Storage and transfer of organic nanofibers

An organic nanofiber, nanofiber technology, used in transportation and packaging, electrical components, circuits, etc., to solve storage-related problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

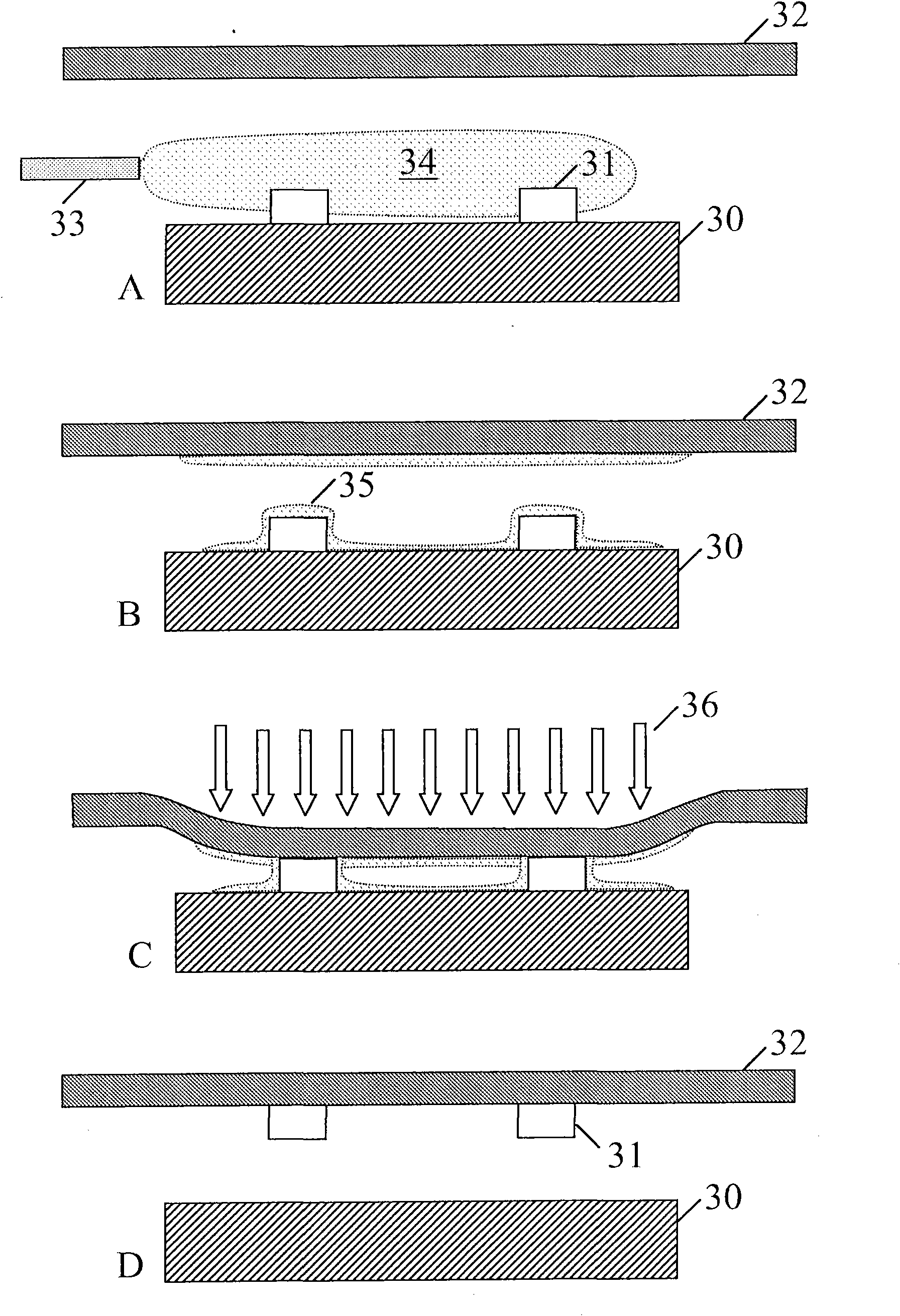

[0060] Embodiments of the invention relate to the transfer of nanofibers from a template substrate to a flexible storage medium. In a step prior to the transfer process, a template substrate loaded with nanofibers and a flexible storage medium are provided.

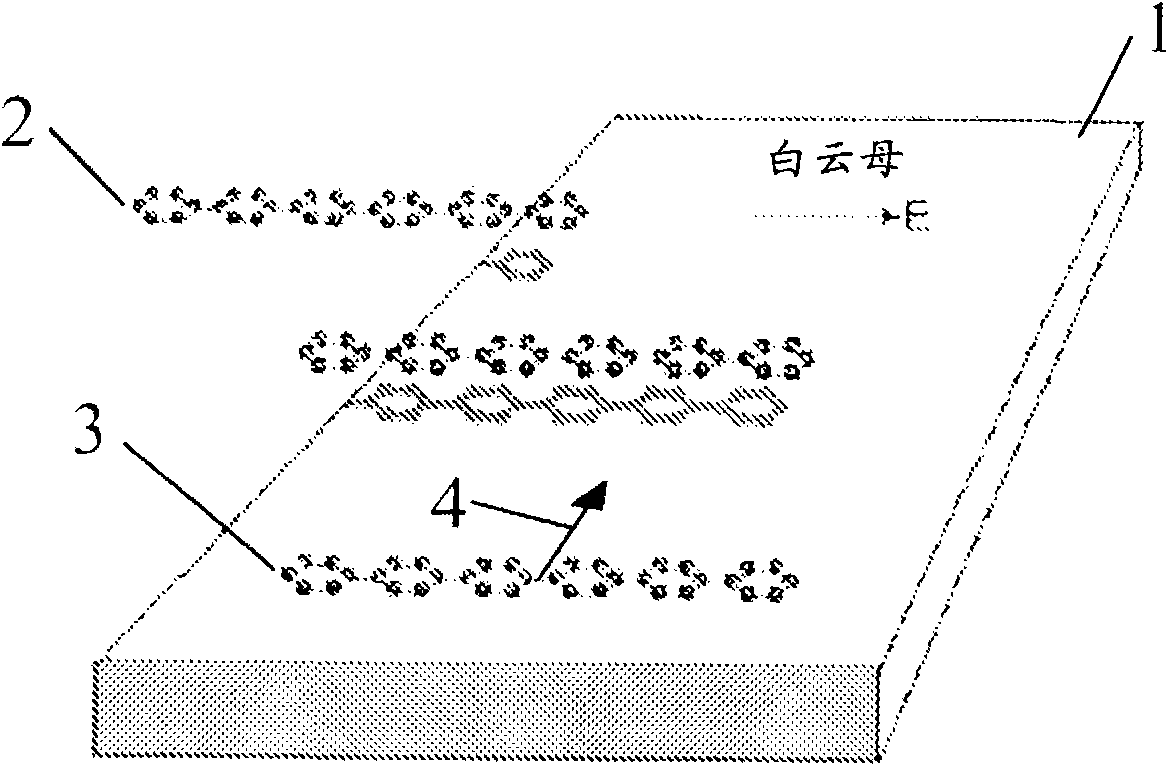

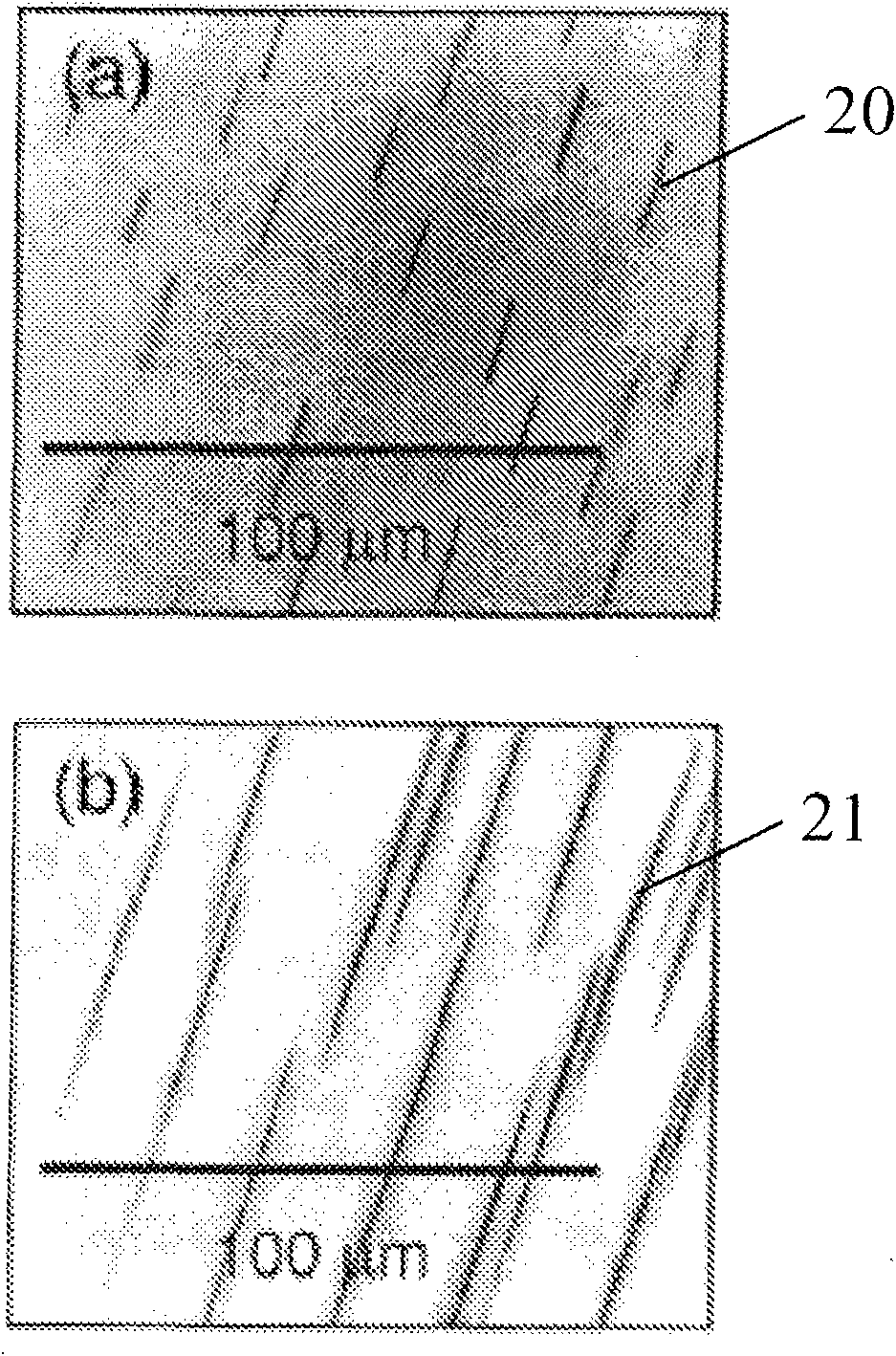

[0061] figure 1 and figure 2 A possible template substrate and an embodiment of nanofibers in the form of elongated arrays of nanofibers of organic molecules grown on a mica substrate are described.

[0062] figure 1 The growth of organic nanofibers2, 3 on a template substrate, or more specifically, the growth of phenylene nanofibers on a muscovite substrate, is briefly illustrated.

[0063] Mica can be prepared such that an electric field appears on the surface, for example by cleaving in air and immediately transferring to a vacuum device which can be degassed, for example at 410K for 0.5 hours or possibly longer; split directly.

[0064] The nanofibers presented in this section are made of p-phenylene oligomers (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com