Optical fiber rotary connector

A technology for rotating connectors and connectors, applied in the directions of light guides, optics, instruments, etc., can solve problems such as restricting popularization and application, and achieve the effects of reducing volume, reducing quality, and increasing the density of fiber channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

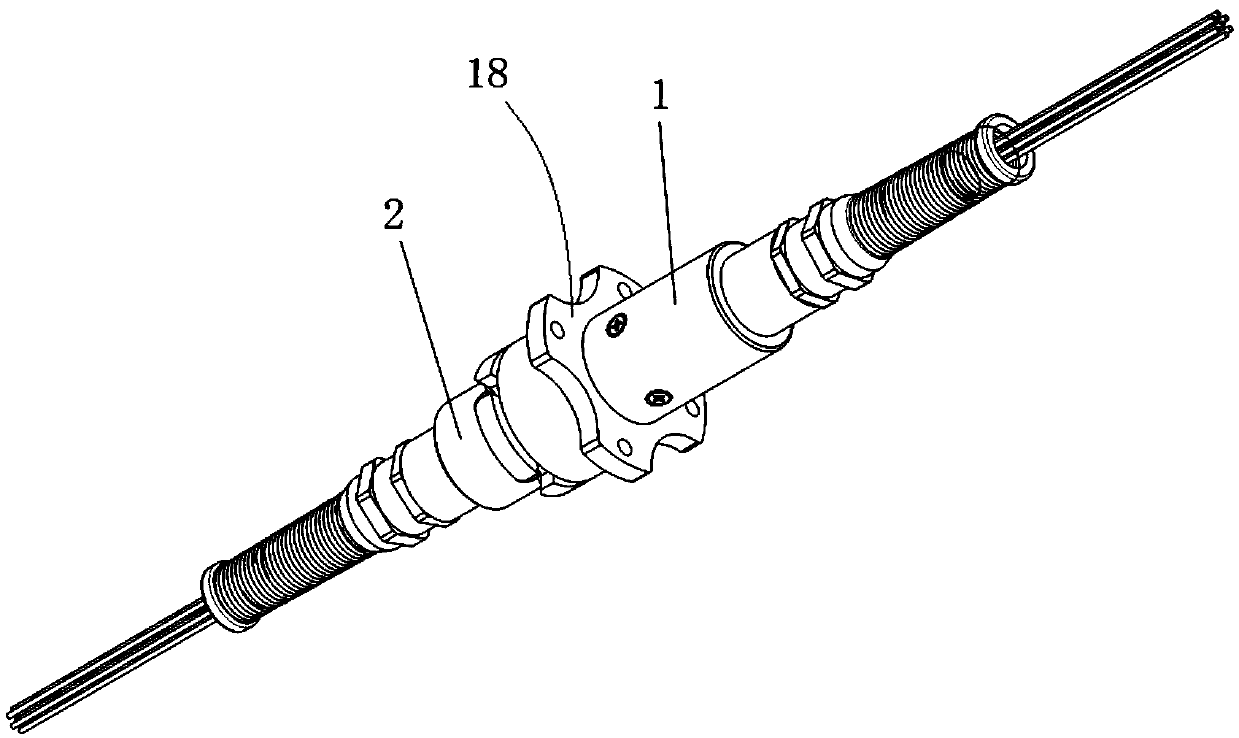

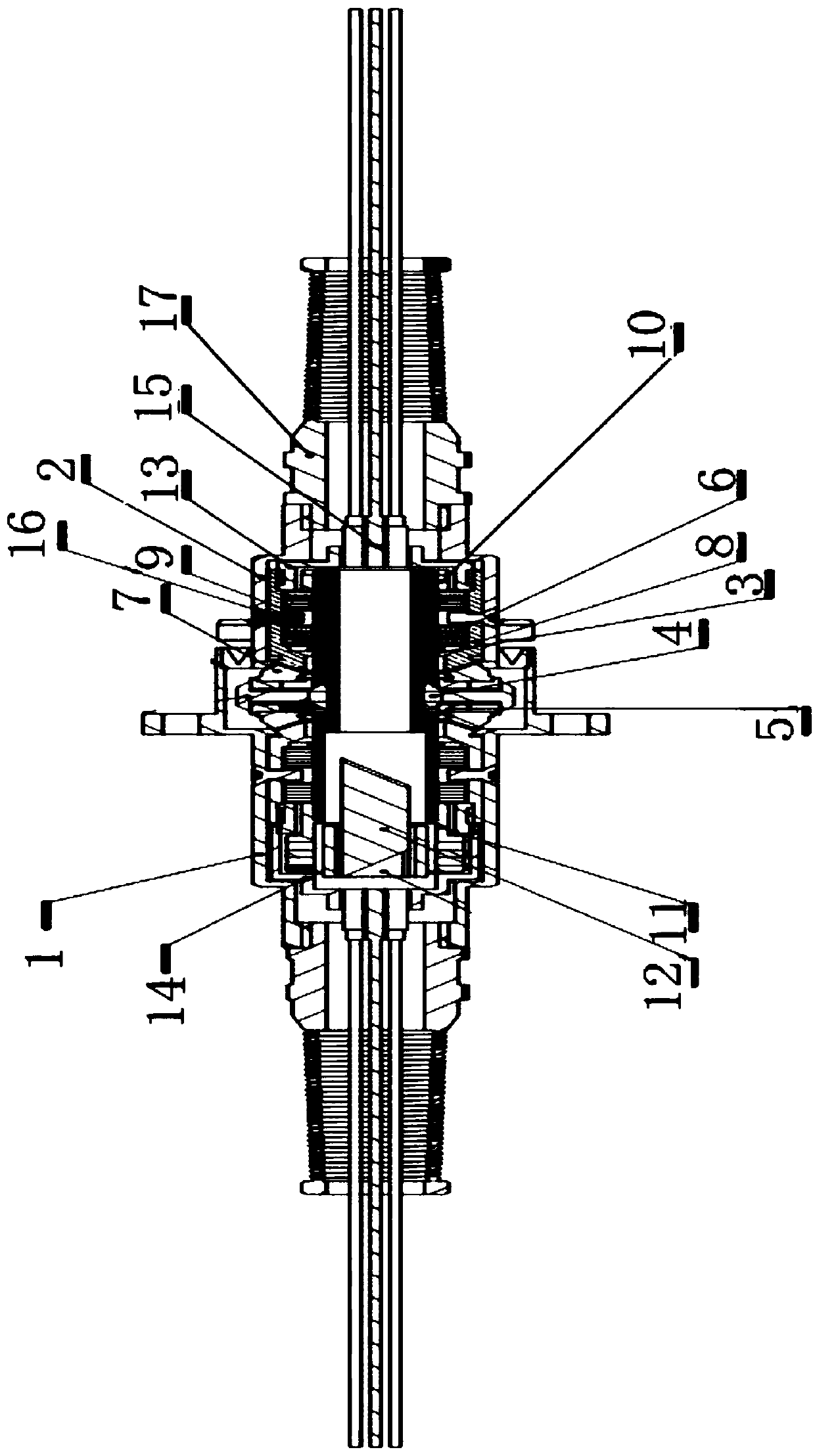

[0013] like Figure 1-Figure 2 As shown, a fiber optic rotary connector includes a connector housing 18, the connector housing 18 includes a stator housing 1 and a rotor housing 2, and the stator housing 1 and the rotor housing 2 are provided with connected hollows. Cavity, the sun shaft 3 and the planet shaft 4 are arranged in the cavity, and the sun shaft 3 and the planet shaft 4 are fixed by screw connection, and the planet shaft 4 has an upper sleeve part and a The lower socket part, the upper socket part and the lower socket part are provided with a planetary bearing 5, the sun shaft 3 is provided with a sun bearing 6, and the planetary bearing 5 is provided with a planetary gear 7 , the sun bearing 6 is provided with a sun gear 8, the planetary gear 7 is meshed with the sun gear 8, the sun shaft 3 is provided with a bushing 9, and the outer end of the sun shaft 3 is provided with The inner ring locking ring 10, and the other end of the sun shaft 3 is provided with a pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com