Self-generation wide-band laminated magnetic induced piezoelectric effect AC magnetic field sensor and production method thereof

A technology of piezoelectric effect and AC magnetic field, which is applied in the field of new AC magnetic field sensors, can solve problems such as not forming sensors, and achieve the effects of enhanced sensitivity, high-frequency bandwidth, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

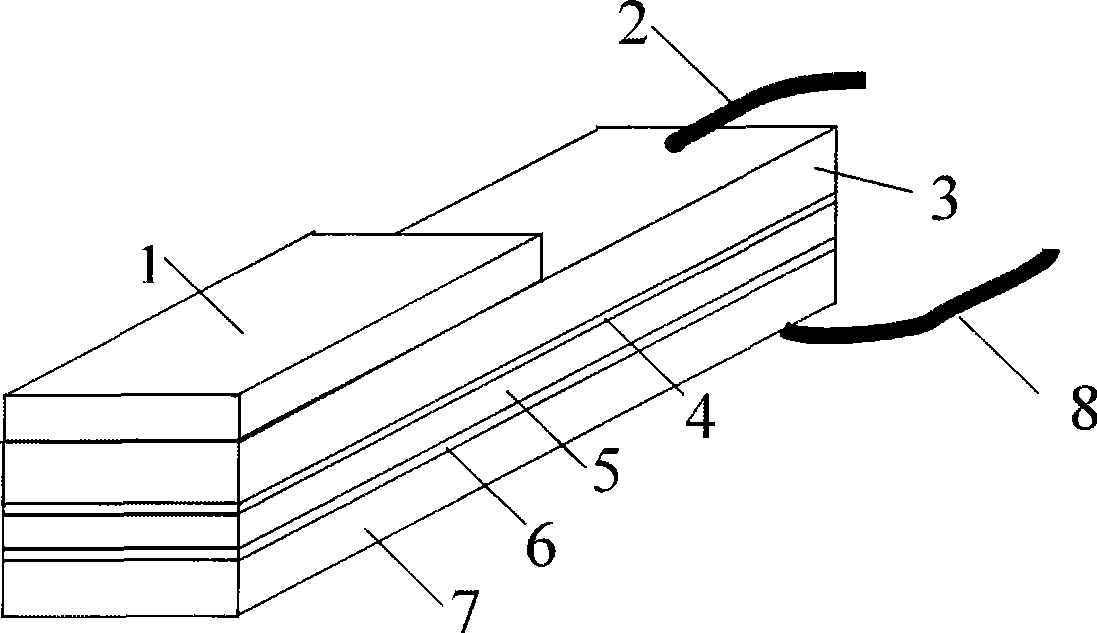

[0040] figure 1 The shown sensor was prepared as follows:

[0041] (1) Cut the large-sized Terfenol-D cylindrical rod to obtain Terfenol-D thin rod 3 and thin rod 7 with a length of 10 mm, a width of 1 mm, and a height of 1 mm. The opposite sides of the thin rod 3 and thin rod 7 are polished. ;

[0042](2) Make the same width as the Terfenol-D thin rod 3 described in (1), and the PZT-5H material 5 with a thickness of 0.8mm, silver-plated layers 4 and 6 respectively on the upper and lower surfaces of the piezoelectric material 5, use CLD- 5 Bake the conductive adhesive at 80°C for 30 minutes and raise the temperature to 120°C for 3 hours, then cool to room temperature, paste PZT-5H material 5 between Terfenol-D materials 3 and 7 to form Terfenol-D / piezoelectric material / Terfenol-D laminated structure, the PZT material is polarized with a strong electric field along the thickness direction, and the voltage signal is output through the signal output lines 2 and 8 on the thin r...

Embodiment 2

[0045] Use an Agilent33220A signal generator to generate a sinusoidal signal, and provide an excitation current to the Helmertz circle, thereby generating a simulated measured alternating magnetic field near the center of the Helmertz axis. Put the sensor made in Example 1 into this magnetic field, then The sensor will output an output voltage signal or charge signal that is proportional to the input alternating magnetic field. For laterally polarized PZT materials, the piezoelectric voltage coefficient reaches 35mV / Oe;

[0046] In the frequency range of 0.5 ~ 70KHz, the sensor output voltage remains unchanged under a constant input magnetic field. When the frequency increases to 80KHz, it is the resonance frequency point. At this time, the output voltage has a peak value. At this time, the dV / dH is very high, and the magnetic sensitivity can reach 1.5V / Oe during resonance.

[0047] The frequency of the alternating signal is between 0 and 500 Hz. When the input amplitude is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com