Production method of high-purity nanocrystalline silicon

A technology of nanocrystalline silicon and its production method, which is applied in the production of high-purity nanocrystalline silicon and the field of producing nanocrystalline silicon, can solve the problems of difficult industrial production, poor stability, and high cost, and achieve prevention of re-agglomeration, small particle size, and energy saving The effect of investment fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

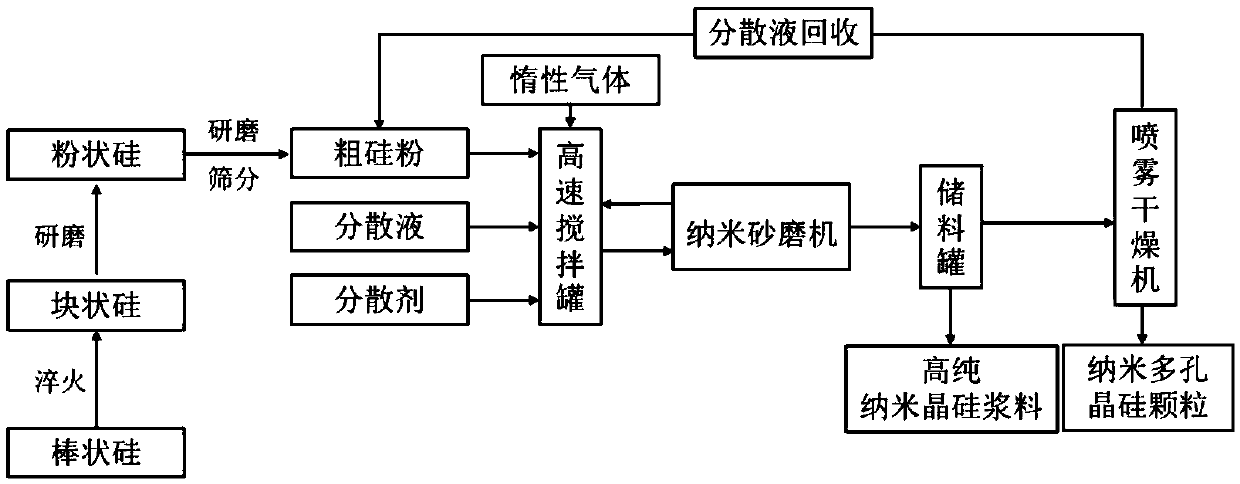

[0060] A kind of production method of high-purity nanocrystalline silicon of the present invention specifically comprises the following steps:

[0061] 1) Select high-purity rod-shaped silicon waste, quench and crush, sieve, and grind to obtain high-purity silicon powder <50 μm.

[0062] 2) Send the silicon powder, dispersion liquid, and dispersant to the stirring tank through the conveying pipeline and stir evenly at high speed, wherein the solid content is 30%, the dispersant is 10 wt%, the rotational speed is 1500 r / min, and the pre-stirring time is 15 min, to obtain the silicon powder slurry.

[0063] 3) Transport the silica powder slurry to a 3L nano-sand mill through a pipeline at a feed rate of 5 L / min, with a ball-to-material ratio of 4:1, zirconia beads with a grinding medium particle size of 0.1 mm, and a rotational speed of 1000r / min , and sanded for 24 h to obtain high-purity nanocrystalline silicon slurry. The dispersion liquid is a combination of absolute ethan...

Embodiment 2

[0067] A kind of production method of high-purity nanocrystalline silicon of the present invention specifically comprises the following steps:

[0068] 1) Select high-purity coral material, crush, grind, and sieve to obtain high-purity coarse silica powder <50 μm.

[0069] 2) Send the coarse silicon powder, dispersion liquid and dispersant to the stirring tank through the conveying pipeline and stir evenly at high speed to obtain the silicon powder slurry. Among them, the solid content is 15%, and the dispersant is 5 wt%. The rotation speed is 1800 r / min, and the pre-stirring time is 12 minutes.

[0070] 3) Transport the silicon powder slurry to a 3 L nano-sand mill through a pipeline at a feed rate of 8 L / min, the ball-to-material ratio is 5:1, the particle size of the grinding medium is 0.1 mm zirconia balls, and the speed is 1200r / min, sanding for 12 h to obtain high-purity nanocrystalline silicon slurry. The dispersion liquid is a combination of isopropanol and glyceri...

Embodiment 3

[0074] A kind of production method of high-purity nanocrystalline silicon according to the present invention specifically comprises the following steps:

[0075] 1) Select the by-product silicon powder of granular silicon in the fluidized bed method, carry out sieving and grinding, and prepare high-purity silicon powder of <40 μm;

[0076] 2) Send the silicon powder, dispersion liquid, and dispersant to the stirring tank through the conveying pipeline and stir evenly at high speed to obtain the silicon powder slurry. Among them, the solid content is 10%, the dispersant is 1 wt%, the rotation speed is 2200 r / min, and the pre-stirring time is 5 min.

[0077] 3) Pipeline the silicon powder slurry to a 3L nano-sand mill at a feed rate of 9L / min, the ball-to-material ratio is 8:1, the particle size of the grinding medium is 0.05mm silicon carbide balls, and the speed is 1500r / min. 10 h to obtain high-purity nanocrystalline silicon slurry. The dispersion liquid is a combination of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com