Plastic floor mat and manufacturing method thereof

A technology of plastic and plastic film, which is applied in the direction of carpets, etc., can solve the problems of difficult to obtain high-quality patterns, increase costs, and difficult cleaning, etc., and achieve the effect of being suitable for large-scale production, simplifying the production process, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

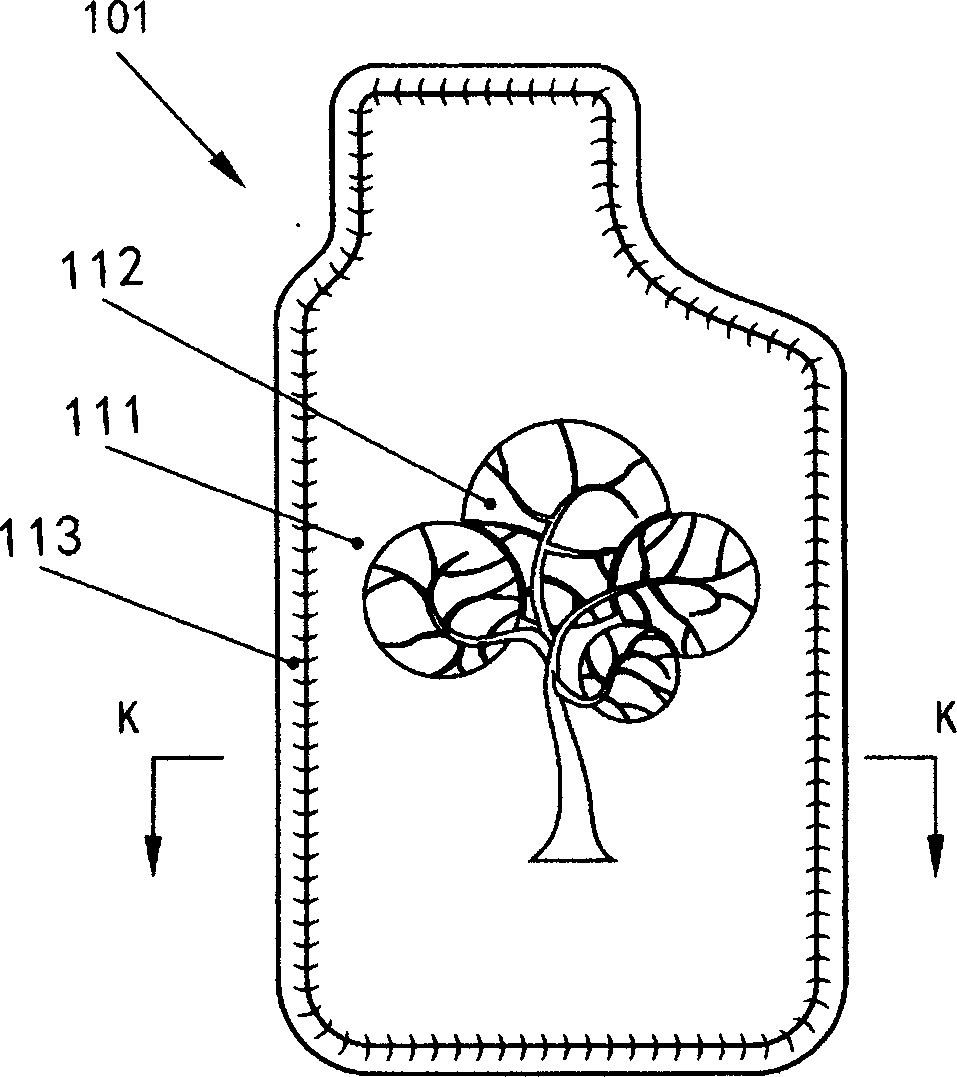

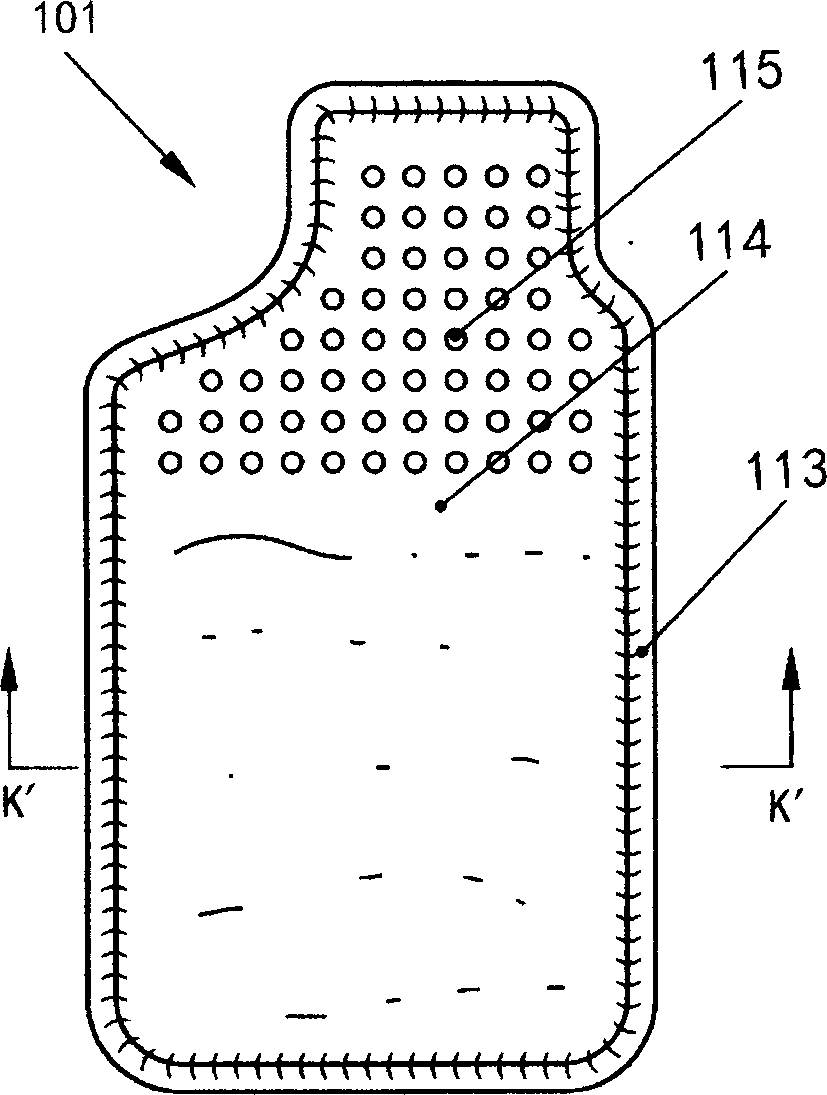

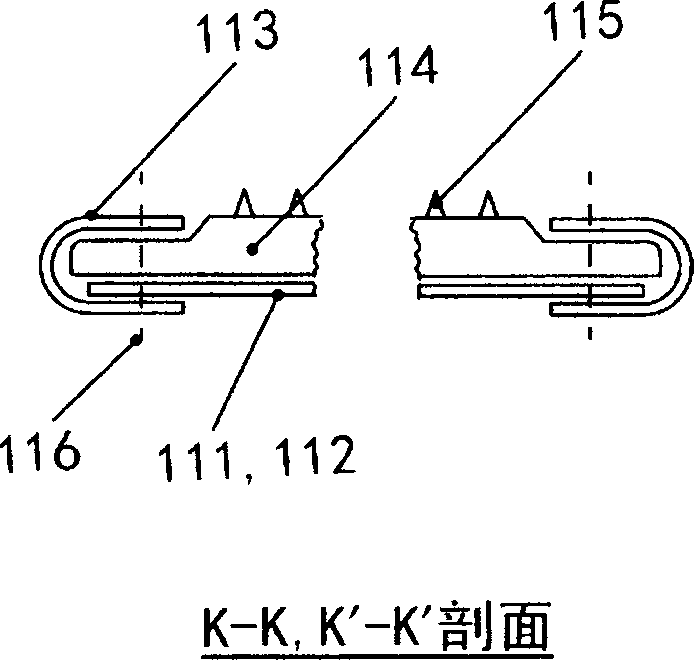

[0026] 2(a) to 2(e) show the detailed structure of the plastic floor mat of the present invention. In the figure, numeral 1 denotes the plastic floor mat of the present invention. Reference numeral 2 represents the surface sheet of the plastic film, and the reference numeral 12 represents the art pattern or text printed on the back side of the plastic film (i.e. non-pedal, towards the side of the main sheet 14 below it), because the plastic film is transparent or Translucent, these artwork or text can be seen from the front. Therefore, the dough sheet 2 includes the plastic film 11 itself and the artistic patterns or characters 12 printed thereon. Reference numeral 14 represents the main body of the floor mat, which is formed by injection molding of plastics. The number 15 represents the anti-skid bumps that are injection-molded on the bottom surface of the floor mat main body 14. When laying on the ground or the floor, it increases friction or resistance. Hysteresis (these ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com