In-plane switching mode liquid crystal display

A liquid crystal display, internal switching technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve problems such as difficult to manufacture products, display color changes, low price competitiveness, etc., and achieve high yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

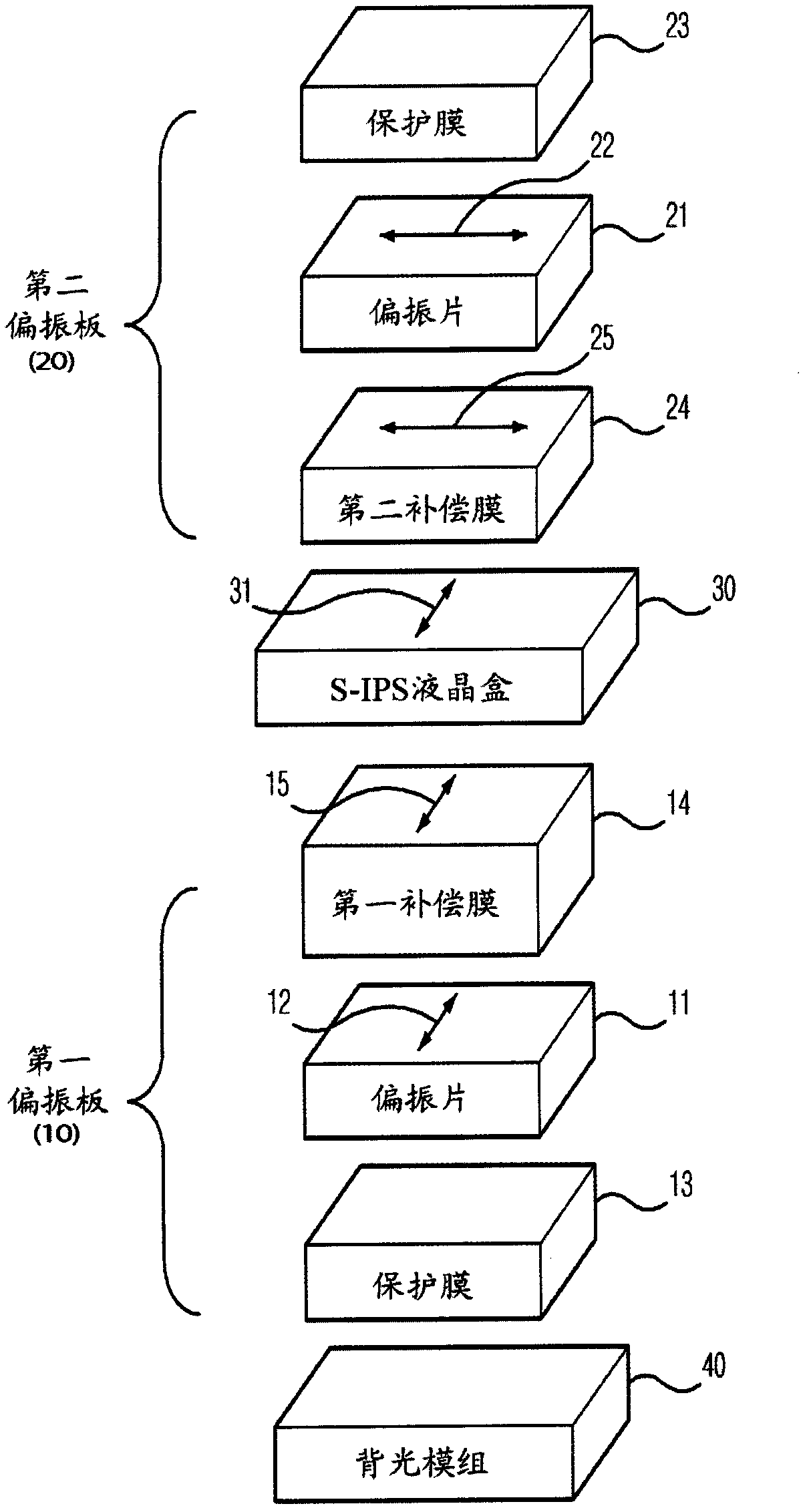

[0089] According to the actual measured data of each optical film of the present invention, liquid crystal cell and backlight module with figure 1 The stacked structure shown was applied to TECH WIZ LCD 1D (Sanayi System Co., Ltd., Korea). described in detail below figure 1 Structure.

[0090] Starting from the backlight module 40 side, the first polarizing plate 10, the in-plane switching mode liquid crystal cell 30 (when the liquid crystal orientation is measured in the counterclockwise direction from the right horizontal direction of the display side under the state where no voltage is applied), the liquid crystal cell has 90° liquid crystal orientation) and a second polarizing plate 20, wherein the first polarizing plate 10 is formed by laminating the first compensation film 14, the polarizing plate 11 and the protective film 13 from the liquid crystal cell 30 side, and the first polarizing plate 10 is formed from the liquid crystal cell 30 side The second polarizing pla...

example 2

[0110] Although the same configuration as in Example 1, the second compensation film 24 has an in-plane retardation (R0) of 200 nm and a refractive index ratio (NZ) of −0.5, and the first compensation film 14 has an in-plane retardation ( R0) and a refractive index ratio (NZ) of -1.1, the second compensation film 24 and the first compensation film 14 are used to manufacture an in-plane switching mode liquid crystal display.

[0111] Depending on the wavelength, the variation of the polarization state in a switch-mode liquid crystal display above the Poincaré sphere is related to Figure 6 Similarly, moreover, the transmittance results for all light directions are the same as Figure 8 same. able to pass Figure 8 Confirm that since the blue portion is wider at the center, a wider viewing angle is ensured.

example 3

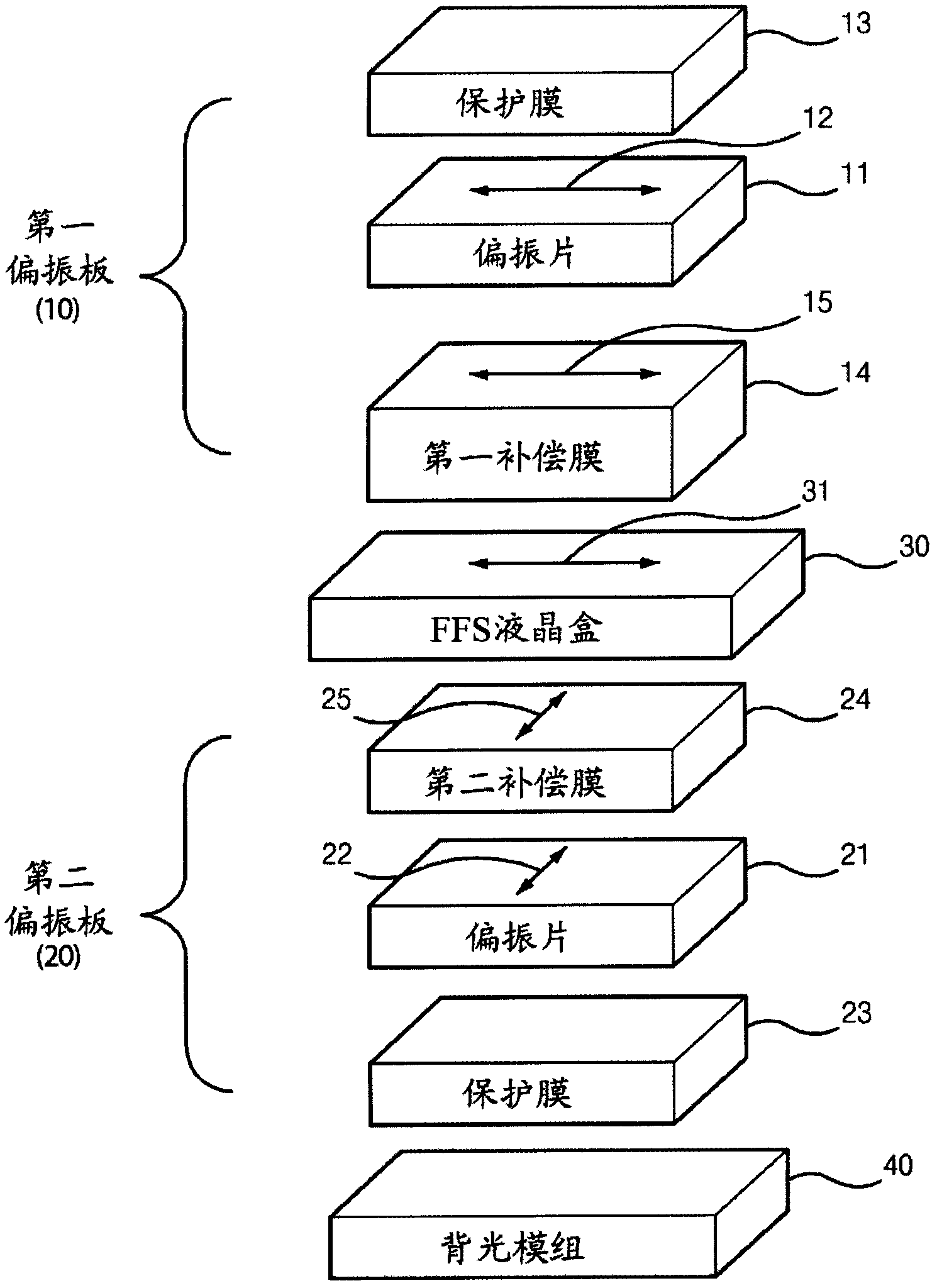

[0113] Although the configuration is the same as in example 1, in figure 2 In the stacked structure shown, the second compensation film 24 has an in-plane retardation (R0) of 270nm and a refractive index ratio (NZ) of -0.5, and the first compensation film 14 has an in-plane retardation (R0) of 60nm, -150nm The thickness direction retardation (Rth) and the refractive index ratio (NZ) of -2, and the in-plane switching mode liquid crystal display was fabricated using the second compensation film 24 and the first compensation film 14 . In this case, an in-plane switching mode liquid crystal cell 30 (FFS) whose liquid crystal orientation was 0° when measured counterclockwise from the right horizontal direction of the display in a state where no voltage was received was used.

[0114] Figure 9 showing the variation of the polarization state of an in-plane switching mode liquid crystal display on a Poincaré sphere at viewing angles of Φ=45° and θ=60° according to wavelength, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polarization | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com