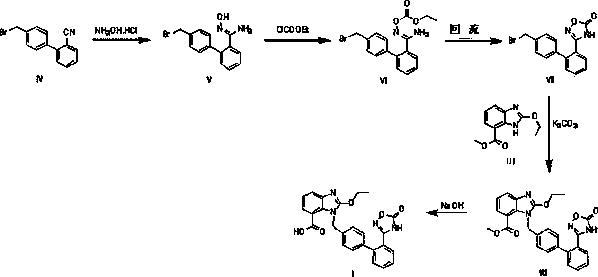

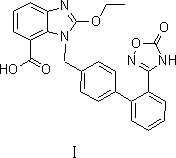

Novel preparation method for azilsartan and intermediate thereof

An intermediate, bromomethyl technology, applied in the field of preparation of pharmaceutical compounds, can solve problems such as instability of the 2-position ethoxy group, difficulty in product purification, and carbonyl conversion, and achieve easy procurement, industrial mass production, and route shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

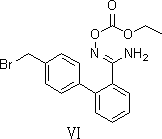

[0044] example 1( Z )-4'-(bromomethyl)- N’ Preparation of -Hydroxy-[1,1'-biphenyl]-2-amidine

[0045] Add 100ml of dimethyl sulfoxide to the dry reaction bottle, add 182g of hydroxylamine hydrochloride, stir to dissolve, add 60g of raw material 2-cyano-4'-bromomethylbiphenyl, control the internal temperature at 25-30°C, add 302g of anhydrous sodium carbonate, heat up to 75-80°C, keep warm for reaction, and use HPLC to control (until 2-cyano-4'-bromomethylbiphenyl≤0.5%). Cool down to 20-30°C, slowly add 3L of water, and continue stirring for 1 hour after the addition is complete. Suction filtration, the filter cake was washed with about 200ml of water, suction filtration to dryness, and drying under reduced pressure at 50±5°C to obtain ( Z )-4'-(bromomethyl)- N’ -Hydroxy-[1,1'-biphenyl]-2-amidine dry product 57g. Yield 85.4%, purity 96.7%.

example 2

[0046] Example 2 ( Z )-4'-(bromomethyl)- N’ Preparation of -Hydroxy-[1,1'-biphenyl]-2-amidine

[0047] Add 69.5g of hydroxylamine hydrochloride to 400ml of tetrahydrofuran and stir to dissolve, add dropwise 210g of 27% sodium methoxide in methanol at room temperature, stir for 10 minutes, add 54.2g of 2-cyano-4'-bromomethylbiphenyl, at 90 Stir the reaction at ~95°C, use HPLC to control (until 2-cyano-4'-bromomethylbiphenyl≤0.5%), cool down to 20-30°C, add 1.2L water dropwise at room temperature, and stir for 30 minutes. Filter, wash with 100°C of water, and dry under reduced pressure at 50-60°C to obtain ( Z )-4'-(bromomethyl)- N’ -Hydroxy-[1,1'-biphenyl]-2-amidine dry product 54.6g, yield 89.9%, purity 95.8%

example 3

[0048] Example 3 ( Z )-4'-(bromomethyl)- N’ Preparation of -Hydroxy-[1,1'-biphenyl]-2-amidine

[0049] Add 139g of hydroxylamine hydrochloride to 750ml of ethanol and stir to dissolve, add dropwise 220g of triethylamine at room temperature, stir at 35~40 for 60 minutes, add 66g of 2-cyano-4'-bromomethylbiphenyl, and stir at 65~70 The reaction was controlled by HPLC (until 2-cyano-4'-bromomethylbiphenyl≤0.5%), cooled to room temperature, 2L water was added dropwise at room temperature, stirred for 1h, filtered, washed with 150ml water, at 50 ~60 decompression drying, get ( Z )-4'-(bromomethyl)- N’ -Hydroxy-[1,1'-biphenyl]-2-amidine dry product 59.2g, yield 79.8%, purity 96.4%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com