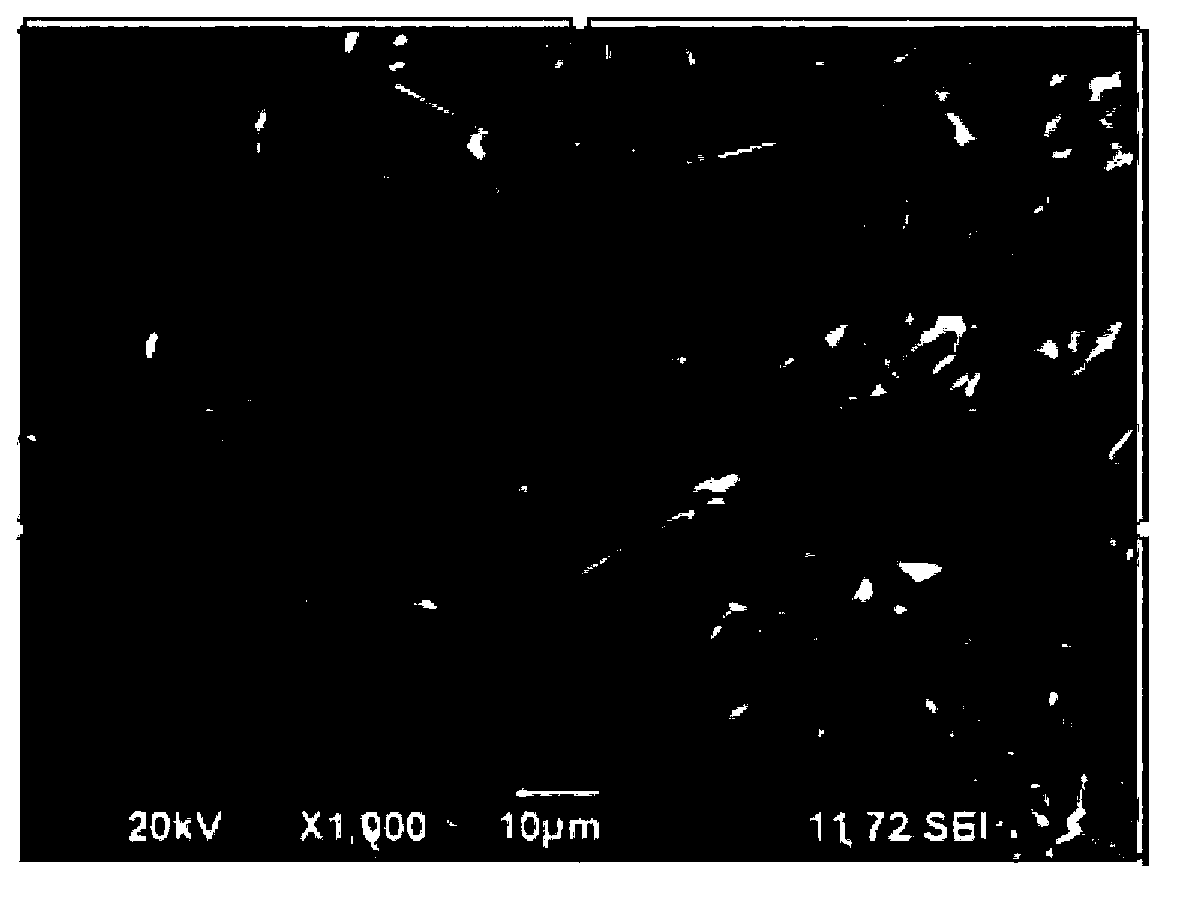

Image

Examples

Embodiment 1

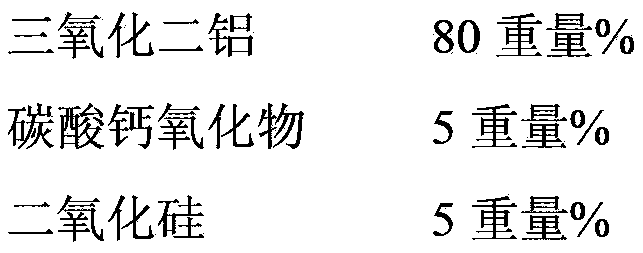

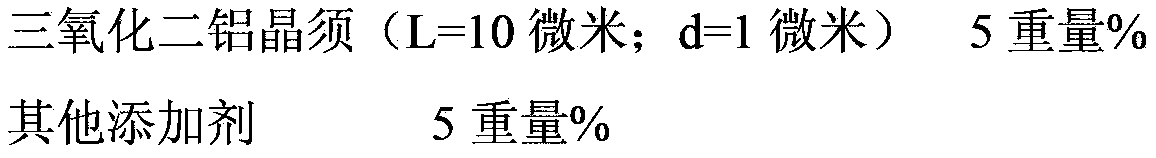

[0038] raw material:

[0039]

[0040]

[0041] First, 80% by weight of aluminum oxide, 5% by weight of calcium carbonate oxide, and 5% by weight of silicon dioxide are mixed and ground, then add 5% by weight of aluminum oxide whiskers (L=10 microns; d=1 micron) and 5% by weight of other additives are mixed together, then cold-pressed, and then the pre-sintered sample in an oxidizing atmosphere is placed in a hot isostatic pressing furnace and filled with

[0042] 100-200MPa inert gas Ar, heat preservation at 1200-1800 degrees Celsius for 2-3 hours for hot isostatic sintering to obtain ceramic pistons, and send the product pistons for inspection.

Embodiment 2

[0044] raw material:

[0045]

[0046] The preparation method is the same as in Example 1, and the product piston is sent for inspection.

Embodiment 3

[0048] raw material:

[0049]

[0050] The preparation method is the same as in Example 1, and the product piston is sent for inspection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com