Solar cell and method for manufacturing same

A technology for solar cells and manufacturing methods, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex preparation process of porous silicon, poor shape stability of porous silicon, easy reduction of back reflection effect, etc., and achieve good back field bluntness Improved performance, improved photogenerated current, and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solar cell provided by the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

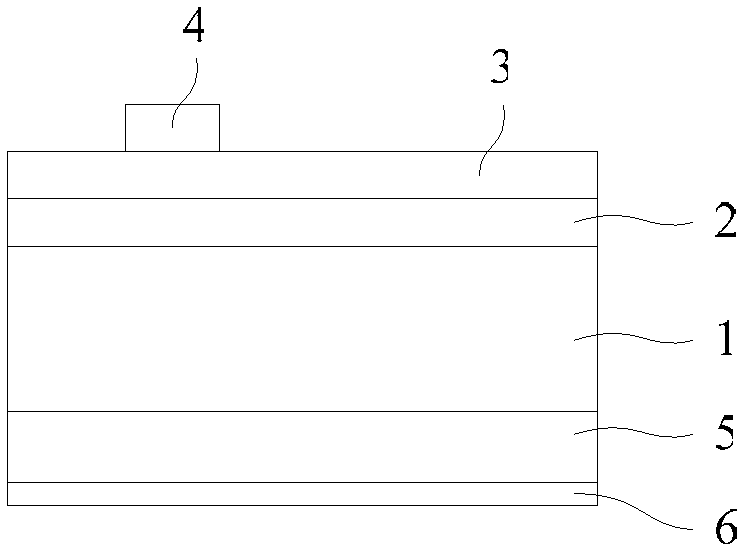

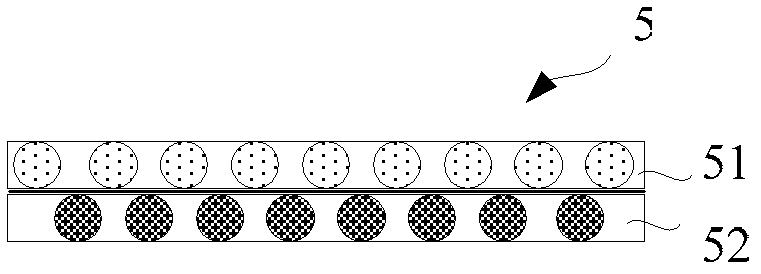

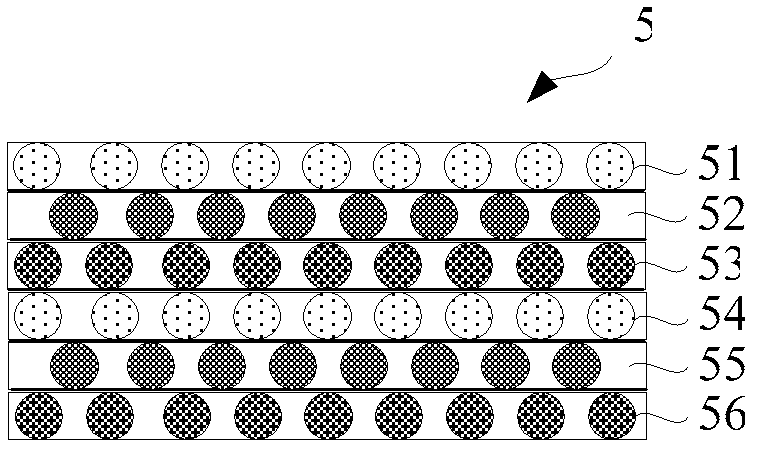

[0038] figure 1 A schematic diagram of the structure of the solar cell provided by the present invention. see figure 1 The solar cell provided in this embodiment includes a silicon substrate 1 , an N-type silicon 2 , an antireflection layer 3 , a front electrode 4 , a back reflection layer 5 and a back electrode 6 . Wherein, the N-type silicon 2 , the anti-reflection layer 3 and the front electrode 4 are sequentially stacked on the light-receiving surface side of the silicon substrate 1 from the silicon substrate 1 . The back reflection layer 5 and the back electrode 6 are sequentially stacked on the backlight side of the silicon substrate 1 from the silicon substrate 1 . Moreover, the silicon subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com