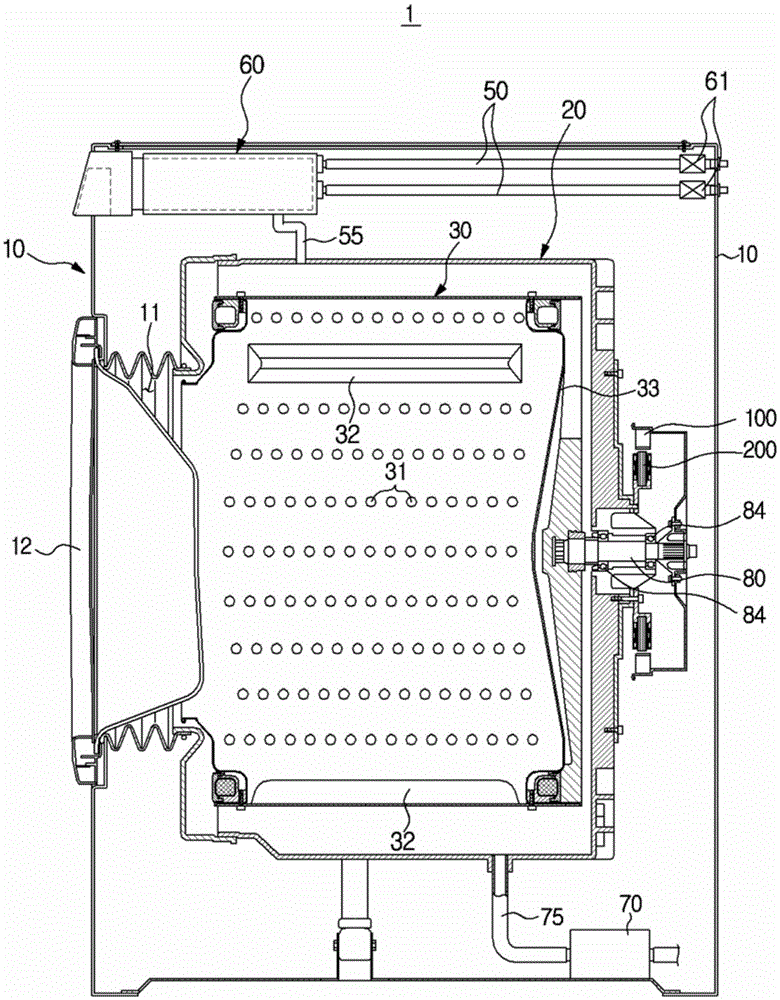

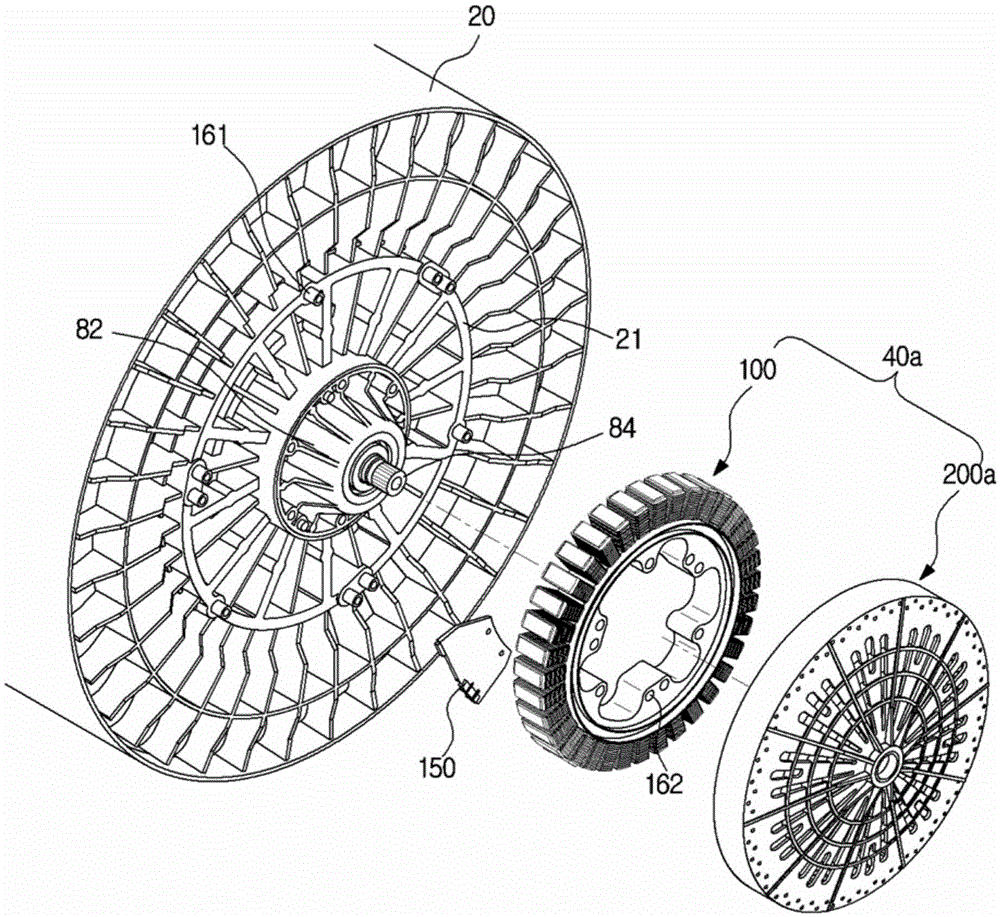

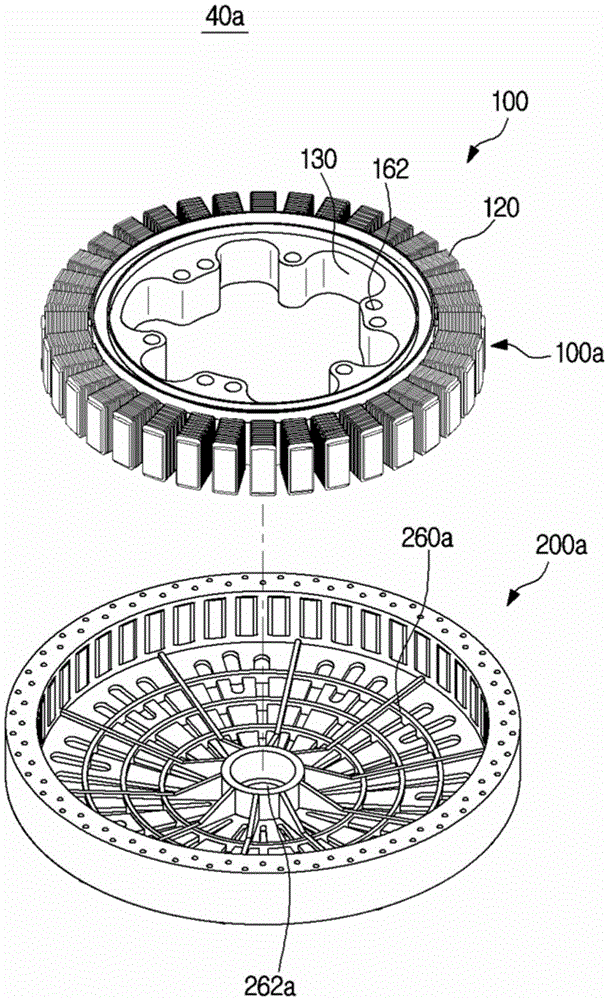

Rotor and method of manufacturing same

A technology of rotor and rotor core, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, electric components, etc., can solve problems such as reduction of magnetization efficiency and motor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, the present invention will be described in detail through embodiments described with reference to the accompanying drawings so that those of ordinary skill in the art can easily understand and practice the present invention. However, in describing the present invention, when detailed descriptions about known functions or components are considered to unnecessarily obscure the gist of the embodiments of the present invention, the detailed descriptions will be omitted.

[0055] The terms used below are terms that have been selected in consideration of the functions in the embodiments. The meanings of the terms may vary depending on the user's and operator's intention or practical experience. Therefore, terms used in the embodiments to be described below should be interpreted as specific meanings when the meanings are defined below, and as meanings commonly understood by those of ordinary skill in the art when no specific definition is given .

[0056] In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com