Beta-FeOOH nanorod and preparation method thereof

A technology of nanorods and hydrolysis reaction, which is applied in the field of inorganic nanomaterials, can solve problems such as complex operation, difficult to reach nanoscale products, and harsh conditions, and achieve the effects of wide sources, uniform shape, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) 0.5mL PEI (polyethyleneimine) was dissolved in 100mL deionized water, and 5.4g (20mmol) of ferric chloride containing six crystal waters was added thereto, and a uniform mixed solution was formed under magnetic stirring, The mixed solution is orange-red.

[0036] (2) The mixed solution in step 1) was placed in a constant temperature oil bath reactor at 80° C., under magnetic stirring, and hydrolyzed for 2 hours.

[0037] (3) The liquid after the hydrolysis reaction was centrifuged and washed three times with deionized water, the yellow precipitate after centrifugation and washing was collected, and the precipitate was ultrasonically dispersed in deionized water to obtain β-FeOOH nanorods.

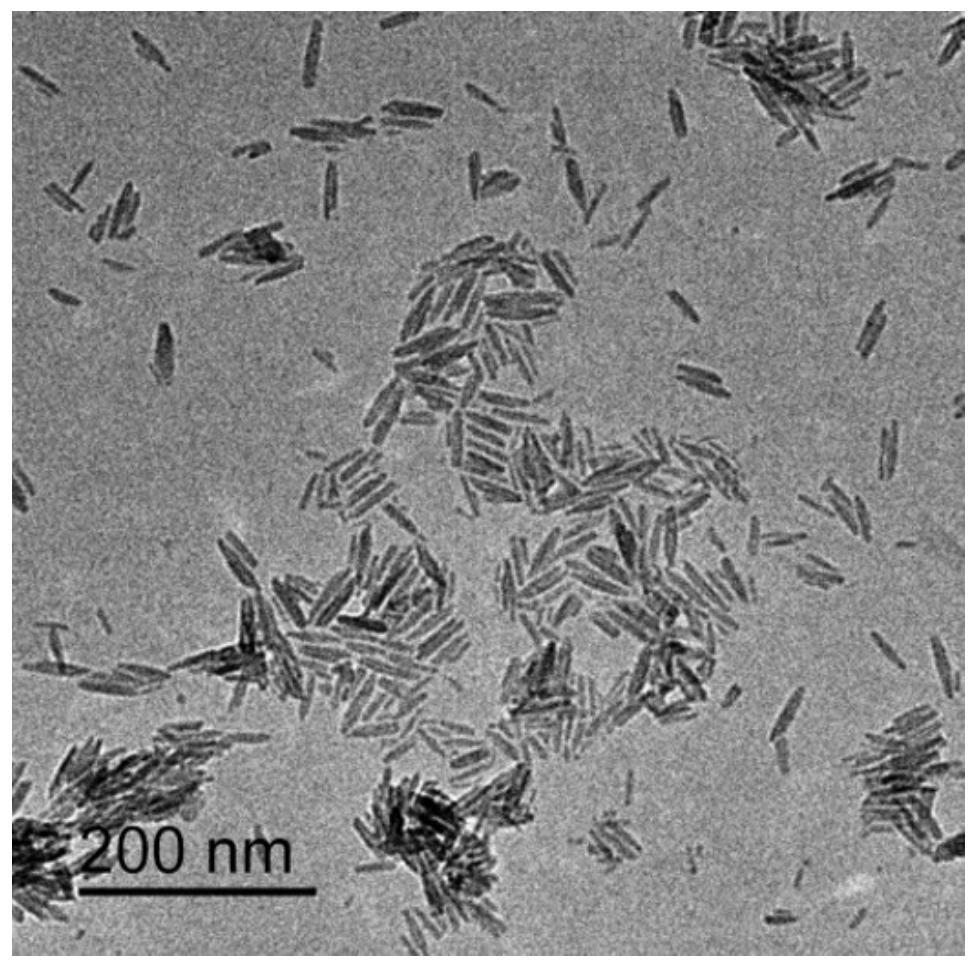

[0038] The morphology of the β-FeOOH nanorods prepared in this example was characterized, and the transmission electron microscopy results were as follows: figure 1 shown, from figure 1 It can be seen that the average diameter of β-FeOOH nanorods is about 10 nm and the length i...

Embodiment 2

[0040] (1) 0.3mL PEI was dissolved in 100mL deionized water, and 5.4g (20mmol) ferric chloride containing six crystal waters was added thereto, and magnetically stirred to form a uniform mixed solution, which was orange-red.

[0041] (2) The mixed solution in step 1) was placed in a constant temperature oil bath reactor at 80° C., and hydrolyzed for 2.5 hours under magnetic stirring.

[0042] (3) The liquid after the hydrolysis reaction was centrifuged and washed three times with deionized water, the yellow precipitate after centrifugation and washing was collected, and the yellow precipitate was ultrasonically dispersed in the deionized aqueous solution to obtain β-FeOOH nanorods.

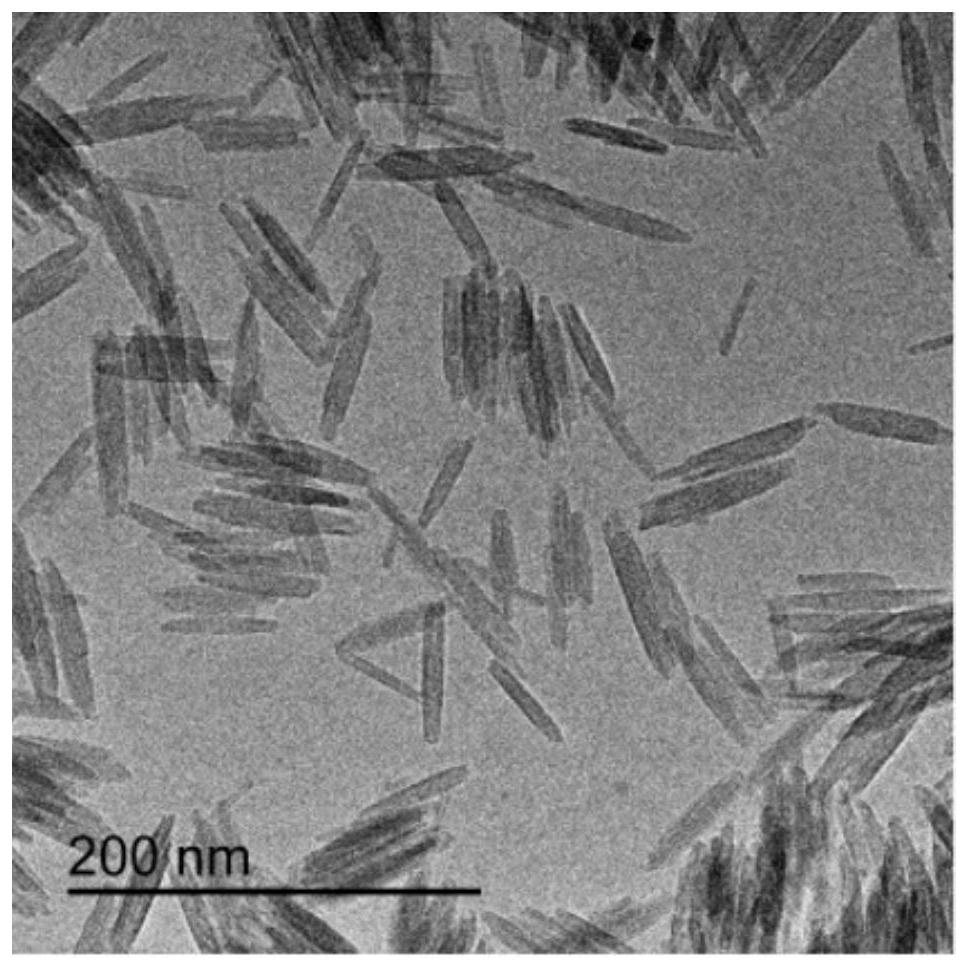

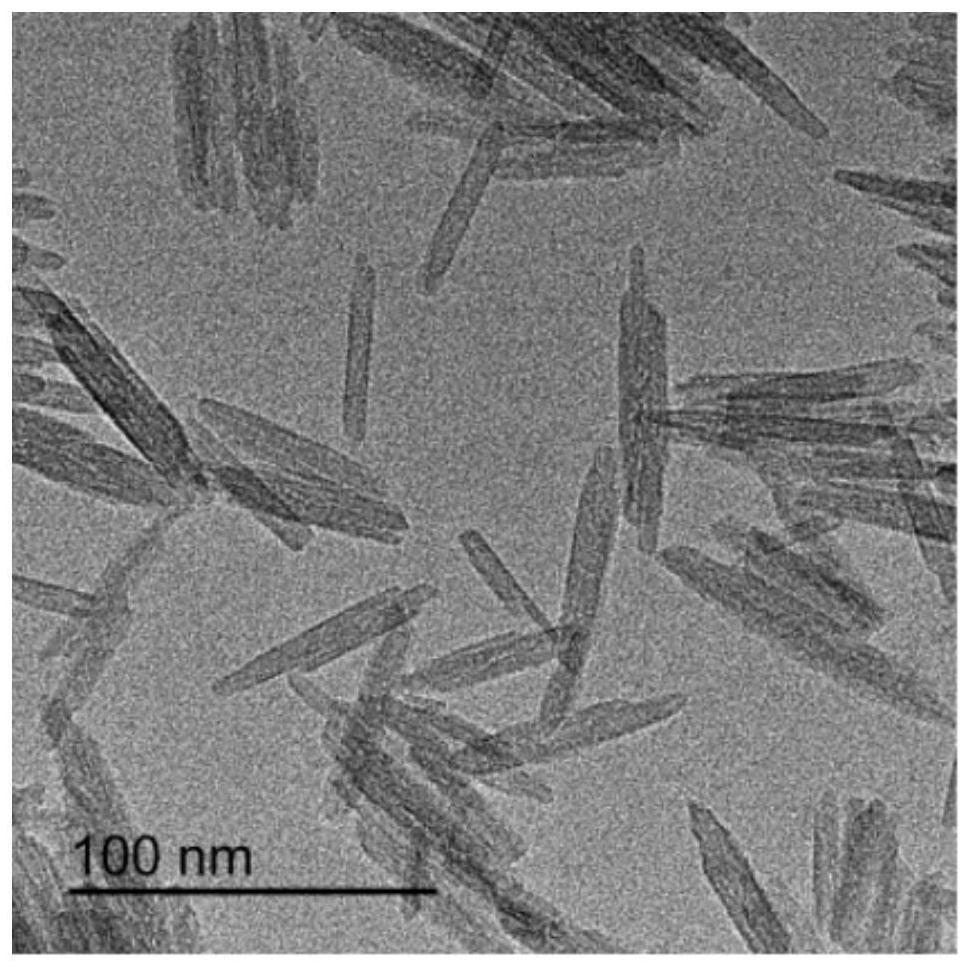

[0043] The morphology of the β-FeOOH nanorods prepared in this example was characterized, and the transmission electron microscopy results were as follows: figure 2 and image 3 as shown, figure 2 The scale bar is 200nm, image 3 The scale bar is 100nm, from figure 2 and image 3 It can be...

Embodiment 3

[0045] (1) 1.0mL PEI was dissolved in 100mL deionized water, and 5.4g (20mmol) ferric chloride containing six crystal waters was added thereto, and magnetically stirred to form a uniform mixed solution, which was orange-red.

[0046] (2) The mixed solution in step 1) was placed in a constant temperature oil bath reactor at 85° C., and hydrolyzed for 2 hours under magnetic stirring.

[0047] (3) The liquid after the hydrolysis reaction was centrifuged and washed four times with deionized water, and the yellow precipitate after centrifugation and washing was collected, and the yellow precipitate was ultrasonically dispersed in the deionized aqueous solution to obtain β-FeOOH nanorods.

[0048] The β-FeOOH nanorods obtained in this embodiment were characterized by a transmission electron microscope, and the result was: the diameter of the β-FeOOH nanorods was about 10 nm, and the length was 50±5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com